Preparation method of special long-acting anti-mite agent for natural fiber fabrics

A technology of natural fiber and anti-mite agent, applied in the direction of natural fiber, fiber treatment, biochemical fiber treatment, etc., can solve the problems of insufficient mite removal effect and short anti-mite period, and achieve long-term effective maintenance of mite-proof effect and avoid loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

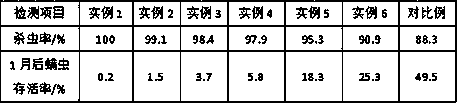

Examples

example 1

[0023]Pour the sepiolite into the pulverizer, and pass through a 180-mesh sieve after crushing to obtain sepiolite powder, then mix the obtained sepiolite powder and hydrochloric acid with a mass fraction of 12% into the No. 1 beaker at a mass ratio of 1:12 , and move the No. 1 beaker into a digital display speed measuring constant temperature magnetic stirrer, under the condition of temperature of 50°C and rotation speed of 600r / min, after constant temperature stirring and reaction for 3 hours, filter to obtain a filter cake, and wash the filter cake with deionized water for 5 times , and then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain a dry filter cake, and then transfer the obtained dry filter cake to a tube furnace, and dry it at a temperature of 280°C , after heat preservation and roasting for 4 hours, cool to room temperature with the furnace, and discharge to obtain modified sepiolite; in parts by weigh...

example 2

[0025] Pour the sepiolite into the pulverizer, and pass through a 180-mesh sieve after crushing to obtain sepiolite powder, then mix the obtained sepiolite powder and hydrochloric acid with a mass fraction of 12% into the No. 1 beaker at a mass ratio of 1:12 , and move the No. 1 beaker into a digital display speed measuring constant temperature magnetic stirrer, under the condition of temperature of 50°C and rotation speed of 600r / min, after constant temperature stirring and reaction for 3 hours, filter to obtain a filter cake, and wash the filter cake with deionized water for 5 times , and then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain a dry filter cake, and then transfer the obtained dry filter cake to a tube furnace, and dry it at a temperature of 280°C , after heat preservation and roasting for 4 hours, cool to room temperature with the furnace, and discharge to obtain modified sepiolite; in parts by weig...

example 3

[0027] Pour the sepiolite into the pulverizer, and pass through a 180-mesh sieve after crushing to obtain sepiolite powder, then mix the obtained sepiolite powder and hydrochloric acid with a mass fraction of 12% into the No. 1 beaker at a mass ratio of 1:12 , and move the No. 1 beaker into a digital display speed measuring constant temperature magnetic stirrer, under the condition of temperature of 50°C and rotation speed of 600r / min, after constant temperature stirring and reaction for 3 hours, filter to obtain a filter cake, and wash the filter cake with deionized water for 5 times , and then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain a dry filter cake, and then transfer the obtained dry filter cake to a tube furnace, and dry it at a temperature of 280°C , after heat preservation and roasting for 4 hours, cool to room temperature with the furnace, and discharge to obtain modified sepiolite; in parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com