Preparation method of oily antirust demolding agent

A release agent, oil-based technology, applied in the field of release agent composition preparation, can solve the problems of steel plate corrosion, loss, etc., achieve the effect of improving anti-rust performance, suppressing metal ion concentration, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

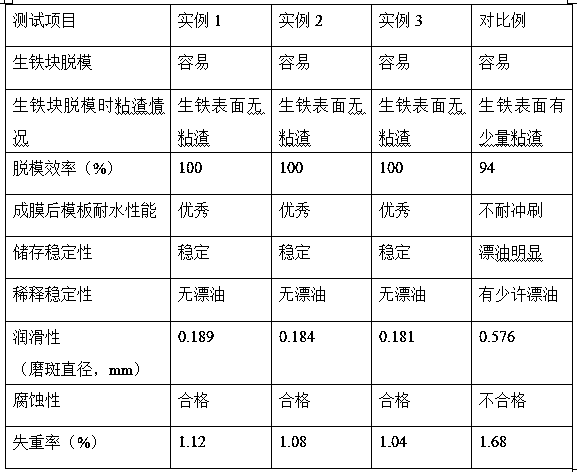

Examples

Embodiment Construction

[0029] Take 200-250g ginkgo seed kernels and put them into a refiner for 30-40min to obtain a seed kernel slurry, put the seed kernel slurry into a conical flask, add 40-50mL to the conical flask with a mass fraction of 15 % sodium chloride solution, 4-6g cellulase and 200-220mL distilled water, after enzymolysis for 40-45min, place the Erlenmeyer flask in a water bath, heat up to 80-90°C, and stir for 40-50min. Suction filtration, remove the filter residue and collect the seed kernel extract; place the seed kernel extract in an ultrasonic oscillator, and ultrasonically treat it at a frequency of 25~30kHz at 50~60°C for 40~45min to obtain an ultrasonic treatment liquid, and ultrasonically treat it The liquid is placed in a high-speed centrifuge at a speed of 2000-2500r / min, centrifuged for 15-20min, the lower layer of water is removed, and the upper layer of oil is collected as ginkgo oil; put 60-70mL of aniline and 50-55mL of absolute ethanol into the Put it into a three-neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com