Preparation method of granular fermented dairy product allowing long-term normal temperature preservation

A technology for fermented dairy products and storage at room temperature, applied to dairy products, other dairy products, bacteria used in food preparation, etc., can solve the problems of short storage time and difficulty in storage at room temperature, and achieve the effect of ensuring sterility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

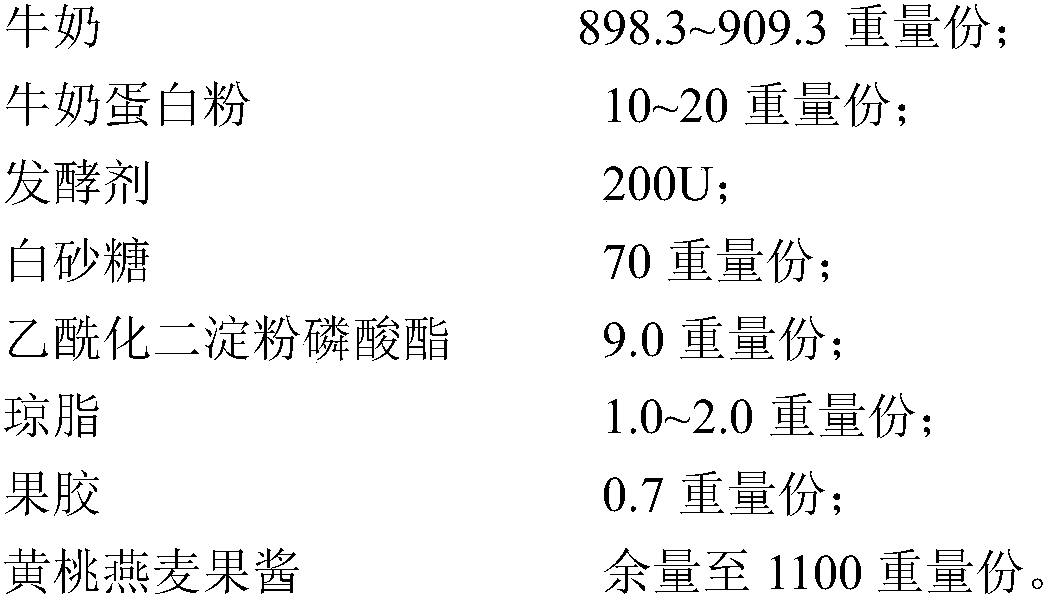

[0046] A normal temperature granular yoghurt, which has the following raw material composition (based on 1100 parts by weight of raw material):

[0047]

[0048] Raw material standard:

[0049] Milk: conform to GB19301-2010 standard;

[0050] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0051] The above-mentioned normal temperature granular yoghurt is prepared through the following steps:

[0052] 1. Homogeneous mixing: Physically sterilize the raw milk (milk) with a temperature not exceeding 8°C through a centrifugal sterilizer (two BB centrifuges in series) (temperature is 55-65°C, speed is 4500- 7500 rpm), heat the above sterilized raw milk to 50-55°C, mix it with milk protein powder, white sugar, stabilizer (acetylated distarch phosphate, agar, pectin) under high-speed stirring for 15-20 Minutes, the feed liquid is fully homogenized, the homogenization temperature is 55-75°C, and the pressure is 160-200bar / 30-...

Embodiment 2

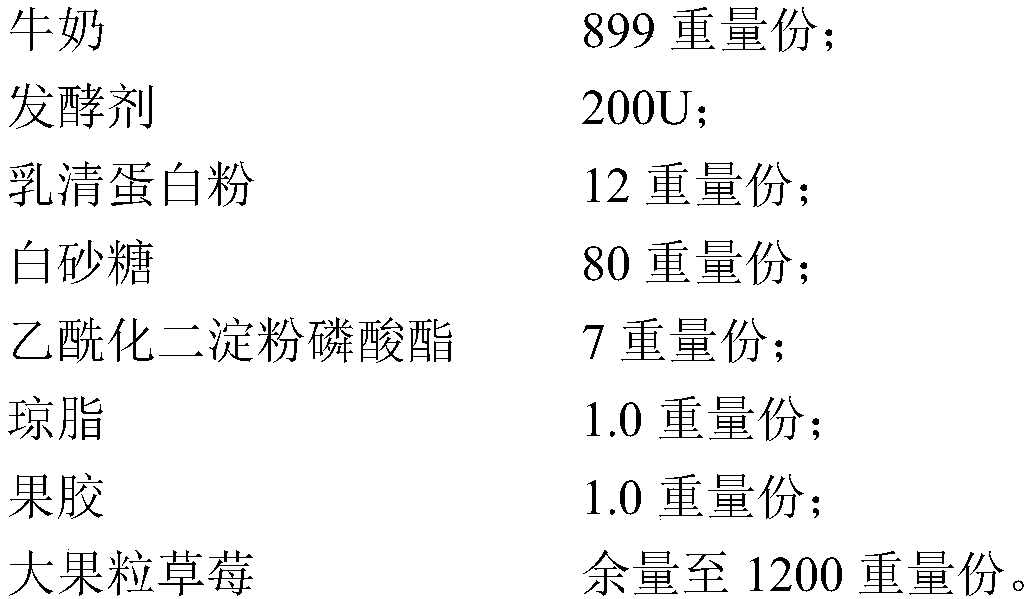

[0062] A normal temperature granular yogurt, which has the following raw material composition (based on 1200 parts by weight of raw material):

[0063]

[0064] Raw material standard:

[0065] Milk: conform to GB19301-2010 standard;

[0066] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0067] The above-mentioned normal temperature granular yoghurt is prepared through the following steps:

[0068] 1. Homogeneous mixing: Physically sterilize the raw milk (milk) with a temperature not exceeding 8°C through a centrifugal sterilizer (two BB centrifuges in series) (temperature is 55-65°C, speed is 4500- 7500 rpm), heat the above-mentioned sterilized raw milk to 50-55°C, mix it with whey protein powder, white sugar, stabilizer (acetylated distarch phosphate, agar, pectin) under high-speed stirring for 15 ~20 minutes, the material liquid is fully homogenized, the homogenization temperature is 55~75°C, and the pressure is ...

Embodiment 3

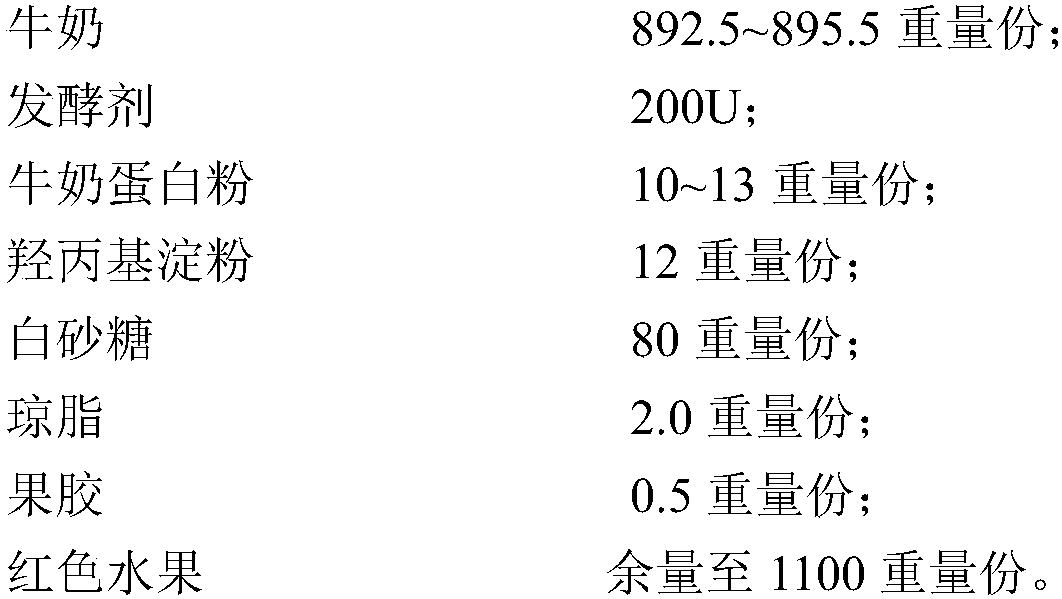

[0078] A normal temperature granular yoghurt, which has the following raw material composition (based on 1100 parts by weight of raw material):

[0079]

[0080] Among them, the red fruit is one or a mixture of strawberries, blueberries, red currants, purple carrots, sunflower seeds, pumpkin seeds, and flaxseeds.

[0081] Raw material standard:

[0082]Milk: conform to GB19301-2010 standard;

[0083] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0084] The above-mentioned normal temperature granular yoghurt is prepared through the following steps:

[0085] 1. Homogeneous mixing: Physically sterilize the raw milk (milk) with a temperature not exceeding 8°C through a centrifugal sterilizer (two BB centrifuges in series) (temperature is 55-65°C, speed is 4500- 7500 rpm), heat the sterilized raw milk to 50-55°C, mix it with milk protein powder, white sugar, stabilizer (hydroxypropyl starch, agar, pectin) under high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com