3D printing method of diamond drill bit with grinding aid structure

A diamond drill bit, 3D printing technology, applied in the direction of drill bit, earthwork drilling, drilling equipment, etc., can solve the problems of low efficiency, weak abrasiveness, difficult to drill into rock formations, etc., achieve excellent performance, increase drilling speed, consume drilling pressure little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

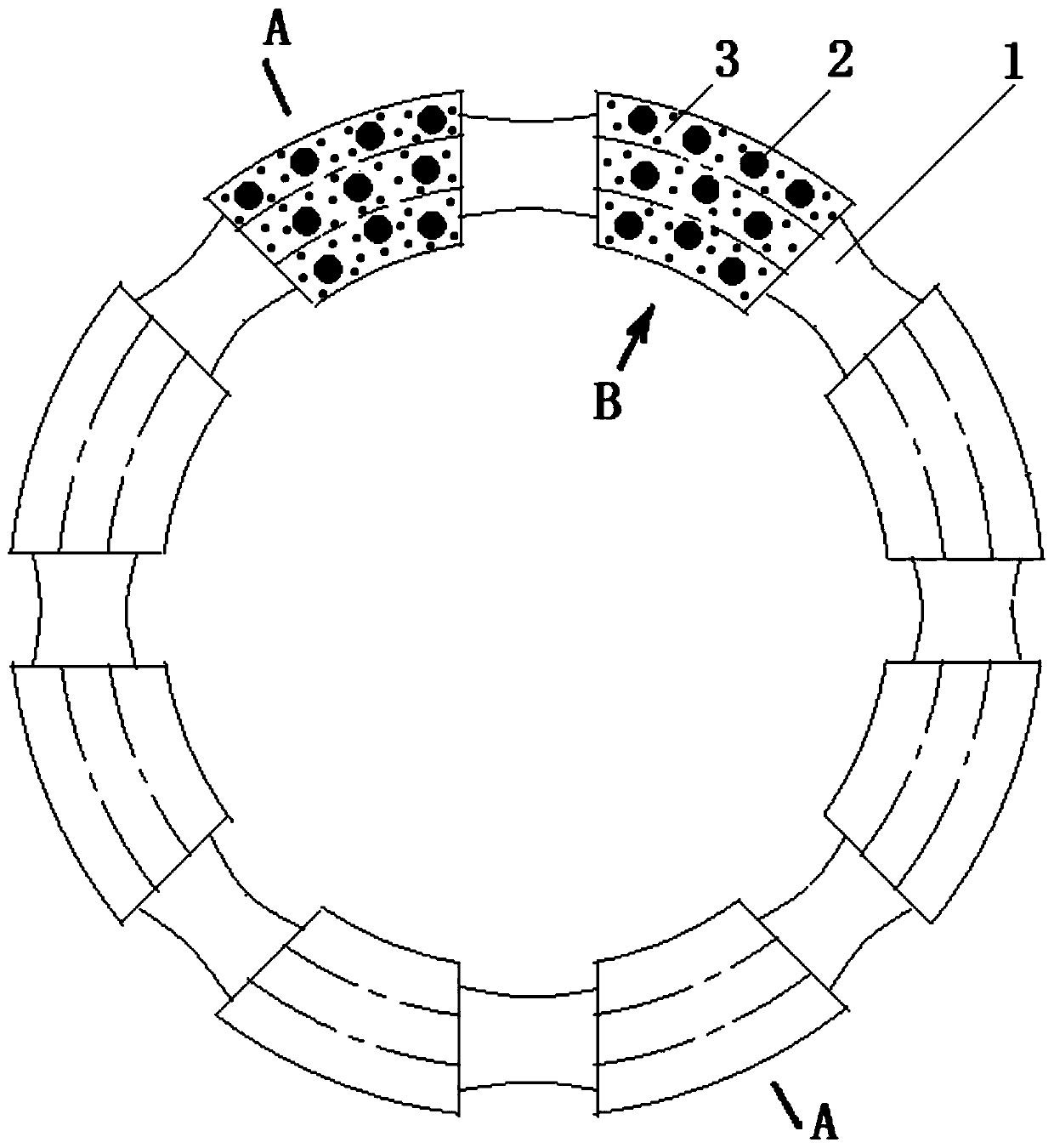

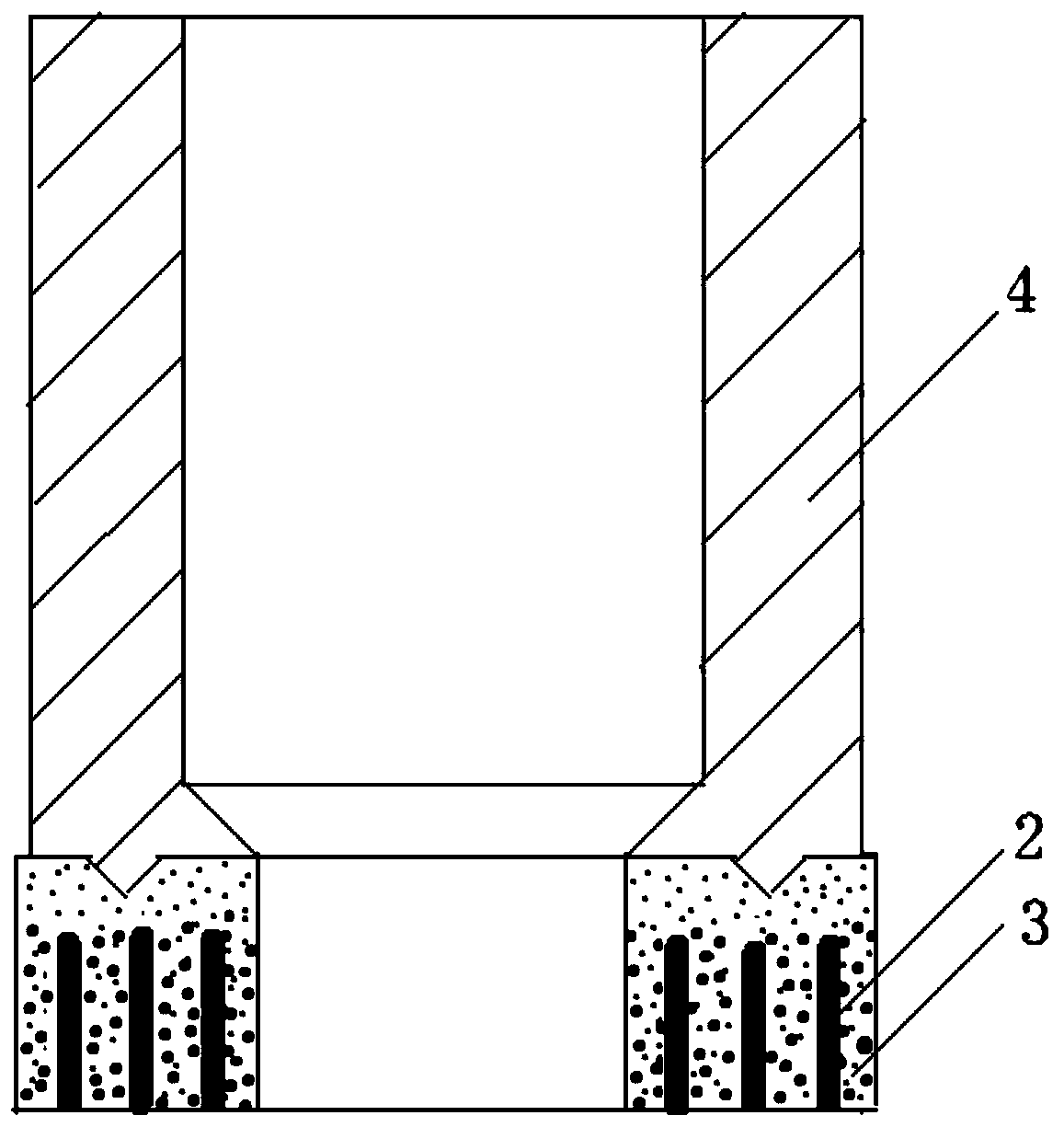

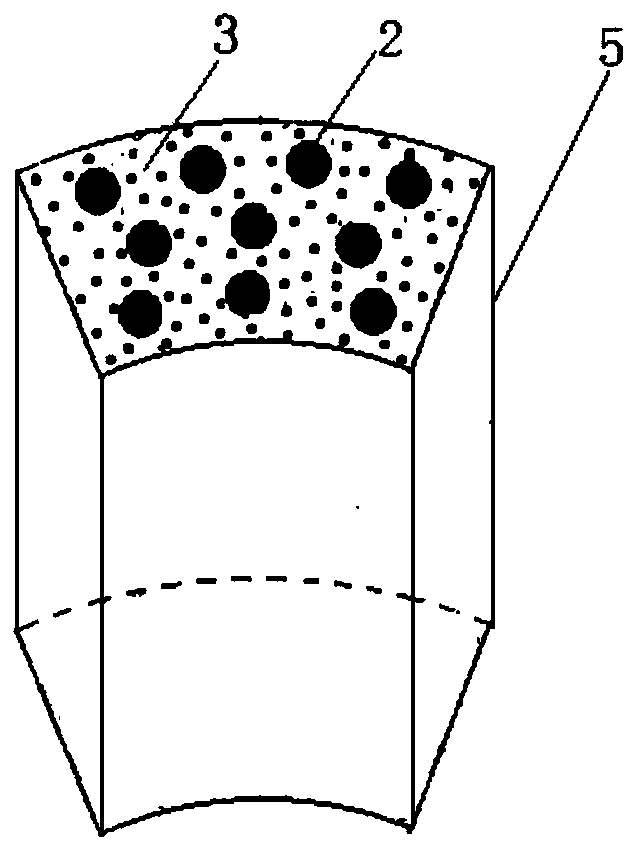

[0034] Please refer to Figure 1-3 , the embodiment of the present invention provides a diamond drill bit with a grinding aid structure, the drill bit includes a plurality of main working bodies 3 and a plurality of grinding aids 2 placed in the main working body, the grinding aids 2 and the main working body The working body 3 constitutes a drill fan-shaped working body 5 .

[0035] A plurality of main working bodies 3 are arranged at equal intervals along the circumferential direction of the bottom lip surface of the drill bit, and are located on the edge of the bottom lip surface. The Rockwell hardness of the main working bodies 3 is HRC12-25, and the wear resistance is ML (0.5-0.7)× 10 -5 , the main working body 3 is connected to the adjacent main working body through the nozzle 1.

[0036] A plurality of grinding aids 2 are arranged in the main working body 3 and are evenly distributed. Preferably, the grinding aids 2 are arranged on the radius of the bottom lip surface...

Embodiment 2

[0051] The difference between this embodiment and Example 1 is that the FAM-103 type pre-alloyed powder accounts for 68% of the main working body raw materials, the FAM-201 type pre-alloyed powder accounts for 32%, and the particle size of the diamond is 35 mesh to 40 mesh. The particle size of the alloy powder is 127μm, and the volume concentration of diamond is 22%. Among the grinding aid raw materials, FAM-201 type pre-alloyed powder accounts for 70%, FAM-202 type pre-alloyed powder accounts for 30%, and the particle size of silicon carbide is 45 mesh. ~50 mesh, the volume concentration of silicon carbide is 8%; the parameters of the forming drill bit of the laser selective melting equipment are: laser power 220W, scanning speed 700mm / s, scanning distance 0.06mm, powder coating thickness 0.5mm. The rest are basically the same as in Example 1.

Embodiment 3

[0053] The difference between this embodiment and Example 1 is only that the FAM-103 type pre-alloyed powder accounts for 72% of the main working body raw materials, the FAM-201 type pre-alloyed powder accounts for 28%, and the particle size of the diamond is 50 mesh to 60 mesh. The volume concentration of the pre-alloyed powder is 20%, and the particle size of the pre-alloyed powder is 80 μm; the FAM-201 type pre-alloyed powder accounts for 65%, the FAM-202 type pre-alloyed powder accounts for 35%, and the particle size of the silicon carbide is 50 mesh to 60 The volume concentration of silicon carbide is 10%, the particle size of the pre-alloyed powder is 127μm; the parameters of the forming drill bit of the laser selective melting equipment are: laser power 200W, scanning speed 800mm / s, scanning distance 0.07mm, powder coating thickness 0.40 mm. The rest are basically the same as in Example 1.

[0054] The main working body of the diamond drill bit of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com