Electrochemical dyeing device and method using yarn dyeing roller as cathode

A yarn dyeing and dyeing device technology, which is applied in dyeing methods, textile material processing, textiles and papermaking, etc., can solve the problems of lack of color fixing devices and unfavorable actual production, etc., so as to improve dyeing efficiency, structure and save resources. Reduce the effect of the stirring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

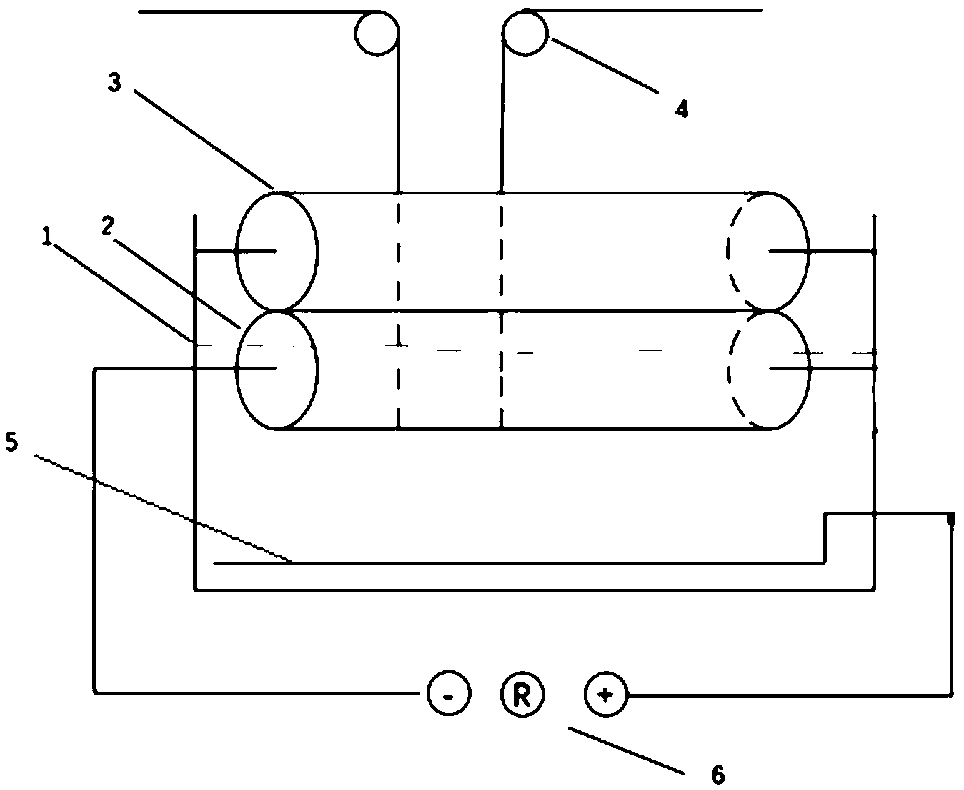

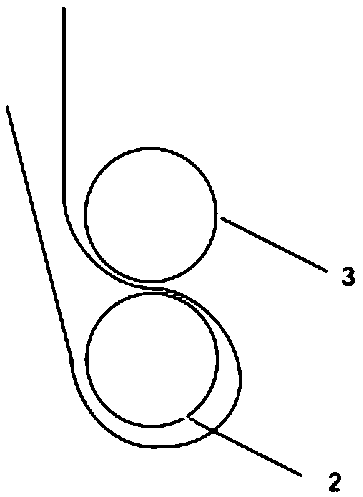

[0028] A method for dyeing using the above-mentioned electrochemical dyeing device with the yarn dyeing roller as the cathode, which includes the following steps:

[0029] The dye liquor in the dye tank includes the following concentrations of solutes: 0.2mol / L sodium hydroxide, 0.01mol / L iron sulfate, 0.1mol / L triethanolamine, 0.02mol / L vat yellow;

[0030] The anode 5 and the cathode yarn dyeing roller 2 are respectively connected to the positive and negative electrodes of the DC power supply 6, and the current density is controlled to be 0.08-0.1 ampere / square decimeter, and the yarn is wound on the The cathodic yarn dyeing roller 2 is contacted with the dye solution for dyeing, and then the tension adjustment and heat-fixing treatment are carried out through the resistance heating roller 3. The working temperature of the resistance heating roller 3 is controlled at 80-85° C. The yarn roller 4 is connected to the winding device after changing direction, and finally the K / S ...

Embodiment 2

[0032] A method for dyeing using the above-mentioned electrochemical dyeing device with the yarn dyeing roller as the cathode, which includes the following steps:

[0033] The dye solution in the dye tank includes the following concentrations of solutes: 0.1mol / L sodium hydroxide, 0.1mol / L ferric chloride, 0.5mol / L triethanolamine, 0.01mol / L vat red;

[0034] The anode 5 and the cathode yarn dyeing roller 2 are respectively connected to the positive and negative poles of the DC power supply 6, and the current density is controlled to be 0.2-0.5 ampere / square decimeter, and the yarn is wound on the The cathodic yarn dyeing roller 2 is contacted with the dye solution for dyeing, and then the tension adjustment and heat-fixing treatment are carried out through the resistance heating roller 3. The working temperature of the resistance heating roller 3 is controlled at 90-95°C, and finally another guide The yarn roller 4 is connected to the winding device after changing direction, ...

Embodiment 3

[0036] A method for dyeing using the above-mentioned electrochemical dyeing device with the yarn dyeing roller as the cathode, which includes the following steps:

[0037] The dye liquor in the dye tank includes the following concentrations of solutes: 0.1-0.2mol / L sodium hydroxide, 0.5-1mol / L iron sulfate, 1.5-2mol / L triethanolamine, 0.05-0.1mol / L vat green;

[0038] The anode 5 and the cathode yarn dyeing roller 2 are respectively connected to the positive and negative poles of the DC power supply 6, and the current density is controlled to be 0.8-1.2 ampere / square decimeter, and the yarn is wound on the The cathodic yarn dyeing roller 2 is contacted with the dye solution for dyeing, and then the tension adjustment and heat-fixing treatment are carried out through the resistance heating roller 3. The working temperature of the resistance heating roller 3 is controlled at 95-100° C. The yarn roller 4 is connected to the winding device after changing direction, and finally the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com