Medical antibacterial hydrogel dressing preparation method

An antibacterial water and gel technology, applied in the fields of medical science, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of mechanical properties and antibacterial ability need to be further strengthened, so as to promote fusion and dispersion, improve mechanical properties, and improve antibacterial properties. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

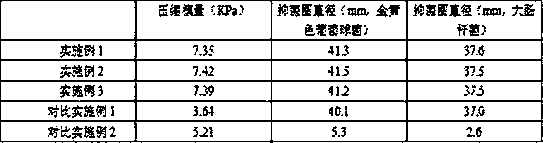

Examples

Embodiment 1

[0019] A method for preparing a medical antibacterial hydrogel dressing, comprising the following steps:

[0020] (1) Add 20 parts by weight of oxidized sodium alginate into distilled water, stir and dissolve for 20 minutes, prepare a 10% oxidized sodium alginate solution, store it in the dark, and set aside;

[0021] (2) Place 40 parts of carboxymethyl chitosan in a vacuum drying oven, dry at 40°C for 5 hours, then add the dried carboxymethyl chitosan to distilled water 20 times its volume, and heat up to 40°C , stirring and dissolving at a speed of 400rpm;

[0022] (3) Add the solution obtained in step (1) to the solution obtained in step (2), continue to stir at 40°C and 400 rpm for 10 minutes, then add 10 parts of graphene oxide-carboxymethyl chitosan spinning fibers, and increase the speed to Stir at 800rpm for 5min, keep the temperature at 40°C, and let stand for 1h to form a gel.

[0023] Further, the preparation method of the graphene oxide-carboxymethyl chitosan spi...

Embodiment (2)

[0031] A method for preparing a medical antibacterial hydrogel dressing, comprising the following steps:

[0032] (1) Add 25 parts by weight of oxidized sodium alginate into distilled water, stir and dissolve for 30 minutes, prepare a 15% oxidized sodium alginate solution, store it in the dark, and set aside;

[0033] (2) Put 45 parts of carboxymethyl chitosan in a vacuum drying oven, dry at 50°C for 7 hours, then add the dried carboxymethyl chitosan to distilled water 22 times its volume, and heat up to 45°C , stirring and dissolving at a speed of 500rpm;

[0034] (3) Add the solution obtained in step (1) to the solution obtained in step (2), continue to stir at 45°C and 500 rpm for 20 minutes, then add 15 parts of graphene oxide-carboxymethyl chitosan spinning fibers, and increase the speed to Stir at 900 rpm for 7 minutes, keep the temperature at 42°C, and let stand for 2 hours to form a gel.

[0035] Further, the preparation method of the graphene oxide-carboxymethyl chi...

Embodiment 3

[0043] A method for preparing a medical antibacterial hydrogel dressing, comprising the following steps:

[0044] (1) Add 30 parts by weight of oxidized sodium alginate into distilled water, stir and dissolve for 40 minutes, prepare a 20% oxidized sodium alginate solution, store it in the dark, and set aside;

[0045] (2) Place 50 parts of carboxymethyl chitosan in a vacuum drying oven, dry at 60°C for 10 hours, then add the dried carboxymethyl chitosan to distilled water 25 times its volume, and heat up to 50°C , stirring and dissolving at a speed of 600rpm;

[0046] (3) Add the solution obtained in step (1) to the solution obtained in step (2), continue to stir at 50°C and 600 rpm for 30 minutes, then add 20 parts of graphene oxide-carboxymethyl chitosan spinning fibers, and increase the speed to Stir at 1000rpm for 10min, keep the temperature at 45°C, and let stand for 3h to form a gel.

[0047] Further, the preparation method of the graphene oxide-carboxymethyl chitosan sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com