Microcrystalline and high corrosion resistance type titanium alloy pipe and preparation method thereof

A technology for titanium alloys and pipes, which is applied in the field of microcrystalline, high-strength, corrosion-resistant titanium alloy pipes and their preparation, which can solve problems such as low strength, complicated preparation methods, and coarse structures, and achieve good quality, high structure density, and crystal grains. small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

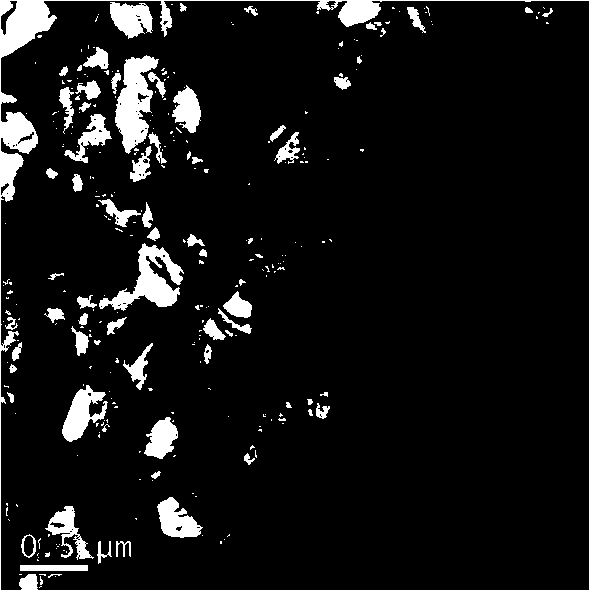

Image

Examples

Embodiment 1

[0028] (1) Forged tube billet: using sponge titanium Ti80 (brand Ti-6Al-3Nb-2Zr-1Mo) as raw material, the measured ratio of alloying elements is Al: 6.1%, Nb: 2.5%, Zr: 2.0%, Mo : 1.1%, Fe: 0.03%, Si: 0.02%, and the balance is Ti. It is smelted in a vacuum consumable furnace and smelted three times to achieve uniform composition. After 5 to 8 times of drawing-compression forging to form a blank, then peel off the skin to remove the 0.5-1mm surface layer to obtain a Ф92mm round tube blank, that is, the tube blank; the measurement found that the volume percentage of the β phase in the tube blank is less than 7%, which is close to α Titanium alloy;

[0029] (2) Preparation of capillary tube: send the tube billet into the annular heating furnace, heat it with the furnace to 995 ° C for 70 minutes, and then roll it through cross-rolling and piercing, and cool it by external spraying and internal spraying to make the capillary tube; it is found that the capillary tube The microstr...

Embodiment 2

[0035] (1) Forged tube billet: Ti80 (brand Ti-6Al-3Nb-2Zr-1Mo) is used as the sponge titanium raw material, and the ratio of alloy elements measured is Al: 6.0%, Nb: 2.4%, Zr: 1.9%, Mo : 0.9%, Fe: 0.04%, Si: 0.02%, and the rest is Ti. It is smelted in a vacuum consumable furnace and smelted three times to achieve uniform composition. After 5 to 8 times of drawing-compression forging to form a blank, then peel off the skin to remove the 0.5-1mm surface layer to obtain a Ф115mm round tube blank, that is, the tube blank; the measurement found that the volume percentage of the β phase in the tube blank is less than 7%, which is close to α Titanium alloy;

[0036] (2) Preparation of capillary tube: send the tube billet into the annular heating furnace, heat it to 1015°C and keep it for 70 minutes, then roll it through cross-rolling and piercing, and cool it by external spraying and internal spraying to make capillary tube; the measurement found that the microstructure of the capil...

Embodiment 3

[0042] (1) Forged tube billet: Ti80 (brand Ti-6Al-3Nb-2Zr-1Mo) is used as the sponge titanium raw material, and the measured chemical composition content (wt.%) of alloy elements is: Al: 6.0%, Nb: 2.8%, Zr : 2.0%, Mo: 1.1%, Fe: 0.03%, Si: 0.02%, and the rest is Ti. It is smelted in a vacuum consumable furnace and smelted three times to achieve the purpose of uniform composition. After 5 to 8 times of drawing-compression forging to form a blank, and then peel off the skin to remove the 0.5-1mm surface layer, the Ф96mm round tube billet is obtained, that is, the tube blank; the measurement found that the volume percentage of the β phase in the tube blank is less than 7%, which is close to α Titanium alloy;

[0043] (2) Preparation of capillary tube: send the tube billet into the annular heating furnace, heat it to 1030°C and keep it for 70 minutes, then roll it through cross-rolling and piercing, and cool it by external spraying and internal spraying to make the capillary tube; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com