A bog processing method for lng cars or ships

A treatment method and ship technology, applied in the direction of container discharge, fluid treatment, container filling method, etc., can solve the problems of natural gas accumulation, hidden dangers of safety accidents, etc., and achieve the effects of protecting the environment, reducing pollution, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

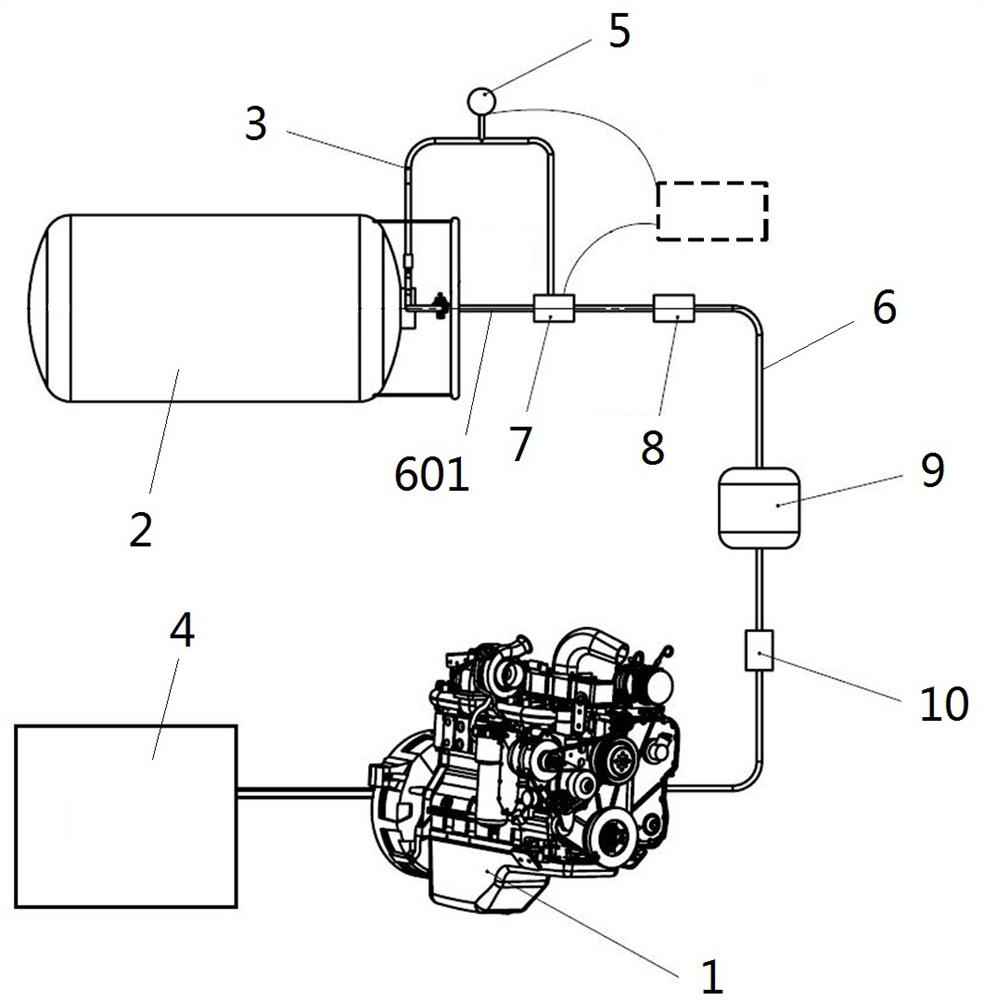

[0028] A kind of BOG processing method of LNG automobile or ship of the present invention, such as figure 1 shown, including the following steps:

[0029] When the engine 1 is in the off state and the pressure value in the LNG storage tank 2 exceeds the first set value, the control module sends an instruction to connect the gas phase end passage 3 of the LNG storage tank 2, so that the BOG gas in the LNG storage tank 2 can enter Engine 1, at the same time close the passage of liquid-phase natural gas entering the engine; and the control module sends an instruction to start the engine 1, the engine 1 enters an idle state, and charges the battery pack 4 by consuming BOG gas;

[0030] The BOG gas is continuously consumed until the pressure in the LNG storage tank 2 is lower than the second set value, and the control module sends an instruction to shut down the engine 1 .

[0031] Wherein, the overcharge protection is activated after the battery pack 4 is fully charged, and the e...

Embodiment 2

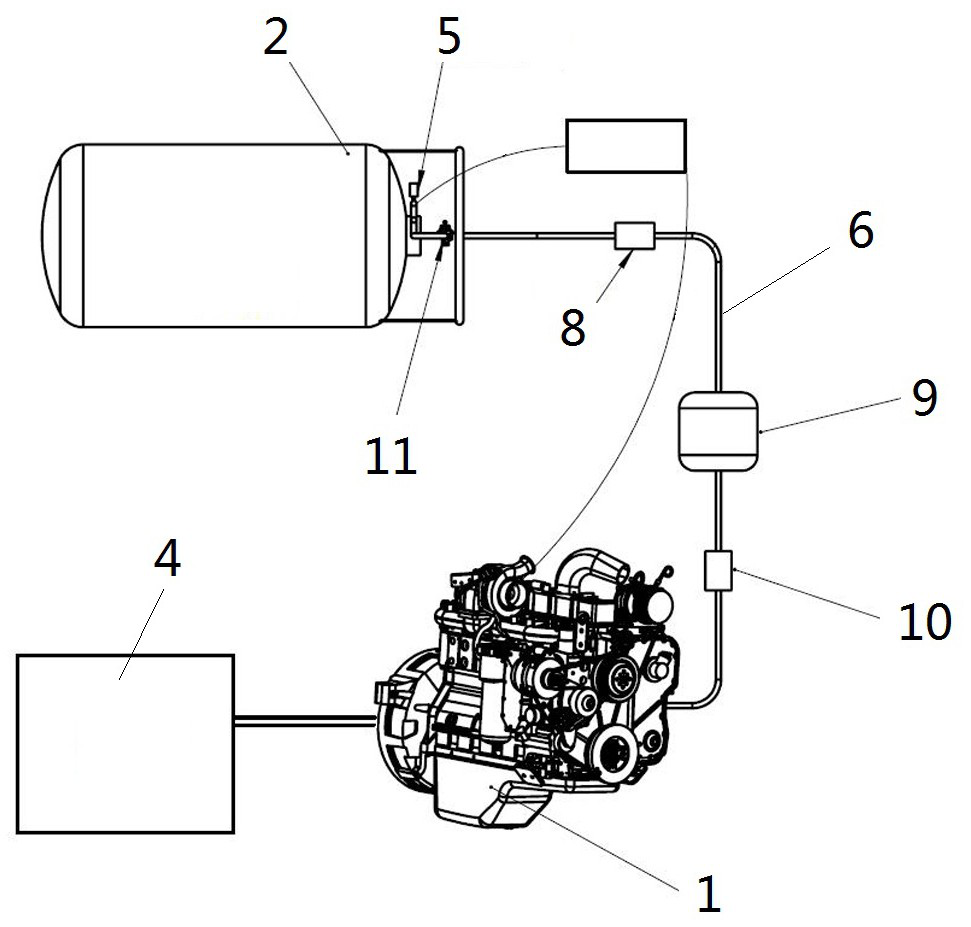

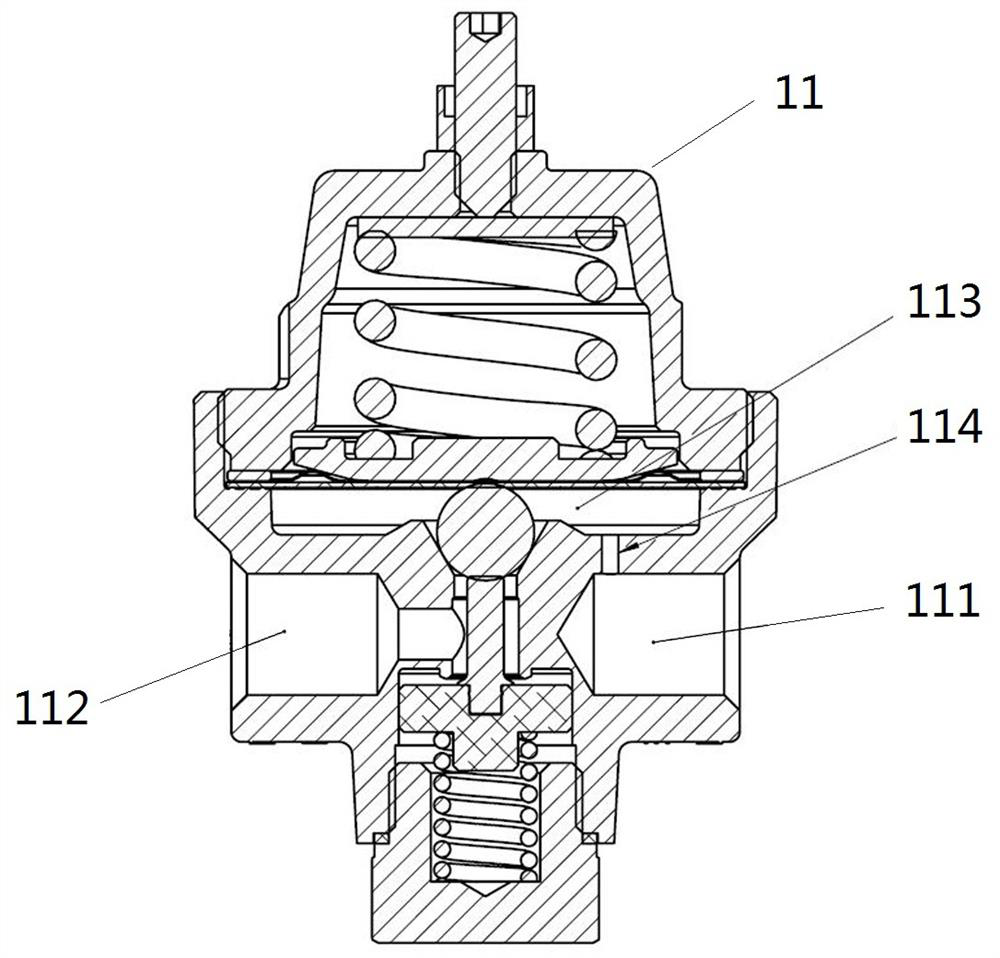

[0047] The invention also discloses a BOG processing system for LNG vehicles or ships, such as figure 2 and image 3 As shown, it includes the LNG storage tank 2, the main passage 6, the engine 1 and the battery pack 4, and also includes the pressure sensor 5 arranged at the gas phase outlet or channel of the LNG storage tank 2, and the mechanical pressure sensor arranged on the main passage 6. Type reversing valve 11, the mechanical pressure sensing reversing valve 11 is respectively connected with the gas phase channel and the liquid phase channel of the LNG storage tank 2 and shifts between them; The reversing valve 11 is connected with the LNG storage tank 2 , and the other end is connected with the engine 1 , and the engine 1 is connected with the battery pack 4 . A pressure-stabilizing valve 8 , a buffer tank 9 and a solenoid valve 10 are sequentially provided between the mechanical pressure-sensing reversing valve 11 and the engine 1 ; the pressure sensor 5 and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com