High salinity wastewater treatment method and treatment system

A technology for high-salt wastewater and a treatment method, applied in the field of water treatment, can solve the problems of increasing the operation and maintenance cost of the process system, decreasing the membrane flux of the separation membrane element, and scrapping the membrane separation element, so as to reduce the investment in fixed assets and the number of membrane modules. The effect of reducing and preventing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

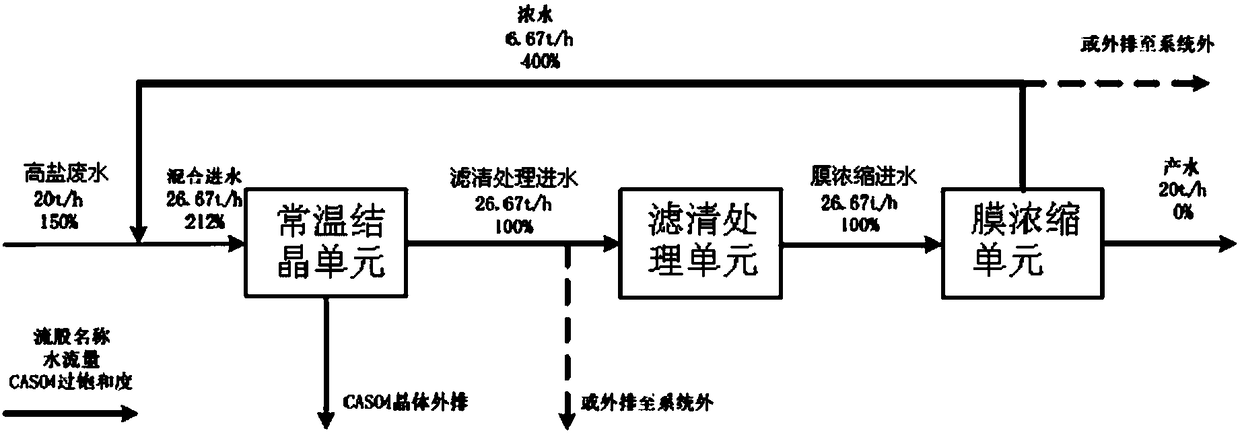

[0059] combine figure 1 , This embodiment is used to illustrate the treatment method of high-salt wastewater of the present invention.

[0060] (1) 6.67T / h that 20T / h, calcium sulfate supersaturation is 150% high-salinity waste water and step (3) obtain, calcium sulfate supersaturation is 400% concentrated water after mixing as mixed influent ( Calcium sulfate supersaturation is 212%) carry out normal temperature crystallization treatment with the total flow rate of 26.67T / h, wherein, normal temperature crystallization treatment is in the polyacrylamide (purchased from Nalco Company, trade mark is 8103PLUS, the same below) in the presence of calcium sulfate crystals (outflow) and 26.67T / h, calcium sulfate supersaturation is 100% normal temperature crystallization effluent;

[0061] (2) Adopting an ultrafiltration membrane with a pore diameter of 6 μm under 0.5MPa, the normal temperature crystallization effluent with 26.67T / h and calcium sulfate supersaturation of 100% is subj...

Embodiment 2

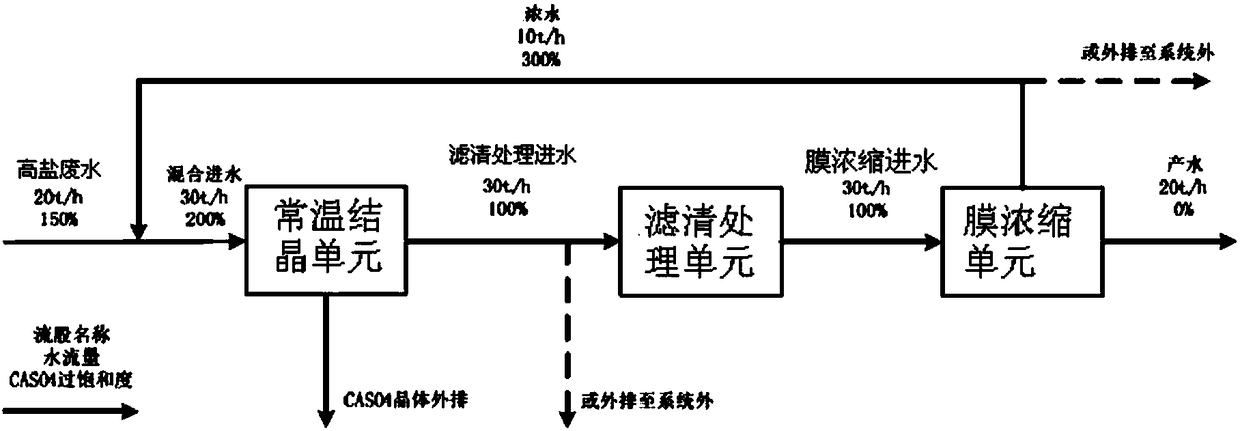

[0064] combine figure 2 , This embodiment is used to illustrate the treatment method of high-salt wastewater of the present invention.

[0065] (1) 20T / h, calcium sulfate supersaturation be 150% high-salt waste water and the 10T / h that step (3) obtains, calcium sulfate supersaturation are 300% concentrated water after mixing as mixed influent (sulfuric acid Calcium supersaturation is 200%) carry out normal temperature crystallization treatment with the total flow rate of 30T / h, wherein, normal temperature crystallization treatment is carried out under the polyacrylamide existence of the calcium hydroxide of 6% by weight and 65ppm, obtains calcium sulfate crystal (outflow ) and 30T / h, calcium sulfate supersaturation is 100% normal temperature crystallization effluent;

[0066] (2) Using an ultrafiltration membrane with a pore size of 6 μm, the 30T / h, calcium sulfate supersaturation of 100% normal temperature crystallization effluent is subjected to ultrafiltration at 0.8MPa t...

Embodiment 3

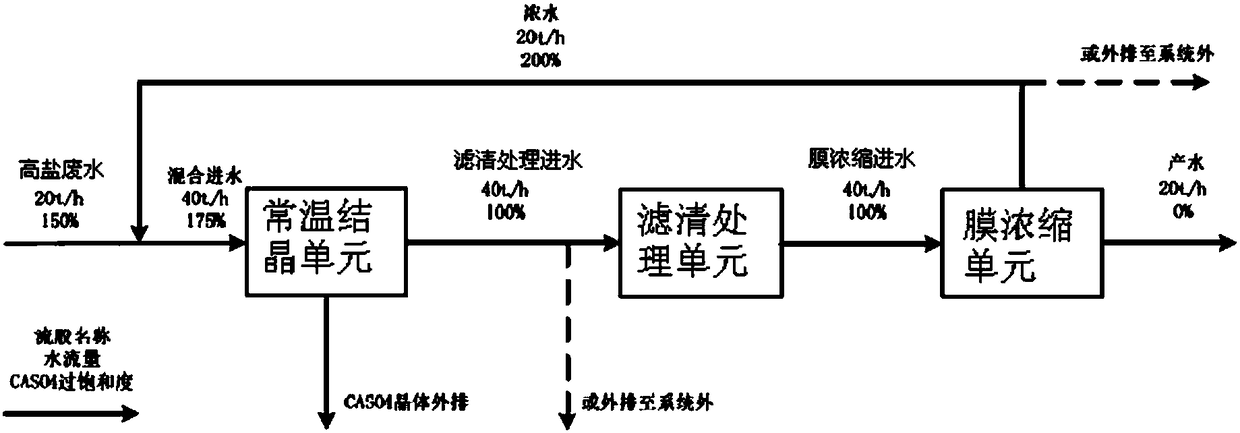

[0069] combine image 3 , This embodiment is used to illustrate the treatment method of high-salt wastewater of the present invention.

[0070] (1) 20T / h, calcium sulfate supersaturation is 150% high-salinity waste water and the 20T / h that step (3) obtains, calcium sulfate supersaturation is 200% concentrated water after mixing as mixed influent (sulfuric acid) Calcium supersaturation is 175%) carry out normal temperature crystallization treatment with the total flow rate of 40T / h, wherein, normal temperature crystallization treatment is carried out under the polyacrylamide presence of the sodium hydroxide of 7% by weight and 80ppm, obtains calcium sulfate crystal (outflow ) and 40T / h, calcium sulfate supersaturation is 100% normal temperature crystallization effluent;

[0071] (2) Using an ultrafiltration membrane with a pore size of 6 μm, the 40T / h, calcium sulfate supersaturation of 100% normal temperature crystallization effluent is subjected to ultrafiltration at 0.6MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com