Method for preparing Janus particles based on lysozyme nano-film

A technology of nano-film and micro-nano particles, which is applied in the field of preparation of Janus particles, achieves the effect of wide applicability, simple operation, and elimination of complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Adjust 10mL of 50mmol / L tris(2-carboxyethyl)phosphine in 4-hydroxyethylpiperazineethanesulfonic acid buffer solution to pH 7.0 with NaOH, and then mix it with 10mL of 2mg / mL lysozyme 4 -Hydroxyethylpiperazineethanesulfonic acid buffer solution is mixed evenly, and then the glass sheet is immersed in the resulting mixture, incubated at room temperature for 5 minutes, so that the surface of the glass sheet is adhered to a layer of lysozyme nano-film, and finally cleaned with deionized water to obtain Glass slides modified with lysozyme nanofilms.

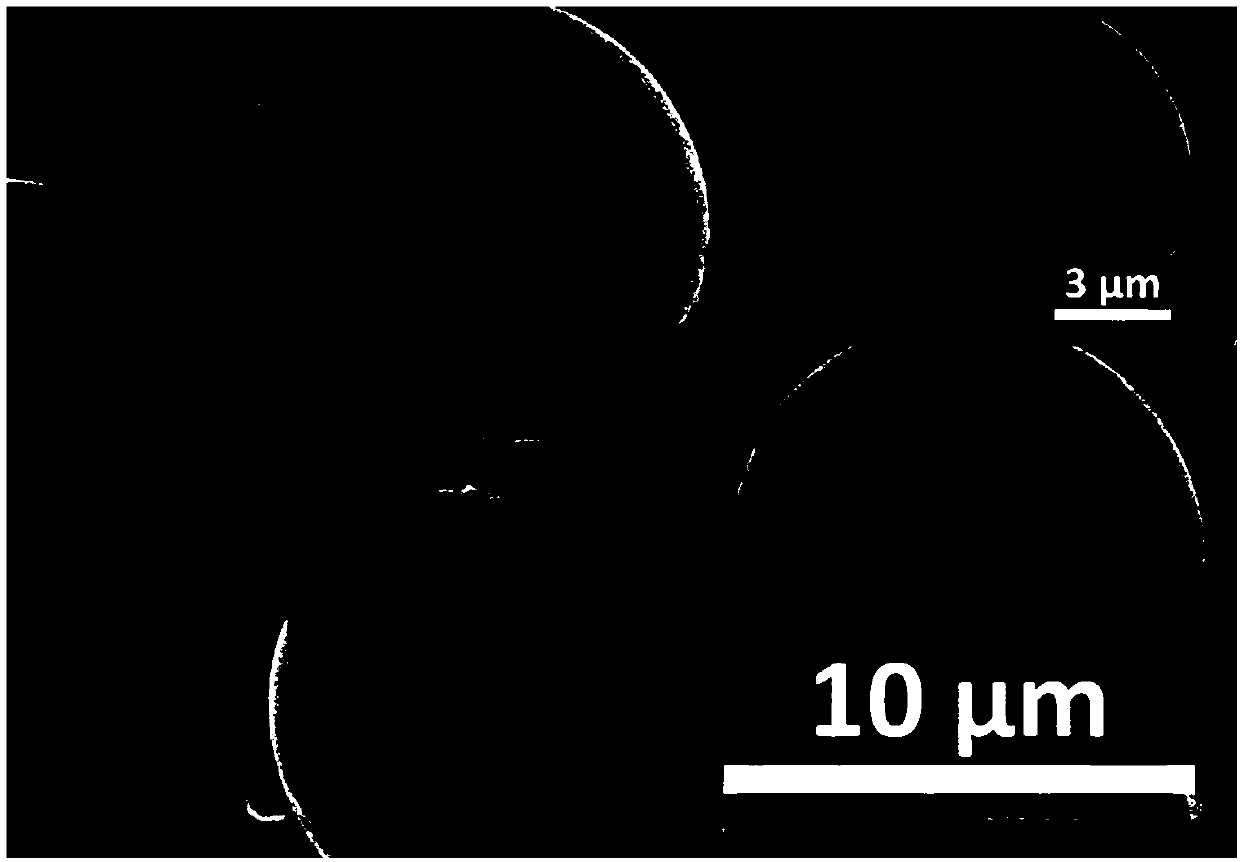

[0018] 2. Uniformly disperse a layer of polystyrene microsphere dispersion liquid with a particle size of 10 μm on the surface of the glass sheet modified by the lysozyme nano-film, and then vacuum-dry it to obtain a glass sheet adsorbing the polystyrene microsphere.

[0019] 3. Adjust 10mL of 50mmol / L tris(2-carboxyethyl)phosphine in 4-hydroxyethylpiperazineethanesulfonic acid buffer solution to pH 7.0 with NaOH, and then m...

Embodiment 2

[0021] 1. Adjust 4-hydroxyethylpiperazineethanesulfonic acid buffer solution of 10mL 40mmol / L tris(2-carboxyethyl)phosphine to pH 7.5 with NaOH, and then mix it with 10mL 2mg / mL lysozyme 4 -Hydroxyethylpiperazineethanesulfonic acid buffer solution is mixed evenly, and then the glass sheet is immersed in the resulting mixture, incubated at room temperature for 5 minutes, so that the surface of the glass sheet is adhered to a layer of lysozyme nano-film, and finally cleaned with deionized water to obtain Glass slides modified with lysozyme nanofilms.

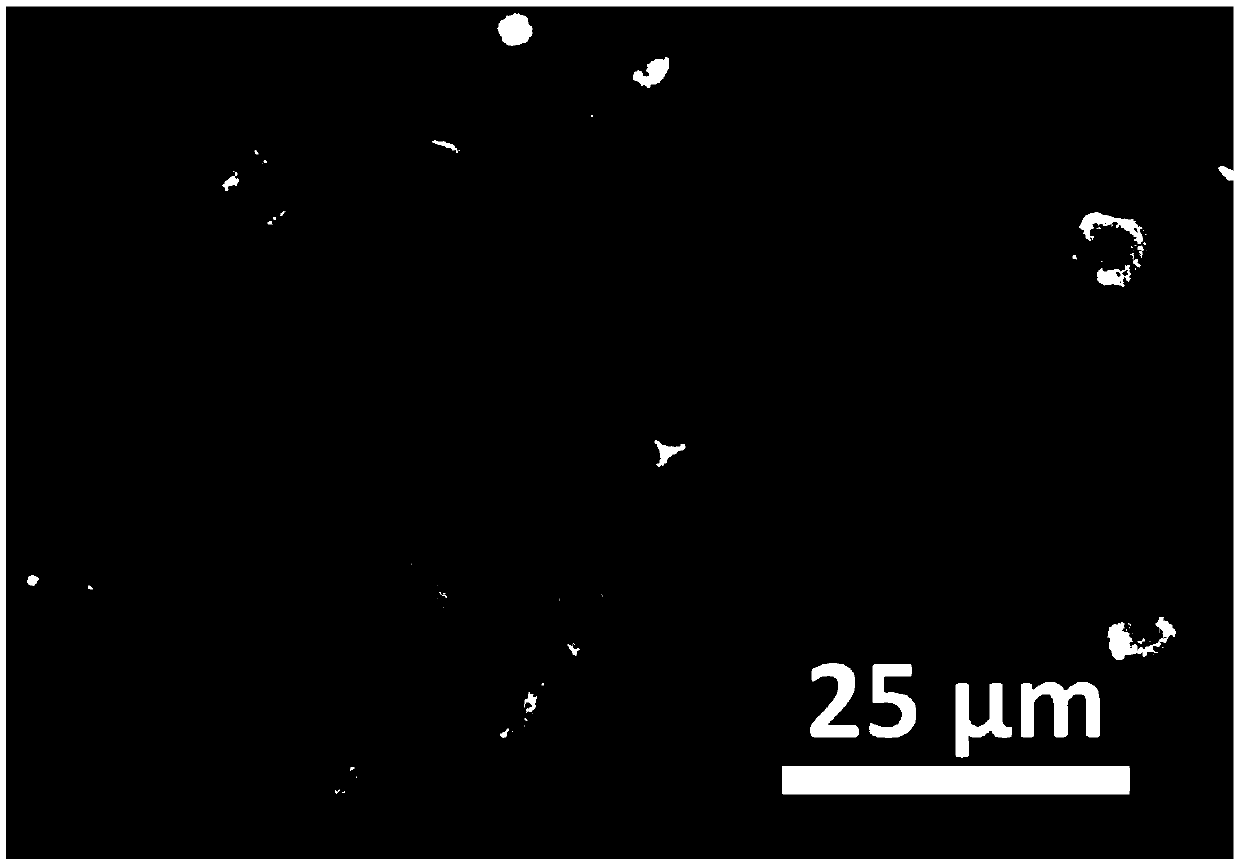

[0022] 2. Uniformly disperse a layer of polystyrene microsphere dispersion liquid with a particle size of 1.5 μm on the surface of the glass sheet modified by the lysozyme nano-film, and then vacuum-dry to obtain a glass sheet adsorbing the polystyrene microsphere.

[0023] 3. Adjust 10mL of 40mmol / L tris(2-carboxyethyl)phosphine in 4-hydroxyethylpiperazineethanesulfonic acid buffer solution to pH 7.5 with NaOH, and then mix it wi...

Embodiment 3

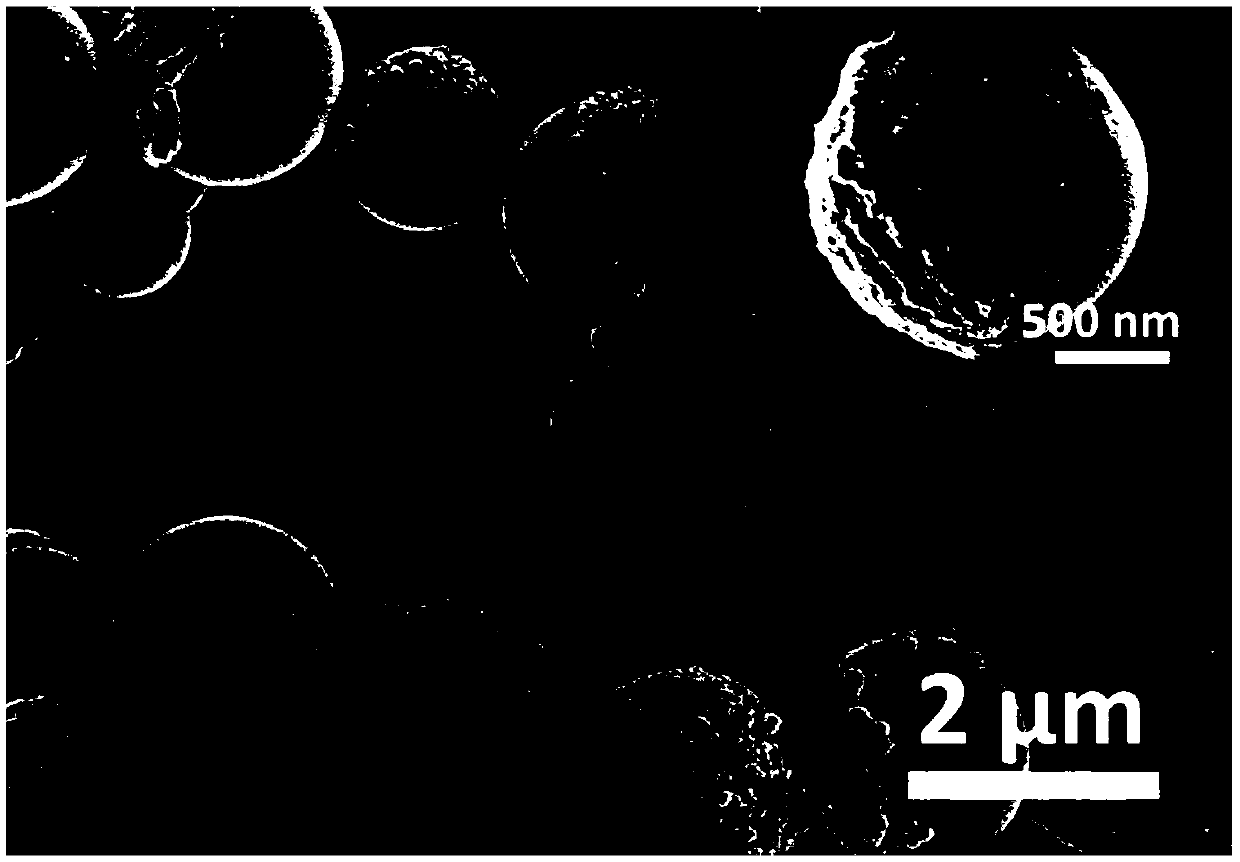

[0025] In this embodiment, the polystyrene microspheres in Example 1 are replaced with silica microspheres with a particle size of 2 μm, and the other steps are the same as in Example 1. The obtained Janus microspheres are as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com