Stabilization repairing agent for soil pollution and preparation and application

A soil pollution and remediation agent technology, which is applied in the field of stable remediation of contaminated soil, can solve the problems of soil reduction, high price, secondary pollution, etc., and achieve the effect of wide material sources, simple application methods, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

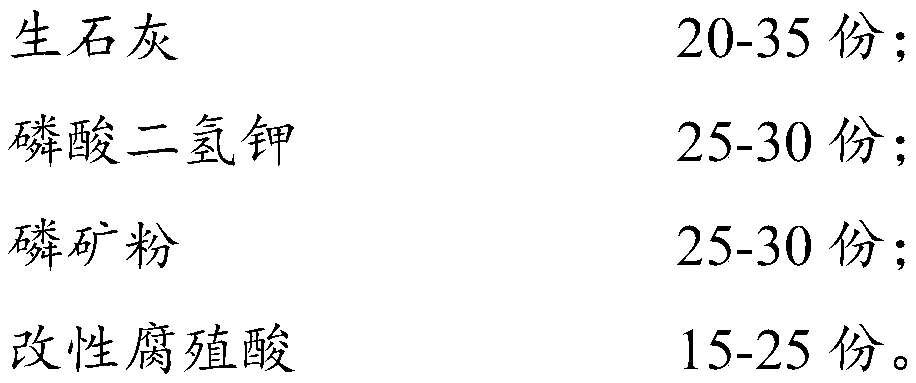

Method used

Image

Examples

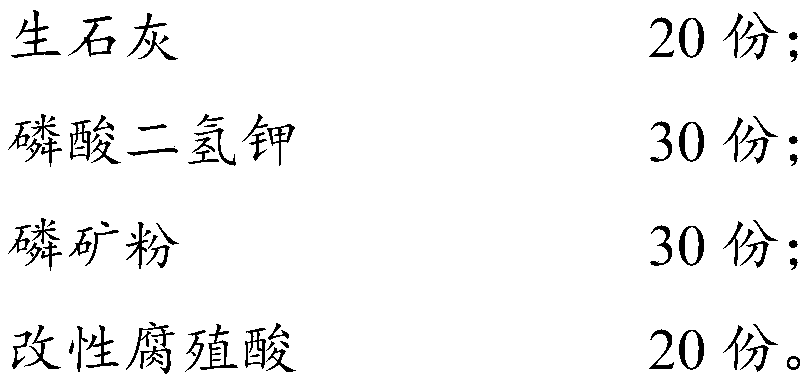

Embodiment 1

[0040] (1) Preparation of modified humic acid

[0041] S1: Under the condition of 26°C, mix humic acid and 1mol / L HCl according to the mass-volume ratio of 0.1g / mL for 24 hours, and then centrifuge to remove the supernatant after standing still to obtain primary-washed humic acid.

[0042] S2: Under the condition of 26°C, use 0.1mol / L HCl to wash the initial washing humic acid again, mix the initial washing humic acid and 0.1mol / L HCl according to the mass volume ratio of 0.1g / mL, and the mixing reaction time is 5min , remove the supernatant to obtain the secondary HCl pickling humic acid.

[0043] S3: Mix 1 mol / L HCl and 20 mol / L HF according to the volume ratio of 1:1 to obtain HCl / HF mixed solution; the secondary HCl pickling humic acid and HCl / HF mixed solution obtained in S2 are mixed according to the mass Mix with a volume ratio of 0.5g / mL to decompose the residual inorganic matter in the humic acid pickling with HCl twice, the temperature condition is 60°C, the reactio...

Embodiment 2

[0052] (1) Preparation of modified humic acid

[0053] S1: Mix humic acid and 2mol / L HCl at a mass-volume ratio of 0.125g / mL at 30°C, react for 20 hours, and centrifuge to remove the supernatant after standing still to obtain primary-washed humic acid.

[0054] S2: Under the condition of reaction temperature of 20°C, use 0.2mol / L HCl to wash the initial washing humic acid again, mix the initial washing humic acid and 0.2mol / L HCl according to the mass volume ratio of 0.125g / mL, and mix the reaction The time is 10 minutes, and the supernatant is removed to obtain the secondary HCl pickling humic acid.

[0055] S3: Mix 2mol / L HCl and 10mol / L HF according to the volume ratio of 1:1 to obtain the HCl / HF mixture; the secondary HCl pickling humic acid and HCl / HF mixture obtained in S2 are mixed according to the mass Mix with a volume ratio of 0.25g / mL to decompose the residual inorganic substances in the secondary HCl pickling humic acid. The temperature condition is 65°C and the r...

Embodiment 3

[0064] (1) Preparation of modified humic acid

[0065] S1: At 20°C, mix humic acid and 1.5 mol / L HCl at a mass volume ratio of 0.083 g / mL, mix and react for 30 hours, and centrifuge to remove the supernatant after standing still to obtain primary-washed humic acid.

[0066] S2: Under the condition of reaction temperature of 30°C, use 0.15mol / L HCl to wash the initial washing humic acid again, mix the initial washing humic acid and 0.15mol / L HCl according to the mass volume ratio of 0.083g / mL, and mix the reaction The time is 2 minutes, and the supernatant is removed to obtain humic acid washed with HCl twice.

[0067] S3: Mix 1.5mol / L HCl and 15mol / L HF according to the volume ratio of 1:2 to obtain the HCl / HF mixed solution; the secondary HCl pickling humic acid and HCl / HF mixed solution obtained in S2, according to The mass volume ratio is 0.33g / mL, and the residual inorganic substances in the humic acid pickling are decomposed twice. The temperature condition is 50°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com