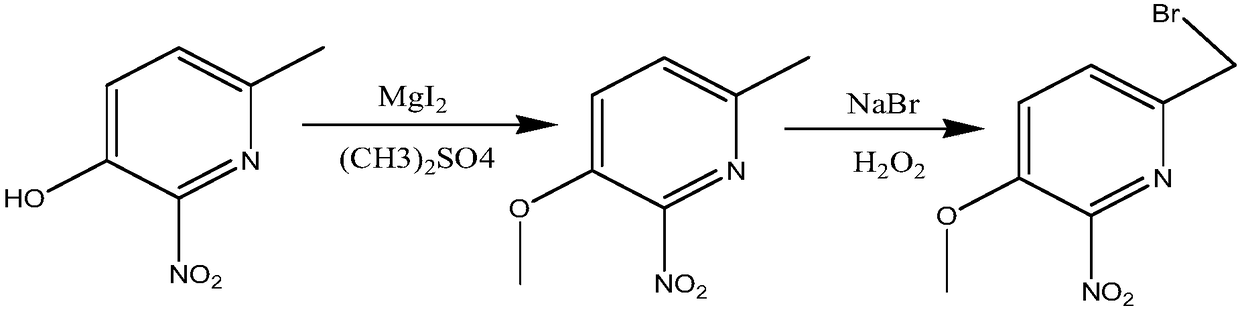

Method for synthesizing 6-bromomethyl-3-methoxy-2-nitropyridine

A technology of nitropyridine and methoxy, applied in the field of synthesizing 6-bromomethyl-3-methoxy-2-nitropyridine, which can solve the problems of difficult reaction temperature and difficult industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Add 15.4g of 6-methyl-3-hydroxy-2-nitropyridine, 16.5g of magnesium iodide and 100g of water into a 250mL four-necked bottle, heat the water bath to 75°C, add dropwise 14.5g of dimethyl sulfate to react 18 hours; add 200mL ethyl acetate for extraction, separate the water layer, evaporate the ethyl acetate, and recrystallize from ethanol to obtain 16.1 g of 6-methyl-3-methoxy-2-nitropyridine. Add 10.1g of 6-methyl-3-methoxy-2-nitropyridine, 10.3g of sodium bromide and 100mL of carbon tetrachloride into a 500mL four-necked bottle, heat to reflux, add 11g of hydrogen peroxide dropwise, and dropwise add Then continue to react for 36 hours; after the reaction, add 100mL of 1M sodium hydroxide solution, cool, add 200mL of ethyl acetate for extraction, and distill off the ethyl acetate to obtain a yellow oil; the yellow oil is separated by alumina column chromatography, and then 75 % acetonitrile aqueous solution to obtain 11.1 g of light yellow 6-bromomethyl-3-methoxy-2-nitro...

example 2

[0020] Add 15.4g of 6-methyl-3-hydroxy-2-nitropyridine, 16.5g of magnesium iodide and 100g of water into a 250mL four-necked bottle, heat the water bath to 75°C, add dropwise 14.5g of dimethyl sulfate to react 20 hours; add 200mL ethyl acetate for extraction, separate the water layer, evaporate the ethyl acetate, and recrystallize from ethanol to obtain 16.1 g of 6-methyl-3-methoxy-2-nitropyridine. Add 10.1g of 6-methyl-3-methoxy-2-nitropyridine, 10.3g of sodium bromide and 100mL of carbon tetrachloride into a 500mL four-necked bottle, heat to reflux, add 11g of hydrogen peroxide dropwise, and dropwise add Then continue to react for 40 hours; after the reaction, add 100mL of 1M sodium hydroxide solution, cool, add 200mL of ethyl acetate for extraction, and distill off the ethyl acetate to obtain a yellow oil; the yellow oil is separated by alumina column chromatography, and then 75 % acetonitrile aqueous solution to obtain 11.1 g of light yellow 6-bromomethyl-3-methoxy-2-nitro...

example 3

[0022] Add 15.4g of 6-methyl-3-hydroxy-2-nitropyridine, 16.5g of magnesium iodide and 100g of water into a 250mL four-necked bottle, heat the water bath to 75°C, add dropwise 14.5g of dimethyl sulfate to react 24 hours; add 200mL ethyl acetate for extraction, separate the water layer, evaporate the ethyl acetate, and recrystallize from ethanol to obtain 16.1 g of 6-methyl-3-methoxy-2-nitropyridine. Add 10.1g of 6-methyl-3-methoxy-2-nitropyridine, 10.3g of sodium bromide and 100mL of carbon tetrachloride into a 500mL four-necked bottle, heat to reflux, add 11g of hydrogen peroxide dropwise, and dropwise add Then continue to react for 48 hours; after the reaction, add 100mL of 1M sodium hydroxide solution, cool, add 200mL of ethyl acetate for extraction, evaporate the ethyl acetate to obtain a yellow oil; the yellow oil is separated by alumina column chromatography, and then 75 % acetonitrile aqueous solution to obtain 11.1 g of light yellow 6-bromomethyl-3-methoxy-2-nitropyridi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com