Forming agent, feeding material, preparation method of feeding material, green body and the preparation method of green body

A forming agent and feeding technology, which is applied in the fields of feeding and its preparation method, green body and its preparation, and forming agent, can solve the problems of environmental pollution, complex solvent or acid degreasing process, etc., and achieve pollution reduction and simple use process , Degreasing process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

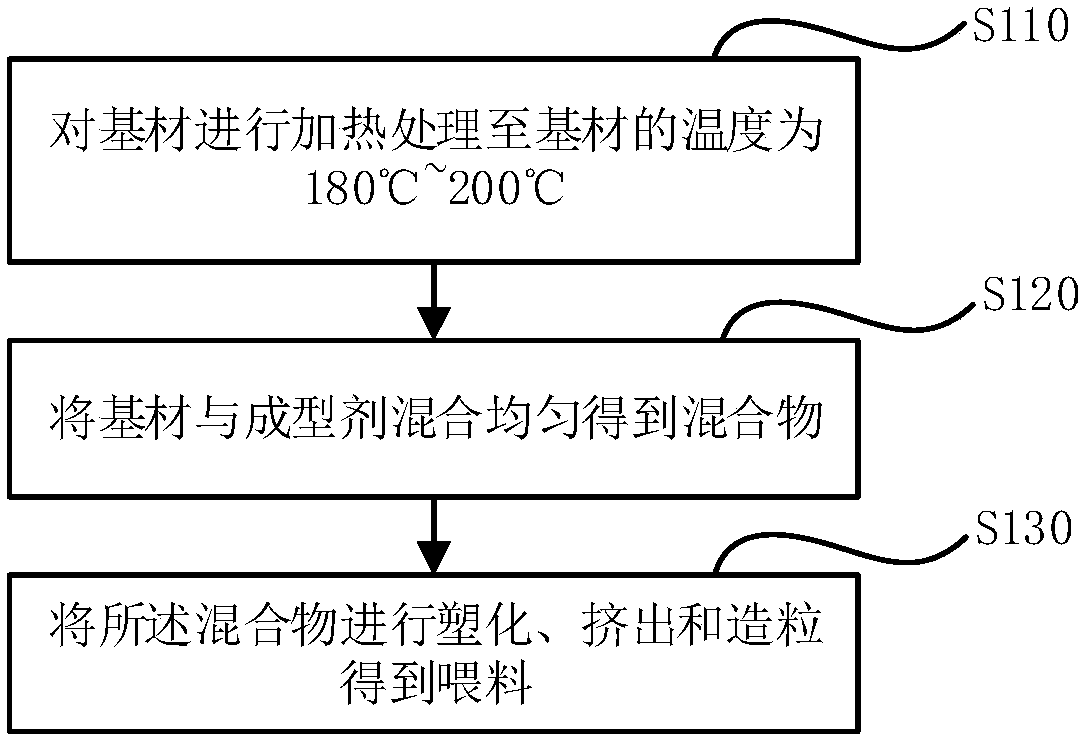

[0043] see figure 1 , the preparation method of the feed of an embodiment, comprises the following steps:

[0044] S110 , heat-treating the substrate until the temperature of the substrate is 180° C. to 200° C.

[0045] In one embodiment, the substrate is selected from at least one of metal powder and ceramic powder. Further, the metal powder may be at least one of titanium alloy powder, steel alloy powder, iron alloy and molybdenum metal.

[0046] In one embodiment, the base material is titanium alloy powder, and the heat treatment is carried out in a protective gas atmosphere or under vacuum conditions.

[0047] In one embodiment, the particle size of the substrate is 40nm-50nm.

[0048] S120, uniformly mixing the base material and the molding agent to obtain a mixture.

[0049] The molding agent is added into the heated titanium alloy and mixed until it becomes a muddy dough to obtain a mixture. During mixing, the temperature is maintained at 160°C to 190°C. The mixin...

Embodiment 1

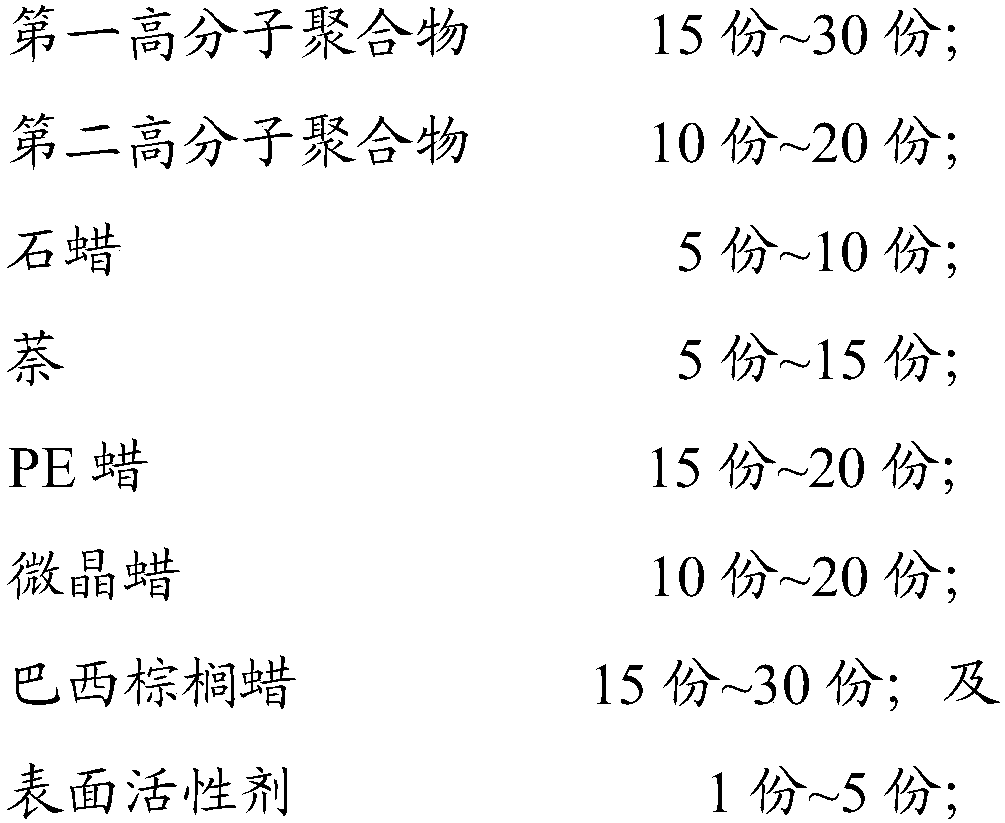

[0065] Weigh 1.5Kg of polyoxymethylene, 2Kg of polypropylene, 0.5Kg of liquid paraffin, 1.5Kg of naphthalene, 1.5Kg of PE wax, 2Kg of microcrystalline wax, 1.5Kg of carnauba wax and 0.5Kg of stearic acid and mix evenly to obtain Forming agent. Take 95Kg of 316L type metal powder and add in the internal mixer, and the internal mixer is vacuumized. The 316L type metal powder is heat treated to a temperature of 180°C. Then weigh 5Kg of the above-mentioned molding agent, add the molding agent into the internal mixer, and keep the temperature at 180°C for mixing until a uniform muddy mixture is formed. The rotating speed of internal mixer is set as 10r / min, and the time of mixing in internal mixer is 60min to obtain feeding.

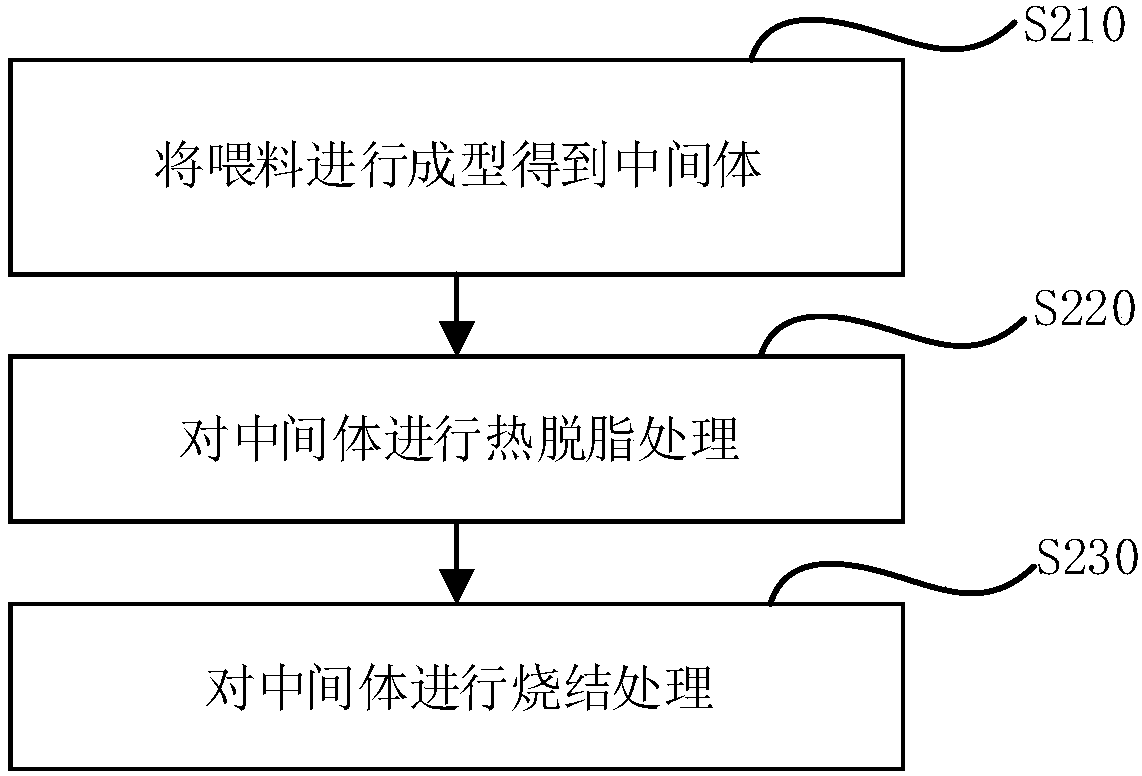

[0066] The selected product mold is installed in the injection molding equipment, and the feed material is injected into the injection molding equipment for injection molding to obtain an intermediate. The intermediate is thermally degreased. The intermed...

Embodiment 2

[0068] Weigh 3Kg of polyoxymethylene, 1Kg of polyethylene, 1Kg of liquid paraffin, 0.5Kg of naphthalene, 2Kg of PE wax, 1Kg of microcrystalline wax, 3Kg of carnauba wax and 0.1Kg of oleic acid and mix them uniformly to obtain a molding agent. Weigh 85Kg of 17-4PH type metal powder and add it into the internal mixer, and vacuumize the internal mixer. The 17-4PH type metal powder is heat treated to a temperature of 200°C. Then weigh 15Kg of the above-mentioned molding agent, add the molding agent into the internal mixer, and keep the temperature at 200°C for mixing until a uniform mud-like mixture is formed. The rotating speed of internal mixer is set as 30r / min, and the time of mixing in internal mixer is 120min to obtain feeding.

[0069] The selected product mold is installed in the injection molding equipment, and the feed material is injected into the injection molding equipment for injection molding to obtain an intermediate. The intermediate is thermally degreased. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com