Method for detecting holdup of split phases in oil sludge based on induction heating technique and system

A technology of induction heating and detection method, which is applied in the investigation phase/state change and other directions, which can solve the problems of long process, complex facilities, and inability to meet rapid detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the description of the present invention clear, the implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

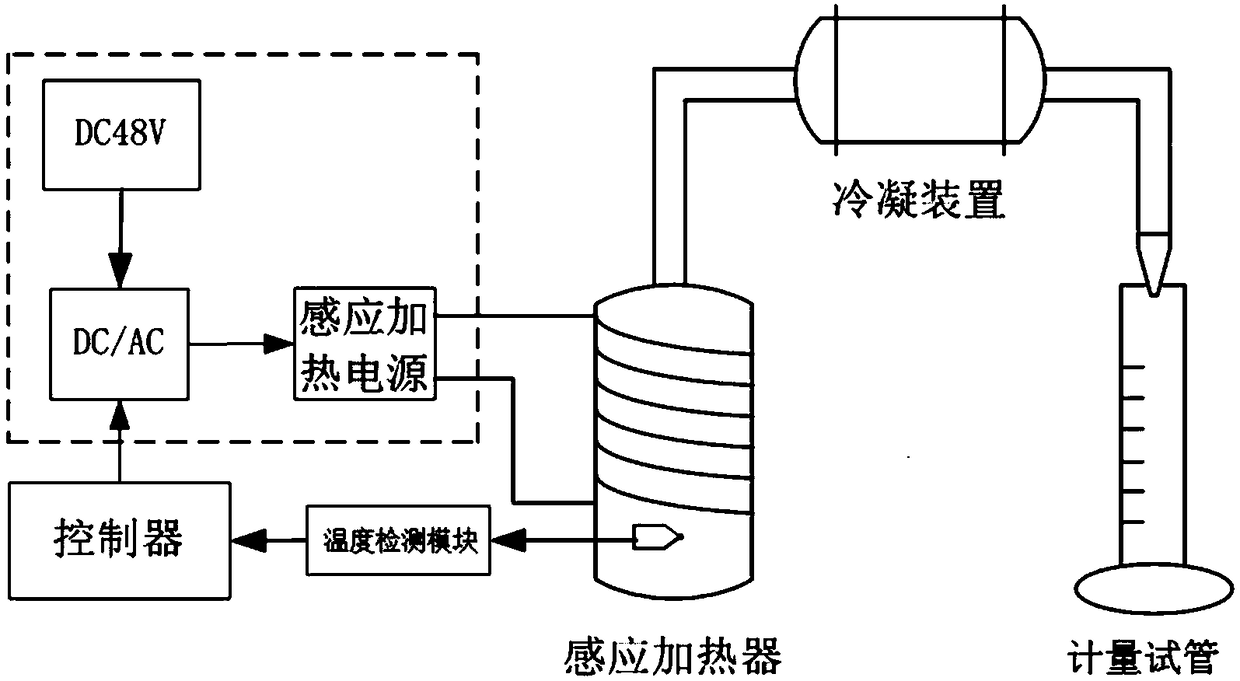

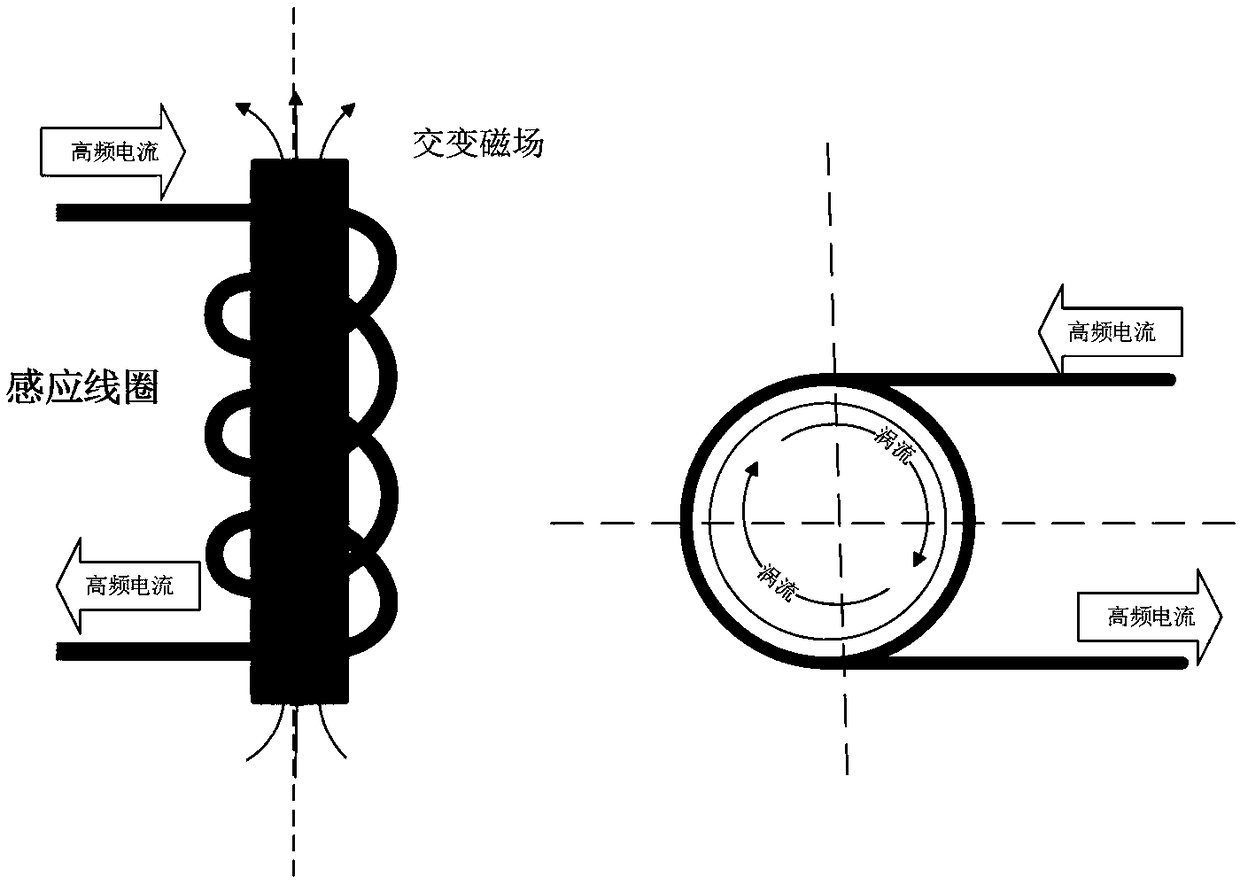

[0060] Such as Figure 5 As shown, the oil sludge phase separation content detection system based on the pyrolysis method mainly consists of an induction heating power supply, an induction heater, a temperature detection module, a controller, a condensation device, a measuring tube and an analytical balance. The DC 48V power supply is converted into a low-voltage and high-frequency induction heating power supply through inverter (DC / AC). The induction heater is used to place the container with pyrolysis sludge, specifically a copper crucible. Under the action of the induction heating power supply, an eddy current is generated in the hot copper crucible to heat up the oil sludge; the temperature detection module detects the temperature of the sludge sample in the induction h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com