Composite material capable of lowering releasing amount of crotonaldehyde in cigarette gas and preparing method and application thereof

A composite material and crotonaldehyde technology, applied in the field of tobacco, can solve problems such as short time, inability to effectively remove harmful substances, and complicated preparation process, and achieve the effects of improving irritation, increasing adsorption efficiency and capacity, and reducing crotonaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composite material for reducing the emission of crotonaldehyde in smoke in this embodiment includes the following raw materials in parts by weight: 1 g of amino polysaccharide quaternary ammonium salt, 1 g of polyvinylpyrrolidone with a molecular weight of 1000, and 10 g of silica-alumina molecular sieve.

[0019] The preparation method of the composite material that reduces the emission of crotonaldehyde in flue gas of the present embodiment: proceed as follows:

[0020] Add 1g of aminopolysaccharide quaternary ammonium salt and 1g of polyvinylpyrrolidone with a molecular weight of 1000 to 100g of water to form a uniform solution, then add 10g of silica-alumina molecular sieve, ultrasonicate for 15min, take it out and dry it to obtain a composite material product.

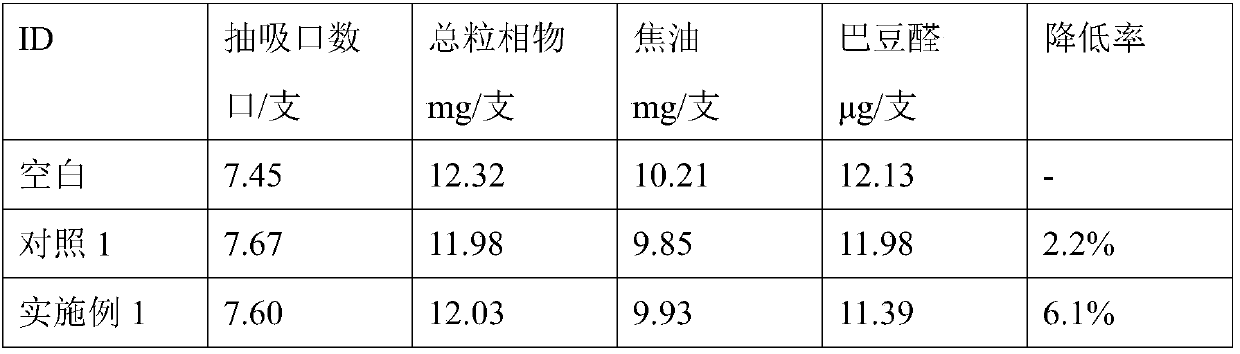

[0021] 50 mg of the above composite material was added to the cigarette tip rod. The prepared cigarettes were analyzed for smoke components, and the results are shown in Table 1, wherein the blank sampl...

Embodiment 2

[0025] The composite material for reducing the emission of crotonaldehyde in smoke in this embodiment includes the following raw materials in parts by weight: 10 g of organosilicon quaternary ammonium salt, 10 g of polyvinylpyrrolidone with a molecular weight of 1,000,000, and 1 g of phosphoraluminum molecular sieve.

[0026] The preparation method of the composite material that reduces the emission of crotonaldehyde in flue gas of the present embodiment: proceed as follows:

[0027] Add 10g of organosilicon quaternary ammonium salt and 10g of polyvinylpyrrolidone with a molecular weight of 1,000,000 to 100g of ethanol to form a uniform solution, then add 1g of phosphorus-aluminum molecular sieve, ultrasonicate for 10min, take it out and dry it, which is the required sieve composite material product.

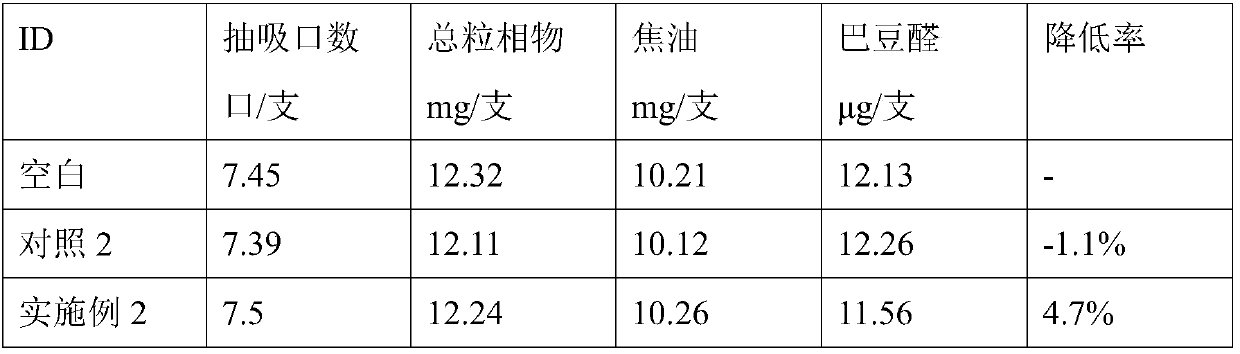

[0028] 10 mg of the molecular sieve composite was added to the cigarette tip rod. The prepared cigarettes were analyzed for smoke components, and the results are shown in Table...

Embodiment 3

[0032] The composite material for reducing the emission of crotonaldehyde in smoke in this embodiment includes the following raw materials in parts by weight: 2 g of double-chain sugar quaternary ammonium salt, 5 g of vinylpyrrolidone-maleic acid copolymer with a molecular weight of 100,000, and 5 g of clinoptilolite.

[0033] The preparation method of the composite material that reduces the emission of crotonaldehyde in flue gas of the present embodiment: proceed as follows:

[0034] Add 2g of double-chain sugar quaternary ammonium salt and 5g of vinylpyrrolidone-maleic acid copolymer with a molecular weight of 100,000 into 100g of water to form a homogeneous solution, then add 5g of clinoptilolite, ultrasonicate for 5min, take it out and dry it. required composite products.

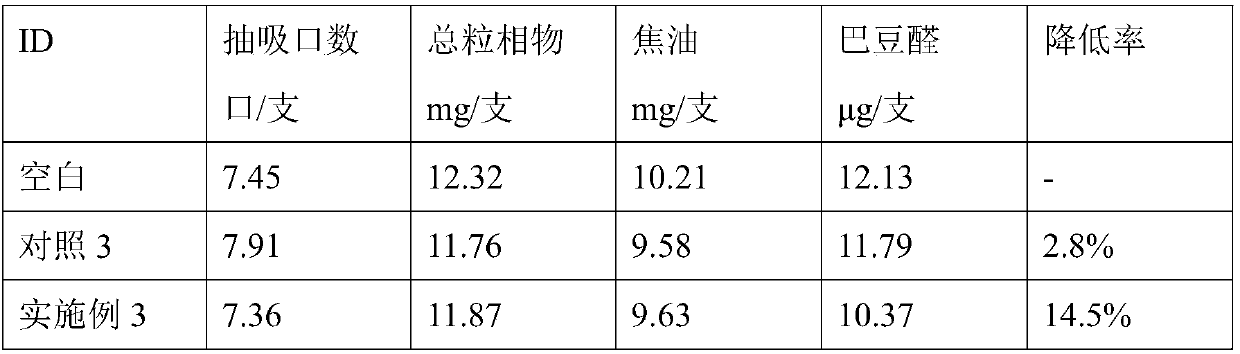

[0035] 100 mg of the above composite material was added to the cigarette tip rod. The prepared cigarettes were analyzed for smoke components, and the results are shown in Table 3, wherein the blank sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com