Adsorbent for separating formaldehyde from air

An adsorbent and formaldehyde technology, applied in the field of air purification, can solve the problems of secondary pollution, short service life, low adsorption rate of harmful substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

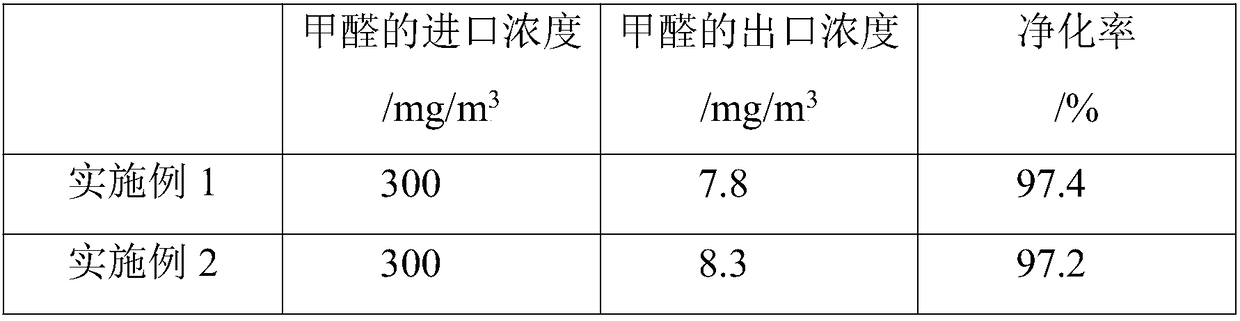

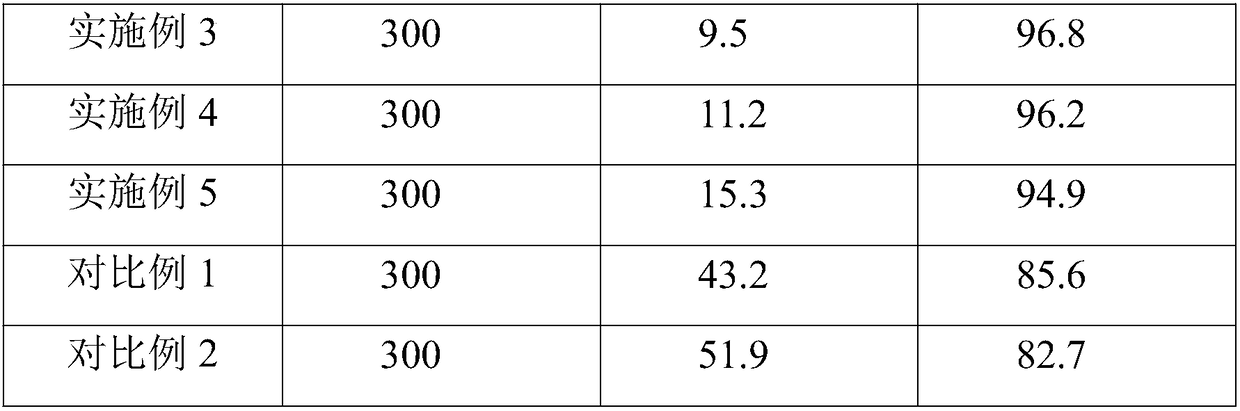

Examples

preparation example Construction

[0008] The present invention also provides a method for preparing the adsorbent for separating formaldehyde from air, comprising the following steps:

[0009] (1) Annealing the straw at 200-600°C for 5-12 hours in an inert gas atmosphere to obtain porous activated carbon;

[0010] (2) After mixing diatomite and maleic anhydride in water evenly, microwave reaction for 30-60 minutes to obtain modified diatomite;

[0011] (3) Stir and mix organic titanate, tin salt and ammonium carbonate in a solvent, then add porous activated carbon, CH 3 NH 3 I, silane coupling agent and modified diatomaceous earth are ultrasonically dispersed for 20-60 minutes, followed by sealed thermal reaction at 100-160°C for 2-6 hours to obtain an adsorbent for separating formaldehyde from air.

[0012] Straw is rich in pore structure and has a wide range of raw materials. After calcination, it can produce porous activated carbon with high specific surface area and high adsorption.

[0013] In order to...

Embodiment 1

[0020] An adsorbent for separating formaldehyde from the air, made of the following materials in parts by weight: 75 parts by weight of diatomite, 50 parts by weight of wheat straw, 8 parts by weight of maleic anhydride, 10 parts by weight of ammonium acetate, titanic acid 16 parts by weight of tetraisobutyl ester, 0.4 parts by weight of tin chloride, CH 3 NH 3 5 parts by weight of I, 4 parts by weight of ammonium carbonate, 4 parts by weight of divinyltriaminopropyltrimethoxysilane, and 100 parts by weight of water.

[0021] The preparation method of the adsorbent for separating formaldehyde from air may further comprise the steps:

[0022] (1) Anneal wheat straw at 300°C for 8 hours in an argon atmosphere to obtain porous activated carbon;

[0023] (2) Anneal diatomaceous earth at 350°C for 2 hours; then mix it with maleic anhydride and ammonium acetate in water, and react with microwave for 60 minutes, the frequency of the microwave reaction is 1200KHZ, and the power is 6...

Embodiment 2

[0026] An adsorbent for separating formaldehyde from air, made of the following materials in parts by weight: 80 parts by weight of diatomite, 40 parts by weight of wheat straw, 10 parts by weight of maleic anhydride, 8 parts by weight of ammonium acetate, titanic acid 12 parts by weight of tetramethyl ester, 0.4 parts by weight of tin chloride, CH 3 NH 3 3.2 parts by weight of I, 4 parts by weight of ammonium carbonate, 4.5 parts by weight of ureapropyltrimethoxysilane, and 100 parts by weight of water.

[0027] The preparation method of the adsorbent for separating formaldehyde from air may further comprise the steps:

[0028] (1) Anneal wheat straw at 400°C for 6 hours in an argon atmosphere to obtain porous activated carbon;

[0029] (2) Anneal diatomaceous earth at 300-500°C for 1-3 hours; then mix it with maleic anhydride and ammonium acetate in water, and react with microwave for 30-60 minutes. The frequency of the microwave reaction is 1000-1800KHZ, and the power 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com