Organic waste low-temperature in-situ degradation reaction device and application

A technology for organic waste and degradation reaction, which is applied in the field of low-temperature in-situ degradation reaction devices for organic waste, can solve the problems of high comprehensive treatment cost and operation cost, long microbial treatment cycle, and increase comprehensive treatment cost, and save energy consumption. , Shorten the degradation time, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

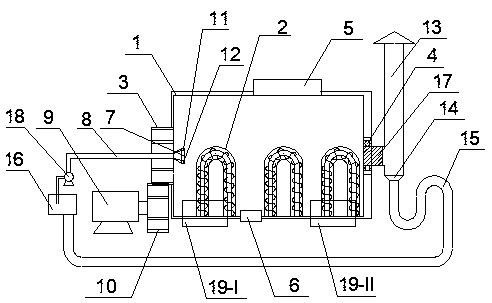

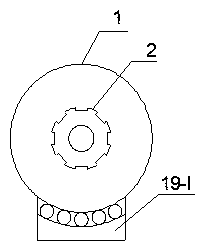

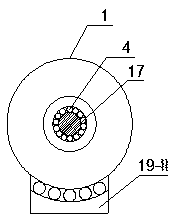

[0026] A low-temperature in-situ degradation reaction device for organic waste. The device is composed of a magnetic pulse reactor, a rotating device, a temperature measuring device, a humidity measuring device, a water supply device, an exhaust pipeline and a liquid discharge port. The magnetic pulse reactor includes Box 1, magnetic pulse heating pipeline 2, the inside of the magnetic pulse heating pipeline is a copper coil winding iron core, and the outside is covered with ceramics. The box 1 is a horizontal cylinder and is made of 304 stainless steel. The gear 3 is connected with the rotating device, and the corresponding position on the other side is connected with the exhaust pipeline and the connection is a ball bearing 4, and the box is provided with a material inlet 5 and an outlet 6; The nozzle 8 is composed of the liquid feeding pipeline 7 entering the magnetic pulse reactor, and the atomizing nozzle 8 is arranged at the liquid outlet; the rotating device includes a m...

Embodiment 2

[0030] An application of a low-temperature in-situ degradation reaction device for organic waste, which uses the magnetothermal conversion treatment method of adding organic waste once to carry out the degradation reaction of organic matter. The steps are as follows:

[0031] 1) Add organic waste from food waste directly to the reaction device and start the device;

[0032] 2) Under the action of the electromagnetic field, the convection effect is continuously generated and accumulated through the pulsed electromagnetic field, thereby forming a local high temperature, and the material is rapidly heated to 180°C;

[0033] 3) Use the thermometer and hygrometer to display the temperature and humidity of the material, use the thermometer to maintain the electromagnetic strength through program control, so as to maintain the system temperature stability, use the liquid addition pipeline to replenish water to keep the humidity at 7%, and add water when adding water The aperture of t...

Embodiment 3

[0038] An application of a low-temperature in-situ degradation reaction device for organic waste, which uses the magnetothermal conversion treatment method of adding organic waste once to carry out the degradation reaction of organic matter. The steps are as follows:

[0039] 1) Add landscaping waste and kitchen waste with a particle size not greater than 10cm directly into the reaction device at a weight ratio of 1:2, and start the device;

[0040] 2) Under the action of the electromagnetic field, the convection effect is continuously generated and accumulated through the pulse electromagnetic, thereby forming a local high temperature, and the material is rapidly heated to 170°C;

[0041] 3) Use the thermometer and hygrometer to display the temperature and humidity of the material, use the thermometer to maintain the electromagnetic strength through program control, so as to maintain the system temperature stability, use the liquid addition pipeline to replenish water to keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com