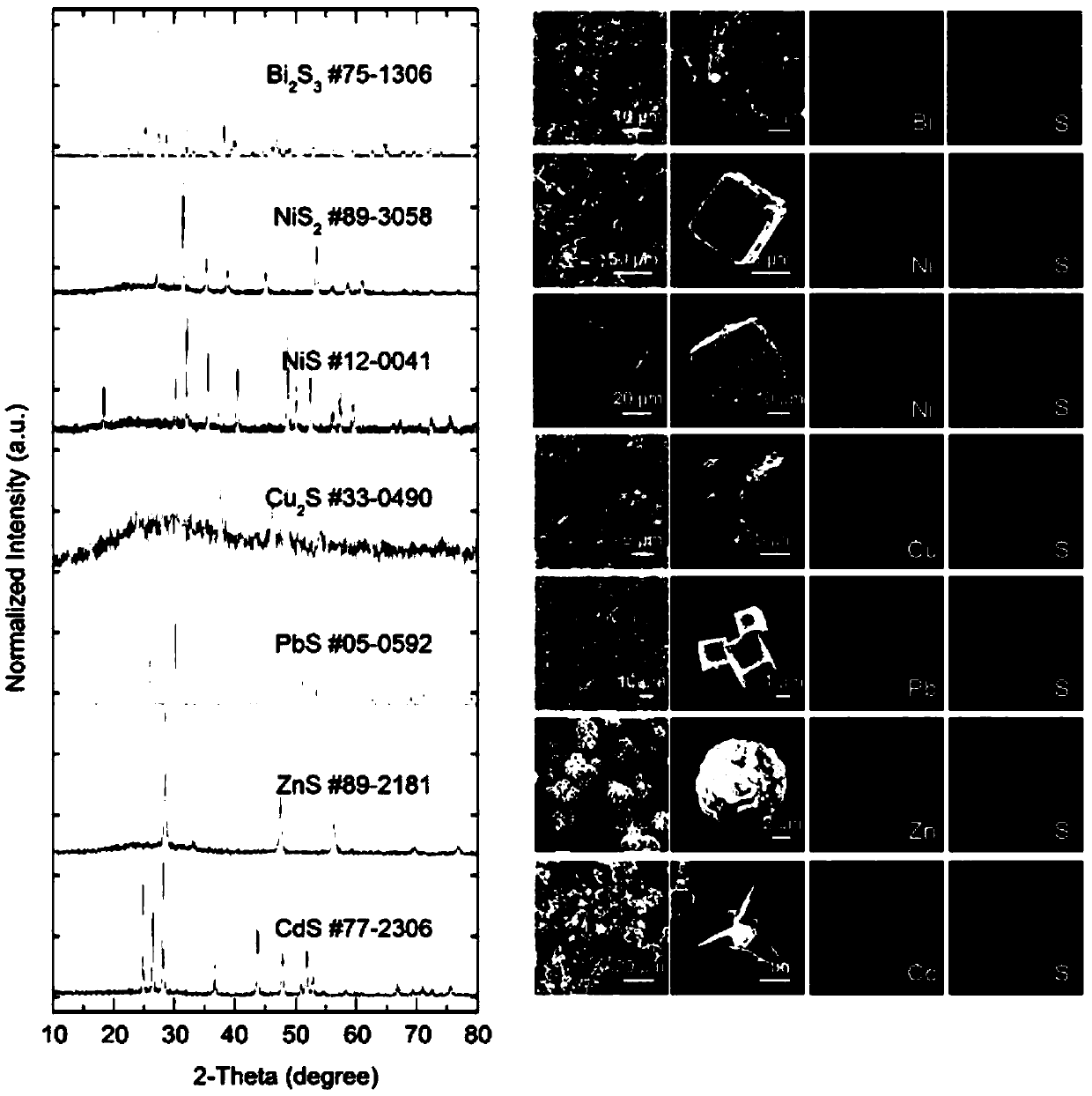

Universal method for preparing nano metal sulfides and complexes thereof in one step

A general method and nano metal technology, applied in the field of nano materials, can solve the problems of increasing the production cost of nano metal sulfides, increasing the cost of wastewater treatment, high reaction temperature, etc., and achieving the effects of low cost, reduced production cost and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation Bi 2 S 3 The method for nanosheet, is characterized in that, comprises the steps:

[0033] (1) Solution preparation: Bi 2 o 3 powder, sublimed sulfur powder and oxalic acid powder were added to deionized water, where Bi 2 o 3 The powder and oxalic acid powder can be dissolved, and the sublimated sulfur powder is uniformly dispersed in the solution, and then the three solutions are mixed, and the concentration of each substance after mixing is 0.0125mol / L, 0.0375mol / L and 0.1125mol / L respectively.

[0034] (2) Reaction: Put the mixed solution into a reaction kettle with a polytetrafluoroethylene lining, and make the volume of the mixed solution account for 60-80% of the total capacity, and then put the reaction kettle into a medium oven at 220°C for reaction 24 hours; after the reaction was completed, the reactor was taken out, and air-cooled to room temperature.

[0035] (3) Sample treatment: Take out the cooled solution, centrifuge at 12000r...

Embodiment 2

[0038] A preparation of NiS 2 The method of micron square is characterized in that, comprises the steps:

[0039] (1) Solution preparation: dissolve NiCl respectively 2 ·6H 2 O powder, sublimed sulfur powder and oxalic acid powder in deionized water, where NiCl 2 ·6H 2 O powder and oxalic acid powder can be dissolved, sublimated sulfur powder is uniformly dispersed in the solution, and then the solutions are mixed, and the concentration of each substance after mixing is respectively 0.025mol / L, 0.025mol / L and 0.025mol / L.

[0040] (2) Reaction: Put the mixed solution into a reaction kettle with a polytetrafluoroethylene lining, and make the volume of the mixed solution account for 60-80% of the total capacity, and then put the reaction kettle into a medium oven at 220°C for reaction 24 hours; after the reaction was completed, the reactor was taken out, and air-cooled to room temperature.

[0041] (3) Sample treatment: Take out the cooled solution, centrifuge at 10000rpm fo...

Embodiment 3

[0044] A method for preparing NiS micron square, is characterized in that, comprises the steps:

[0045] (1) Solution preparation: dissolve NiCl respectively 2 ·6H 2 O powder, sublimed sulfur powder and oxalic acid powder in deionized water, where NiCl 2 ·6H 2 The O powder and the oxalic acid powder can be dissolved, and the sublimated sulfur powder is evenly dispersed in the solution, and then the solutions are mixed, and the concentration of each substance after mixing is respectively 0.025mol / L, 0.025mol / L and 0.075mol / L.

[0046] (2) Reaction: Put the mixed solution into a reaction kettle with a polytetrafluoroethylene lining, and make the volume of the mixed solution account for 60-80% of the total capacity, and then put the reaction kettle into a medium oven at 220°C for reaction 24 hours; after the reaction was completed, the reactor was taken out, and air-cooled to room temperature.

[0047] (3) Sample treatment: Take out the cooled solution, centrifuge at 10000rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com