Preparation method of antibacterial mildew-proof polypropylene

An antibacterial and mildew proof, polypropylene technology, applied in fiber processing, textile and papermaking, biochemical fiber processing, etc., can solve the problems of not reaching 99% super antibacterial performance, poor antibacterial performance of Candida, and high dosage of antibacterial agents, etc. Achieve broad-spectrum antibacterial and antibacterial properties, the preparation process is simple and easy to control, and the equipment requirements are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

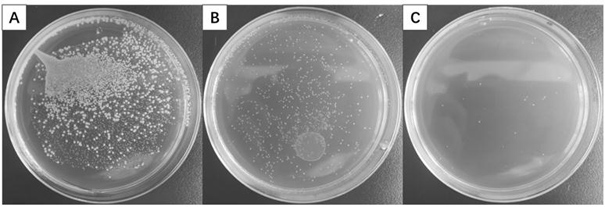

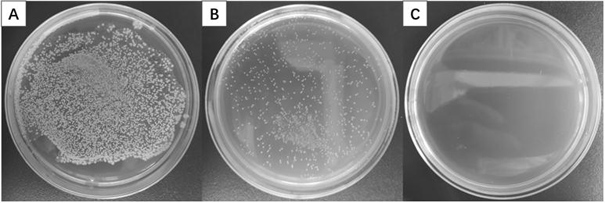

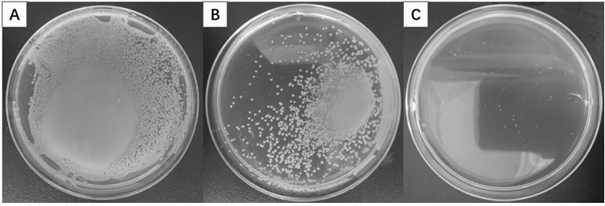

Image

Examples

Embodiment 1

[0031] 1) Measure 50mL of acetone and pour it into a clean beaker, then place it in an ice-water mixture for 10 minutes, weigh 1.84g of cyanuric chloride and add it, and then weigh 1.54g of borneol and dissolve it in 30mL of acetone, Then add 10 mL of deionized water to it, stir evenly, and slowly add it dropwise to the cyanuric chloride solution, react at 0 °C for 5 h, then heat the system to 50 °C, add 1.3 g of monomethyl fumarate, and then add 1.3 g of monomethyl fumarate. The reaction was carried out at the temperature for 5 hours, during which the pH of the system was adjusted to be between 7 and 8 by adding 10wt% sodium carbonate solution dropwise. After the reaction was completed, the composite antibacterial agent was obtained by centrifugation, washing with 75% ethanol solution for many times, and drying.

[0032] 2) Weigh 0.3 g of benzophenone and dissolve it in 20 mL of absolute ethanol, then add 40 mL of acrylic acid, 60 mL of

[0033] deionized water, the system wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com