Spongy C-SiC composite material and preparation method thereof

A composite material and sponge-like technology, which is applied in the field of sea sponge-like C-SiC composite material and its preparation, can solve problems such as a large amount of power consumption, and achieve the effects of improving electrical conductivity, shortening transmission distance and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

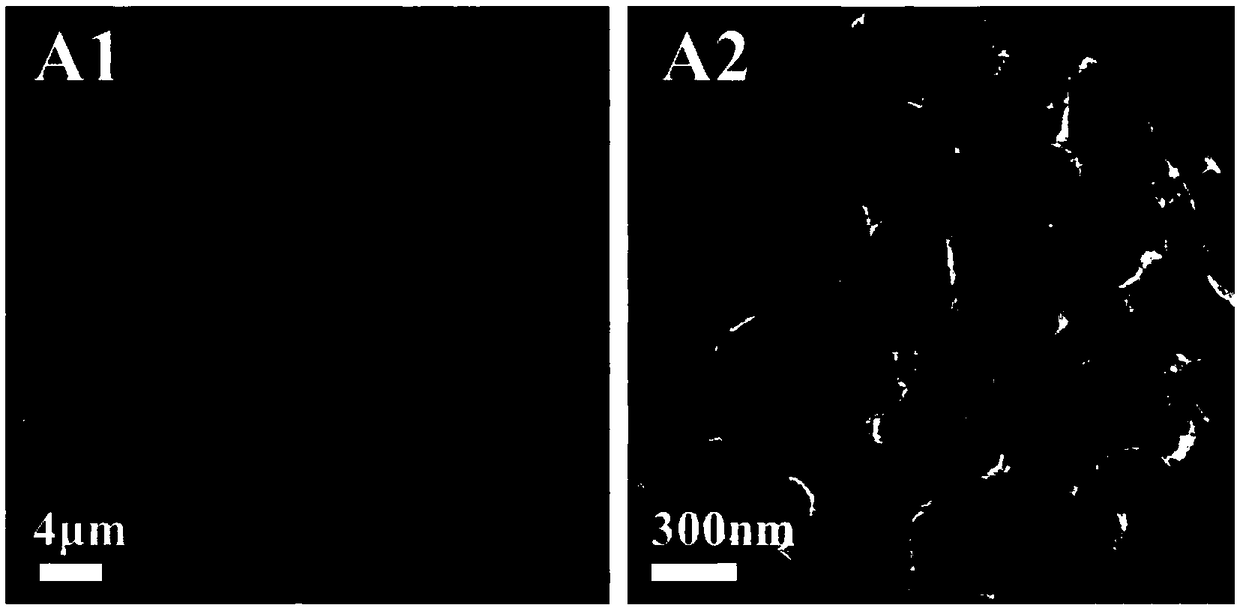

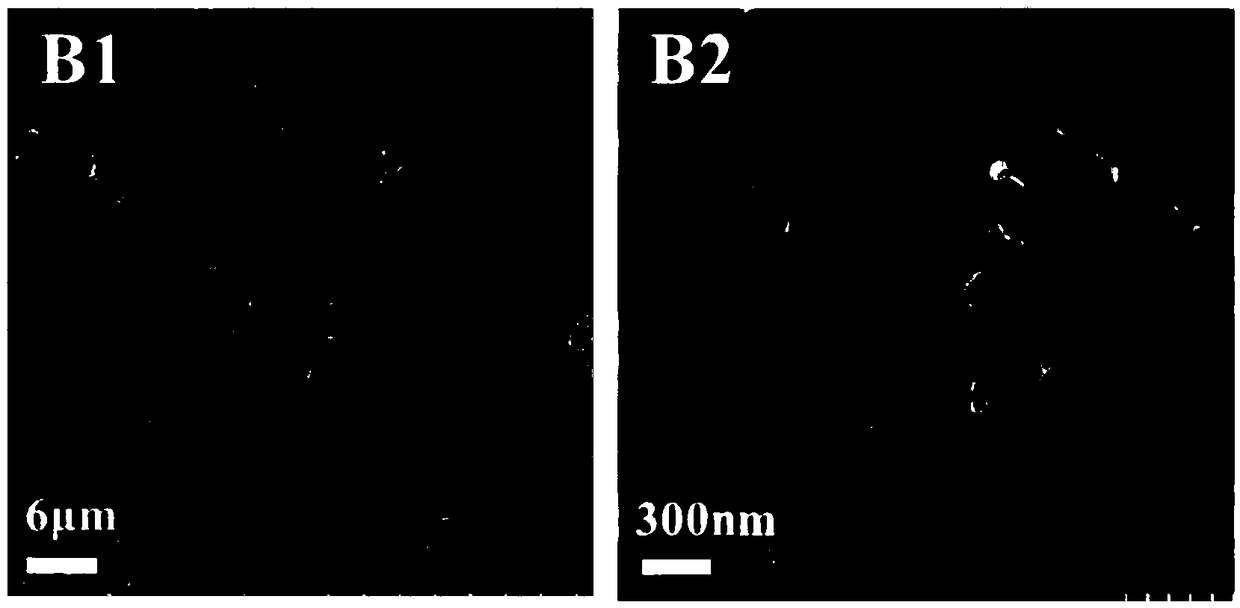

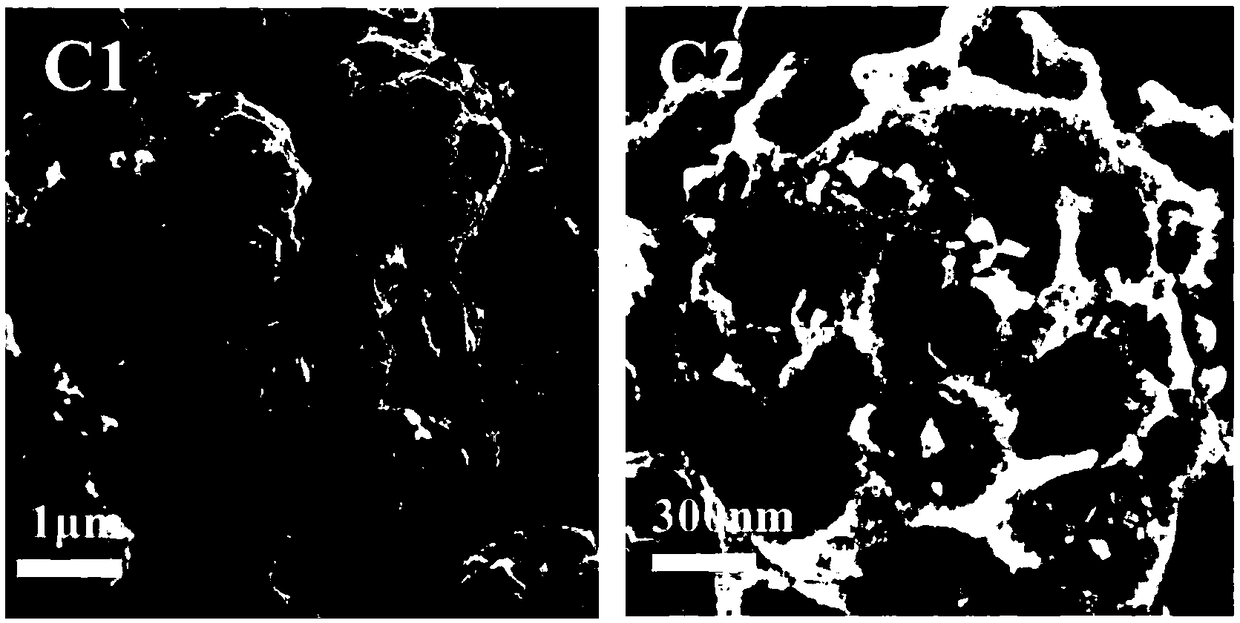

Image

Examples

Embodiment 1

[0064] This embodiment provides a method for preparing a sea-sponge C-SiC composite material, comprising the following steps:

[0065] (0) Preparation of porous carbon spheres

[0066] (0.1) Weigh 19.68g of sodium chloroacetate and dissolve it in 130mL of deionized water to form a light yellow transparent solution, and add it to a humidifier;

[0067] (0.2) Turn on the tube furnace, when the temperature of the quartz tube of the tube furnace reaches 600°C, continuously feed 1.0L / min Ar gas into the humidifier, and introduce the mist into the quartz glass tube of the tube furnace;

[0068] (0.3) After the reaction, use 75% ethanol to collect the black solid in the quartz glass tube, centrifuge to collect the product, and vacuum dry to obtain carbon spheres with a porous structure.

[0069] (1) C-SiO 2 preparation of

[0070] (1.1) Weigh 25 mg of porous carbon spheres prepared in the above step (0), dissolve them in a total volume of 50 mL of aqueous ethanol (the volume ratio...

Embodiment 2

[0081] This embodiment provides a method for preparing a sea-sponge C-SiC composite material, comprising the following steps:

[0082] (0) Preparation of porous carbon spheres

[0083] (0.1) Take an appropriate amount of configured sodium chloroacetate solution with a concentration of 1.8mol / L and add it to the humidifier;

[0084] (0.2) First turn on the tube furnace and gradually increase the furnace temperature. When the temperature rises to 700°C, turn on the humidifier switch and use nitrogen as the carrier gas. The gas flow rate is controlled at 1.25L / min, and the atomized mist droplets are introduced into the in a quartz tube;

[0085] (0.3) After the reaction, the product was washed with 75% ethanol for 3 to 5 times, centrifuged and dried to obtain carbon spheres with a porous structure.

[0086] (1) C-SiO 2 material preparation

[0087] (1.1) Mix and disperse 25 mg of porous carbon spheres prepared in step (0) and 1 mL of 10 mM CTAB solution in a total volume of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com