Oil-gas-water three-phase hydrogen sulfide absorbent and preparation method thereof

A hydrogen sulfide, oil-gas-water technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of incomplete hydrogen sulfide reaction and low desulfurization efficiency, achieve good complexation and adsorption capacity, and improve desulfurization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

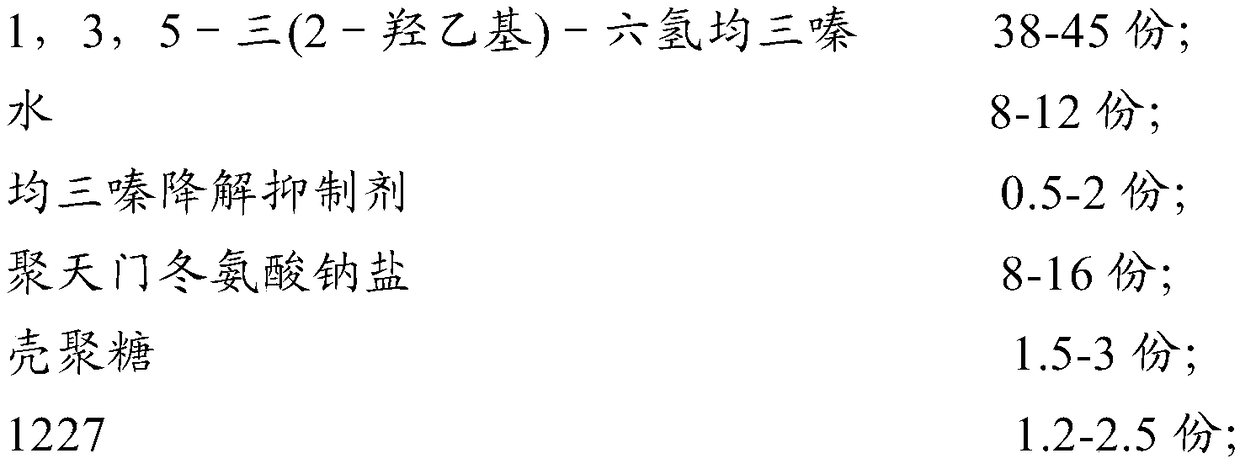

Method used

Image

Examples

Embodiment 1

[0020] Add 80g of water, 12g of 1227, 80g of methanol, 90g of isopropanol, 1g of Span-85 into the mixing tank, and stir for half an hour; add 15g of chitosan and stir for half an hour; add 80g of polyaspartic acid sodium salt, and stir for 20 minutes; add 5g of s-triazine degradation inhibitor ethoxylated isotridecanol and stir for 10 minutes; add 380g of 1,3,5-tris(2-hydroxyethyl)-hexahydro-s-triazine, dissolve it completely and add to In the reaction kettle, heat to 30°C, stir and keep warm for 4 hours to obtain the finished oil-gas-water three-phase hydrogen sulfide absorbent.

Embodiment 2

[0022] Add 120g of water, 25g of 1227, 110g of methanol, 130g of isopropanol, 3g of Span-85 into the stirring tank, and stir for half an hour; add 30g of chitosan and stir for half an hour; add 160g of polyaspartic acid sodium salt, and stir for 20 minutes; add 20g of s-triazine degradation inhibitor ethoxylated isotridecanol and stir for 10 minutes; add 450g of 1,3,5-tris(2-hydroxyethyl)-hexahydro-s-triazine, dissolve it completely and add to In the reaction kettle, heat to 30°C, stir and keep warm for 4 hours to obtain the finished oil-gas-water three-phase hydrogen sulfide absorbent.

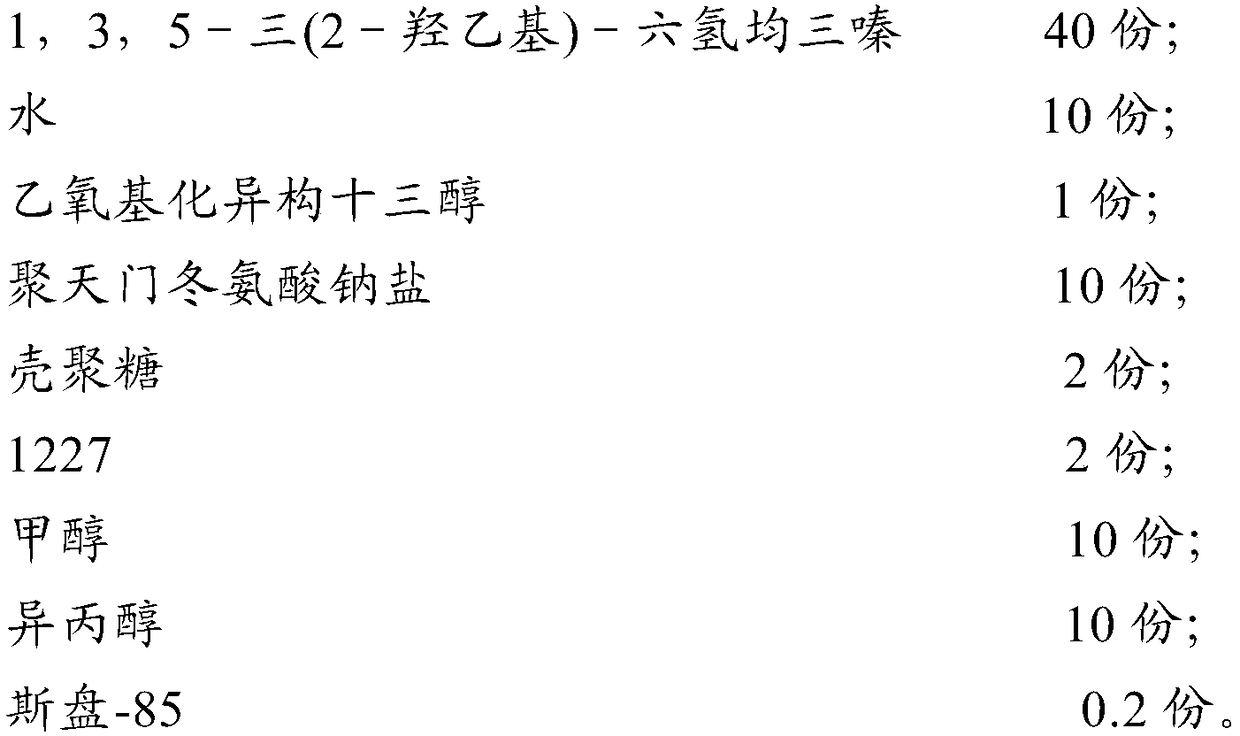

Embodiment 3

[0024] Add 100g of water, 20g of 1227, 100g of methanol, 100g of isopropanol, 2g of Span-85 into the stirring tank, and stir for half an hour; add 20g of chitosan and stir for half an hour; add 100g of polyaspartic acid sodium salt, and stir for 20 minutes; add 10g of s-triazine degradation inhibitor ethoxylated isotridecanol and stir for 10 minutes; add 400g of 1,3,5-tris(2-hydroxyethyl)-hexahydro-s-triazine, dissolve completely and add to In the reaction kettle, heat to 30°C, stir and keep warm for 4 hours to obtain the finished oil-gas-water three-phase hydrogen sulfide absorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com