Processing method of buckwheat drink

A processing method and technology of buckwheat, applied in food ingredients as clouding agent, food science and other directions, can solve the problems of rough taste, weak stability, easy oxidation of whole grain beverages, etc., to promote rapid dissolution, good suspension stability, The effect of maintaining suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

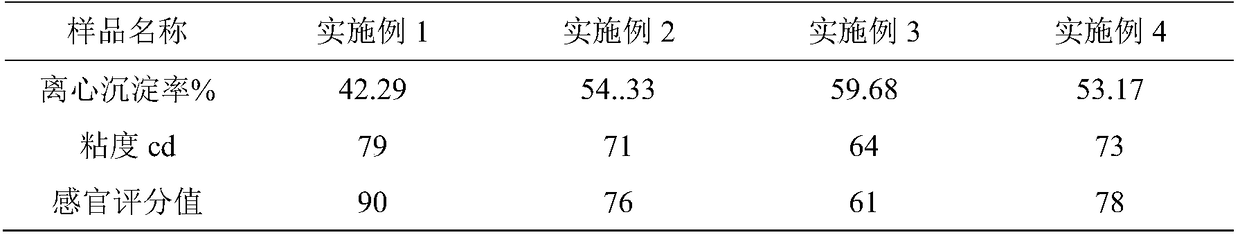

Embodiment 1

[0021] (1) Raw material processing: Weigh 24.2kg of buckwheat, 5.5kg of wheat, and 1.6kg of japonica rice, pass through a 100-mesh sieve after crushing, and obtain material A;

[0022] (2) Modification and stabilization of porous grain structure: Material A is subjected to superheated steam expansion at a temperature of 167°C and a pressure of 3.1 MPa for 6 minutes, then the pressure is released to normal pressure within 0.4s, and ultrafine pulverization is carried out to obtain Cereal flour B with a particle size of less than 22 μm;

[0023] (3) Preparation of solubilizing stabilizer

[0024] a. Dissolve 4.5kg of konjac starch in 7kg of water, adjust the pH to 5.3, heat and stir until the starch is completely gelatinized, cool to 50°C, add 182ml of pullulanase with an enzyme activity of 200u / ml, and enzyme at 50°C After 28 hours of freeing the branch, after the reaction, the enzyme was eliminated and dried to obtain konjac linear dextrin C;

[0025] b. Slowly add 1.9kg of p...

Embodiment 2

[0032] (1) Raw material processing: Weigh 24.2kg of buckwheat, 5.5kg of wheat, and 1.6kg of japonica rice, pass through a 100-mesh sieve after crushing, and obtain material A;

[0033] (2) Preparation of solubilizing stabilizer

[0034] a. Dissolve 4.5kg of konjac starch in 7kg of water, adjust the pH to 5.3, heat and stir until the starch is completely gelatinized, cool to 50°C, add 182ml of pullulanase with an enzyme activity of 200u / ml, and enzyme at 50°C After 28 hours of freeing the branch, after the reaction, the enzyme was eliminated and dried to obtain konjac linear dextrin C;

[0035] b. Slowly add 1.9kg of polyethylene glycol, 1.9kg of propanol, and 1.9kg of methanol to konjac linear dextrin C, stir at 27°C for 34min, settle at 5°C for 27h, and centrifuge to obtain filter cake 1 ;

[0036] c. Add 1.5 kg of polyethylene glycol, 1.5 kg of isopropanol, and 1.5 kg of methanol to filter cake 1, stir at 30°C for 40 minutes, settle at 3°C for 24 hours, and centrifuge to...

Embodiment 3

[0042] (1) Raw material processing: Weigh 24.2kg of buckwheat, 5.5kg of wheat, and 1.6kg of japonica rice, pass through a 100-mesh sieve after crushing, and obtain material A;

[0043] (2) Modification and stabilization of porous grain structure: Material A is subjected to superheated steam expansion at a temperature of 167°C and a pressure of 3.1 MPa for 6 minutes, then the pressure is released to normal pressure within 0.4s, and ultrafine pulverization is carried out to obtain Cereal flour B with a particle size of less than 22 μm;

[0044] (4) Blending and homogenizing: take grain powder B and 0.15 kg of xylitol, set the volume to 500 kg with drinking water, stir evenly, and homogenize 3 times, the homogenization temperature is 45°C, and the pressure is 26MPa;

[0045] (5) Sterilization and filling: The homogenized slurry is subjected to high-temperature instantaneous sterilization under the condition of 121°C for 10 minutes, and the aseptic filling technology is used for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com