Method for preparing high-content 1,3-bis(isocyanatomethyl)benzene

A technology for iso-xylylene isocyanate and meta-xylylene amine is applied in the field of preparing high-content iso-xylylene isocyanate, can solve problems such as inapplicability, and achieve shortened reaction time and production safety. The effect of high and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

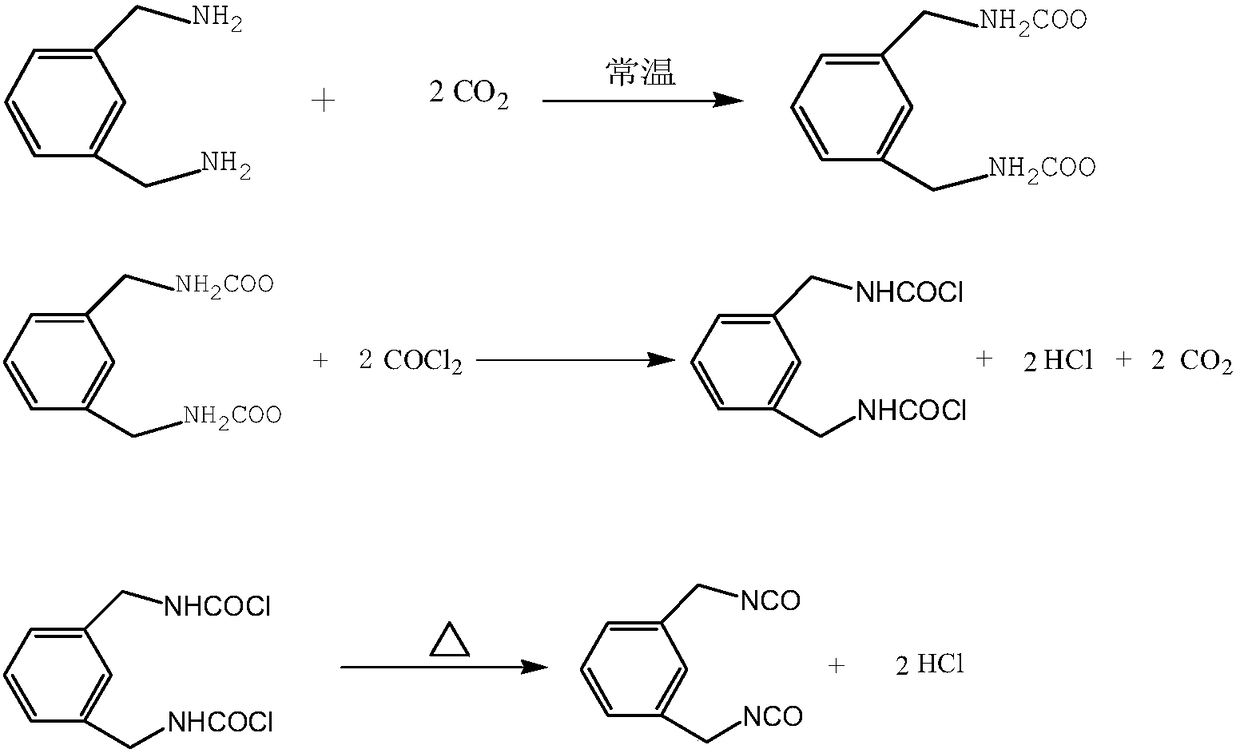

[0025] A. In a 50L reaction vessel with a Y-shaped reactor, circulation pump, cooler, heater, phosgene tail gas absorption processor, thermometer, pressure gauge and stirring, add 15L of o-dichlorobenzene, m-phthalylene Base amine 1500g. Turn on the circulating pump to circulate the o-dichlorobenzene of m-xylylene amine at a rate of 25L / min, and at the same time, pass in carbon dioxide at a rate of about 5L / min through another port of the Y-shaped reactor for 5 hours Afterwards, the measured pH value was 6. End with carbon dioxide. The temperature was raised to 60°C. Begin to flow phosgene at a speed of 2500ml / min, and gradually raise the temperature to 125°C, and flow back phosgene to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com