Refining process for high-temperature rapid separation of inositol filtrate

A high-temperature, fast, inositol technology, which is applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of low inositol yield, high inositol conductivity, and low production efficiency, so as to increase the yield of inositol , Improve the purity of inositol, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

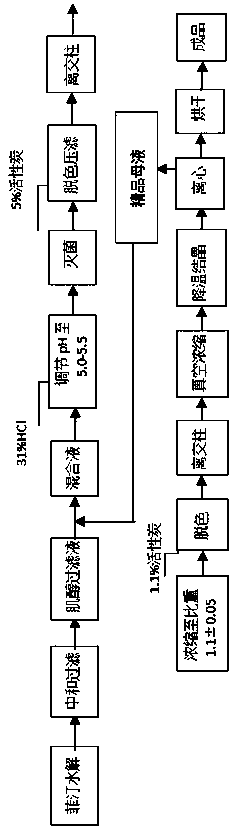

Method used

Image

Examples

Embodiment

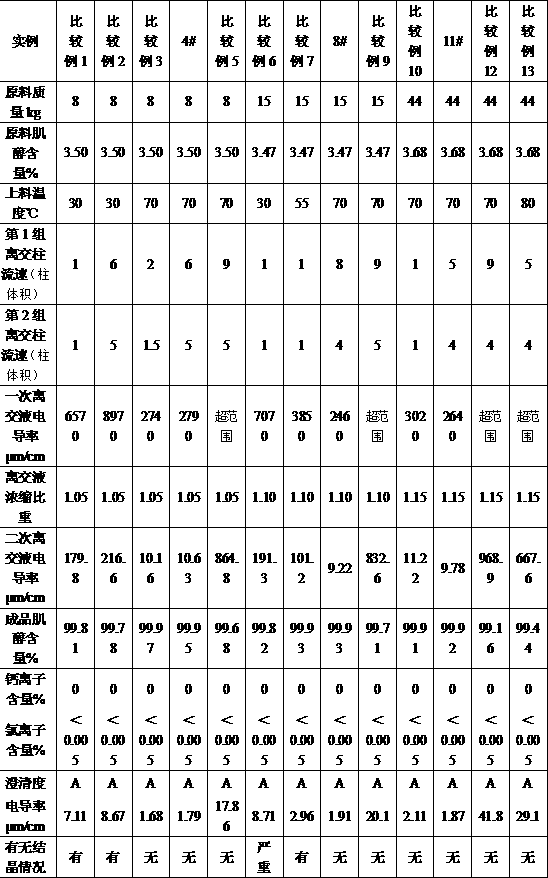

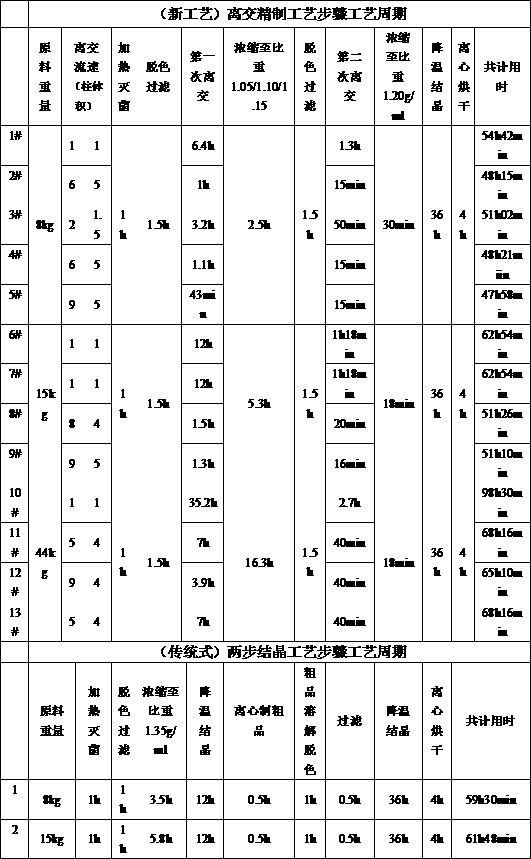

[0037] The preparation method of mixed solution in the following examples is:

[0038]According to the solid / liquid ratio of 1:4, phytin was added with clear water, stirred in a pressurized stirring hydrolysis tank and heated to 180 ° C, the pressure was 0.8 MPa, and hydrolyzed at this temperature and pressure for 6 hours to obtain inositol hydrolysis liquid. Hydraulically hydrolyze inositol into the neutralization tank, that is, neutralize it with 15% calcium hydroxide solution to a pH value of 8-10. And filter the neutralized solution to obtain the inositol filtrate. Mix the inositol filtrate and the fine mother liquor at a ratio of 1.6:1, and the detection indicators of the mixed liquor are as follows.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com