Novel concrete module

A new type of concrete technology, which is applied in the field of new concrete modules, can solve the problems of module fracture, lack of high-strength and high-toughness support layer, easy to scratch the surface, etc., and achieve waterproof, wear-resistant, anti-skid, thermal conductivity, excellent comprehensive performance, and bonding good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

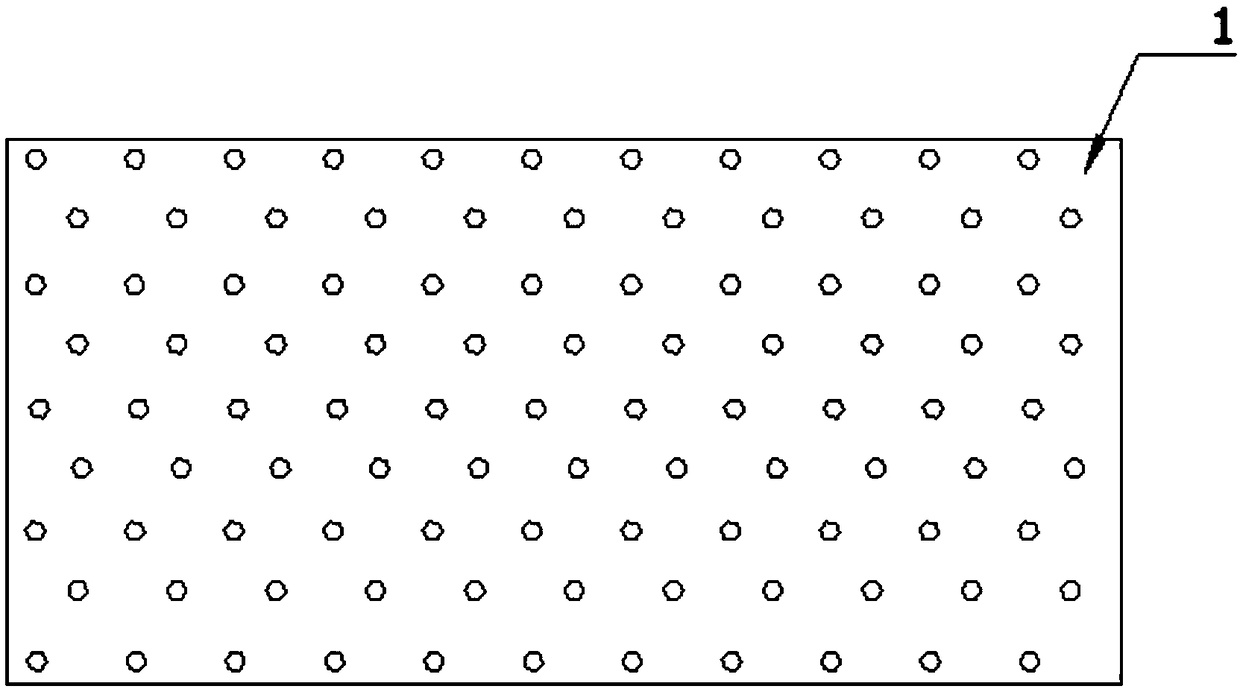

[0028]A new type of concrete module in this embodiment, the module includes a light-transmitting layer 1, a protective layer 2, a light functional layer 3, a heat-conducting layer 4, a stainless steel support layer 5, and an insulating moisture-proof layer 6 from top to bottom; The functional layer is a solar photovoltaic panel. The light-transmitting layer is made of the following raw materials in mass percentage: 5% AFG-90 epoxy resin, 20% TDE-85 epoxy resin, 10% bisphenol A type 128 resin, 15% epoxy resin curing agent, 40% % glass particles, 2% KH560 coupling agent, 3% KH512 coupling agent and 5% N,N-dimethylaniline; the particle diameter of the glass particles is 0.4-0.5mm.

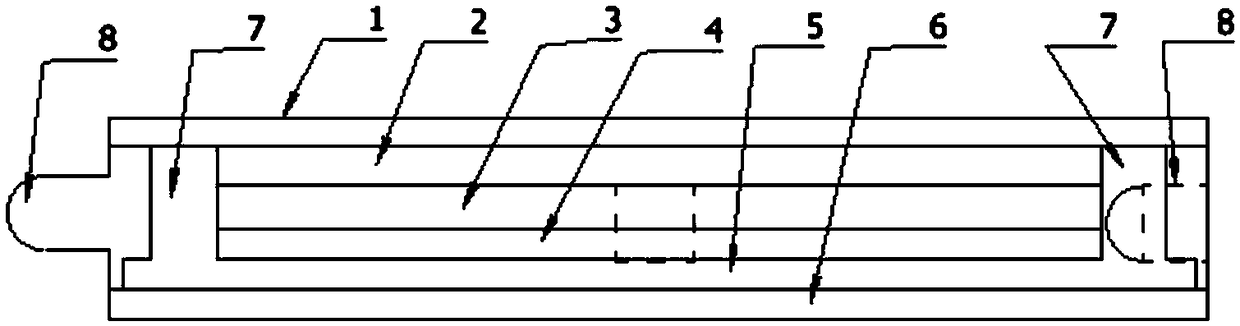

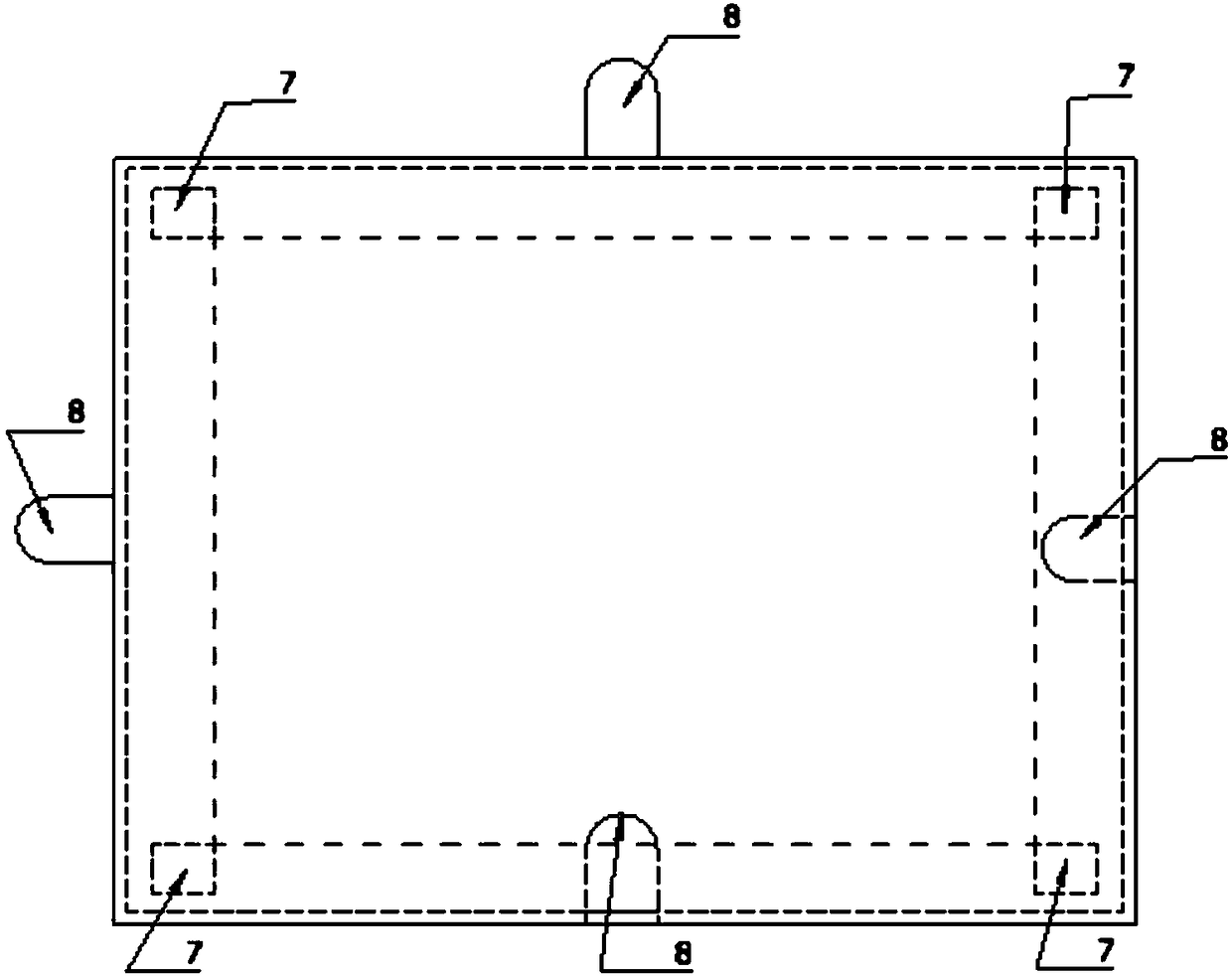

[0029] like Figures 1 to 3 As shown, the concrete module described in this embodiment is a cuboid with a length of 60 cm and a width of 40 cm; the four corners of the upper surface of the stainless steel support layer are respectively provided with a boss 7, and the height of the boss is equal to th...

Embodiment 2

[0037] Compared with Example 1, the upper surface of the light-transmitting layer described in this example is subjected to waterproof and wear-resistant treatment, and the following steps are adopted: (A) Nano-silica, dehydrated alcohol, and silane coupling agent KH570 with a particle diameter of 10-20 nm Mix with a mass ratio of 4:20:1, stir and disperse evenly to obtain a silica solution; (B) mix nano-zirconia with a particle size of 30-40nm, absolute ethanol, and silane coupling agent KH570 at a ratio of 4:40 : 3 mass ratio mixing, stirring and dispersing evenly to obtain a zirconium dioxide solution; (C) mixing the above-mentioned silicon dioxide solution, zirconium dioxide solution and hexamethyldisilazane with a mass ratio of 50:47:3, while pumping Stir and disperse evenly under vacuum to obtain a surface treatment solution; (D) spray the above-mentioned mixed treatment solution on the upper surface of the cleaned light-transmitting layer under high pressure, and dry; A...

Embodiment 3

[0041] Compared with Example 1, the thickness of the light-transmitting layer in this embodiment is 5 mm, and the upper surface of the light-transmitting layer is provided with some protrusions, the protrusions are parallel stripes, and the distance between adjacent raised stripes is 3 cm. The protrusion has a width of 3 mm and a height of 0.5 mm.

[0042] The light transmittance of the light-transmitting layer in this embodiment is 97.5%, and the surface friction coefficient is 0.78.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com