Preparation method of molybdenum phosphide catalysts

A molybdenum phosphide catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of cumbersome steps, high temperature required, difficult to reduce phosphate, etc., and achieve simple equipment, Low price, small particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

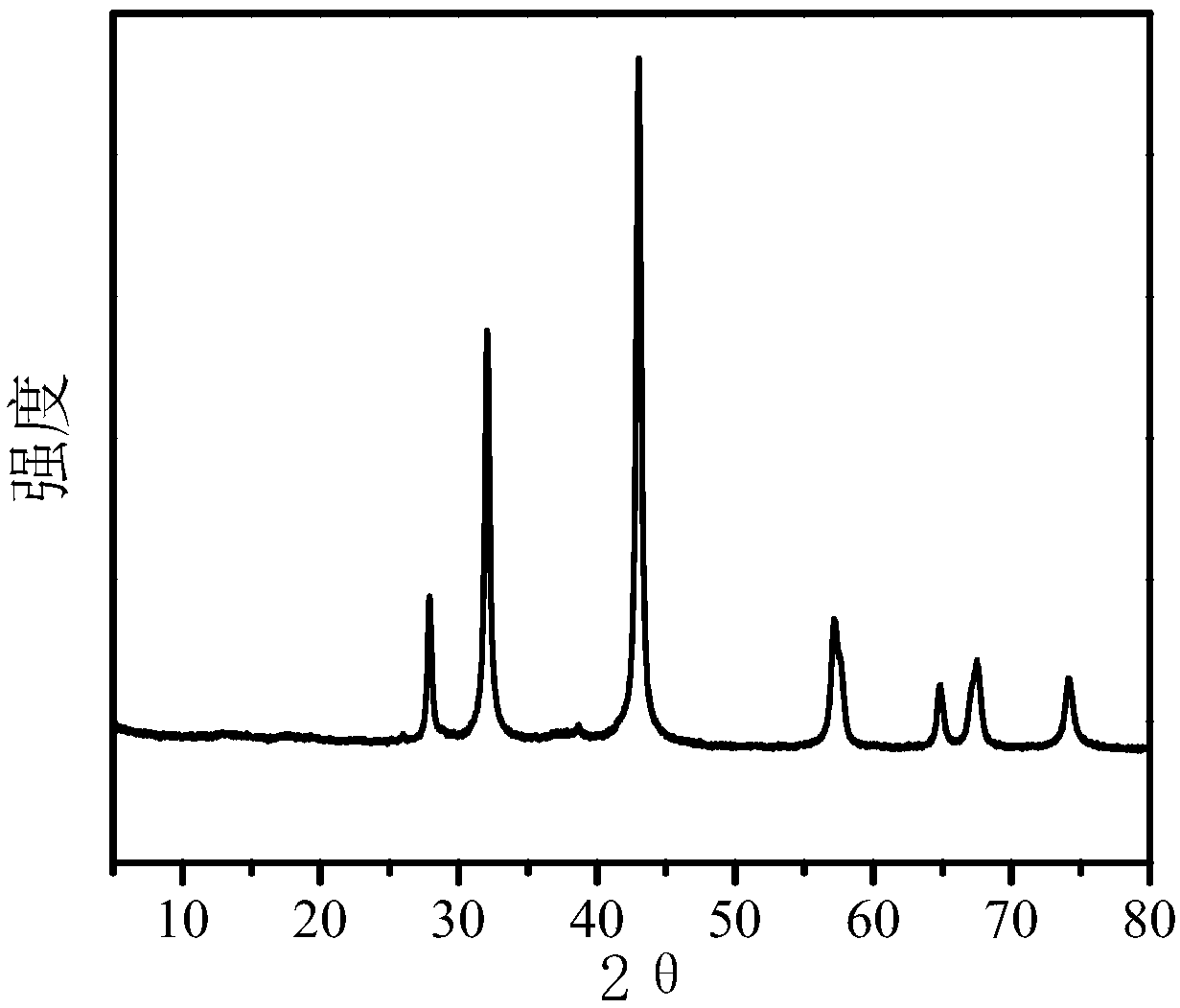

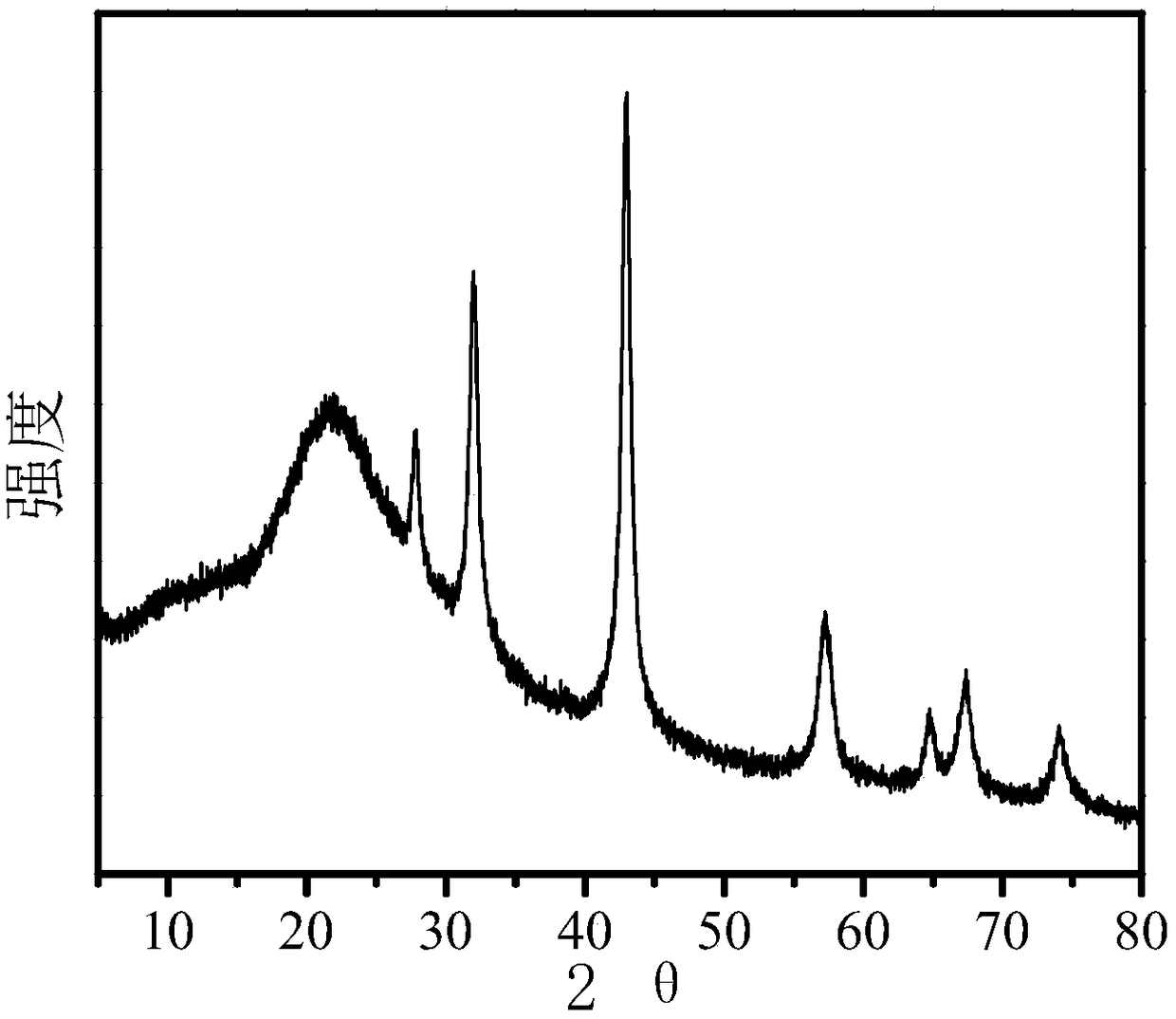

Embodiment 1

[0022] First, dissolve 9g of molybdenum trioxide and 5.4g of ammonium hypophosphite in 20mL of ammonia water at room temperature, stir for 30 minutes and dissolve to a clear solution. The solution is dried at room temperature for 10 hours and then placed in an oven at 60°C for drying. The obtained white solid was ground into powder and then put into a quartz reactor and reduced by passing hydrogen gas. The hydrogen flow rate was maintained at 100 mL / min. The quartz reactor is heated from room temperature to 550°C with a heating rate of 2°C / min. Hold at 550°C for 3 hours. After the reduction, the unsupported MoP catalyst was obtained by naturally cooling to room temperature.

Embodiment 2

[0024] Firstly, 9g of molybdenum trioxide and 8.1g of ammonium hypophosphite were dissolved in 20mL of ammonia water at room temperature, stirred for 20min and then dissolved into a clear solution. The solution was dried at room temperature for 24 hours and then placed in an oven at 50°C for drying. The obtained white solid was ground into powder and then put into a quartz reactor and reduced by passing hydrogen gas. The hydrogen flow rate was maintained at 100 mL / min. The quartz reactor is heated from room temperature to 600°C with a heating rate of 2°C / min. Hold at 600°C for 3 hours. After the reduction, the unsupported MoP catalyst was obtained by naturally cooling to room temperature.

Embodiment 3

[0026] Firstly, 9g of molybdenum trioxide and 8.1g of ammonium hypophosphite were dissolved in 20mL of ammonia water at room temperature, stirred for 40 minutes, and then dissolved into a clear solution. The solution was dried at room temperature for 6 hours and then dried in an oven at 70°C. The obtained white solid was ground into powder and then put into a quartz reactor and reduced by passing hydrogen gas. The hydrogen flow rate was maintained at 150 mL / min. The quartz reactor was heated from room temperature to 600°C with a heating rate of 1°C / min. Hold at 600°C for 3 hours. After the reduction, the unsupported MoP catalyst was obtained by naturally cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com