Method for producing graphene from biological cathode through reduction and removing sulfate

A biocathode and sulfate technology, applied in the field of bioelectrochemical systems, can solve problems such as exchange membrane blockage, high energy consumption, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

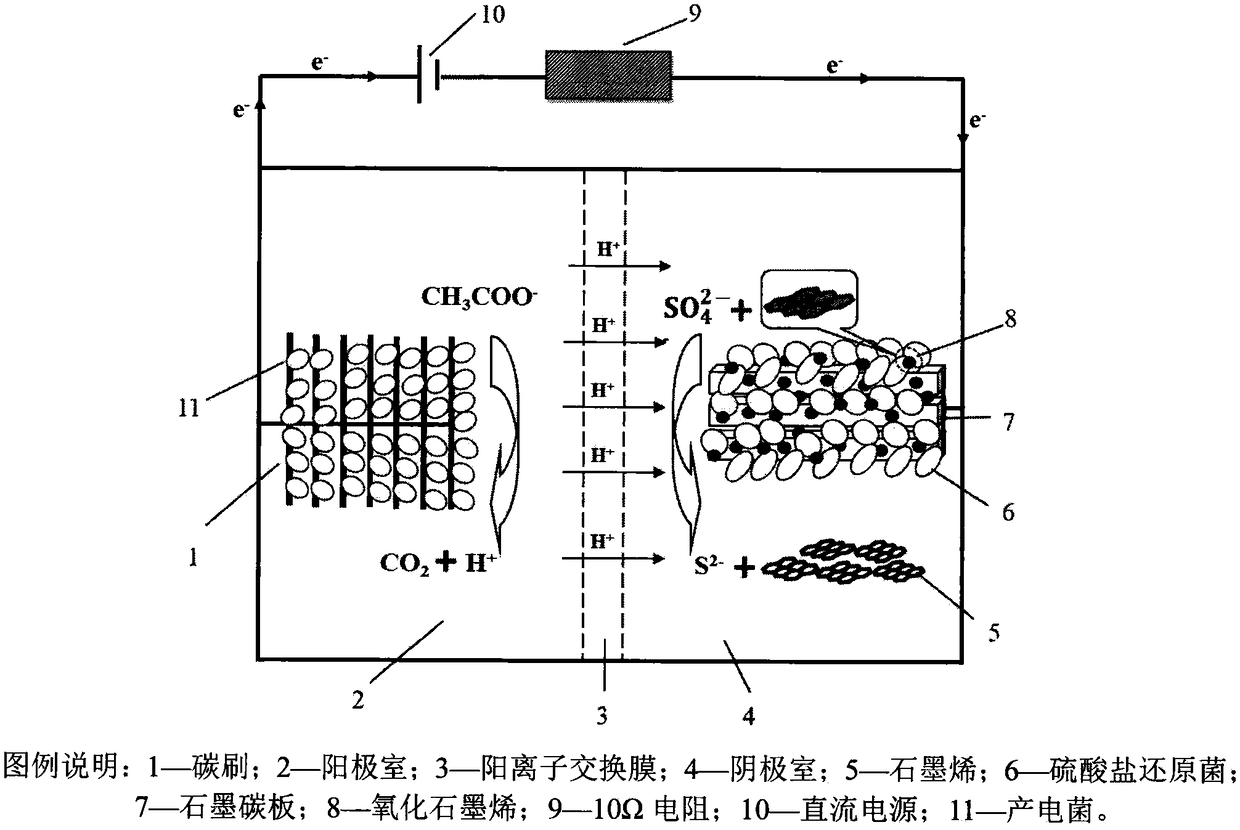

[0016] Bioelectrochemical system reduction production of graphene synergistically removes sulfate wastewater device uses 1g / L anhydrous sodium acetate as anolyte, the specific composition is (in 1L deionized water): 1g CH 3 COONa, 10.35g Na 2 HPO 4 12H 2 O, 3.31gNaH 2 PO 4 2H 2 O, 0.31g NH 4 Cl, 0.13g KCl, 12.5mL trace element solution and 12.5mL vitamin solution. The electrogenic bacteria in the anode chamber oxidize the organic matter to release electrons and protons, the electrons are transferred to the cathode through the external circuit, and the protons are transferred to the cathode chamber through the cation exchange membrane. Sulfate-reducing bacteria on the autotrophic cathode 2 or NaHCO 3 As an inorganic carbon source, graphene oxide, As an electron acceptor for reduction reaction, the whole process does not need to add an organic electron donor, and the artificially prepared sulfate wastewater is (in 1L deionized water): 720mg / L Na 2 SO 4 , inorganic sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com