Method for preparing ethyl acetylpropionate by catalyzing furfural via one-pot method

A technology of ethyl levulinate and furfural, which is applied in the field of ethyl levulinate, can solve the problems of less research on ethyl levulinate, harsh reaction conditions, and high catalyst cost, and achieve cheap raw materials, simple reaction system, and high preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

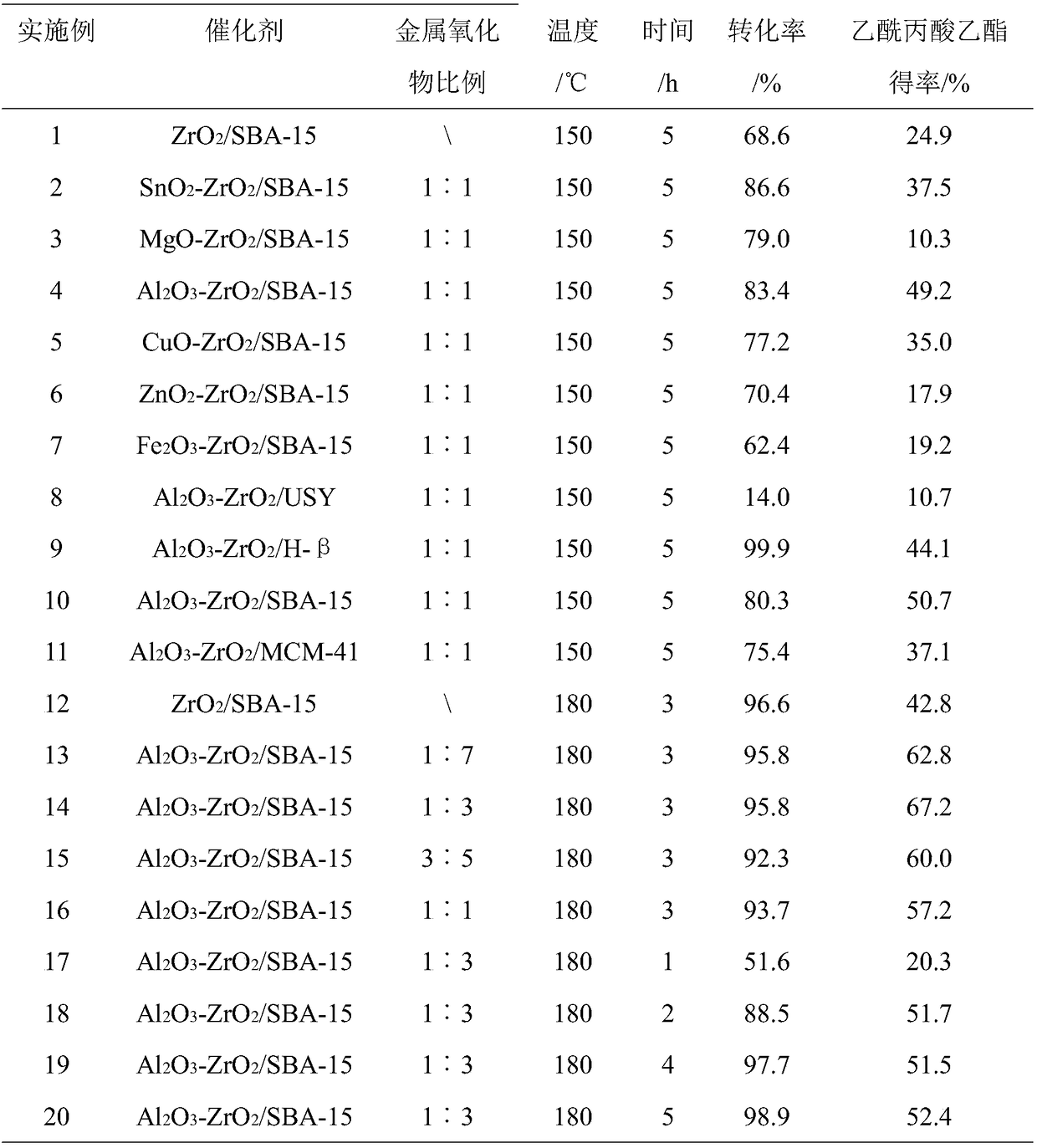

Embodiment 1

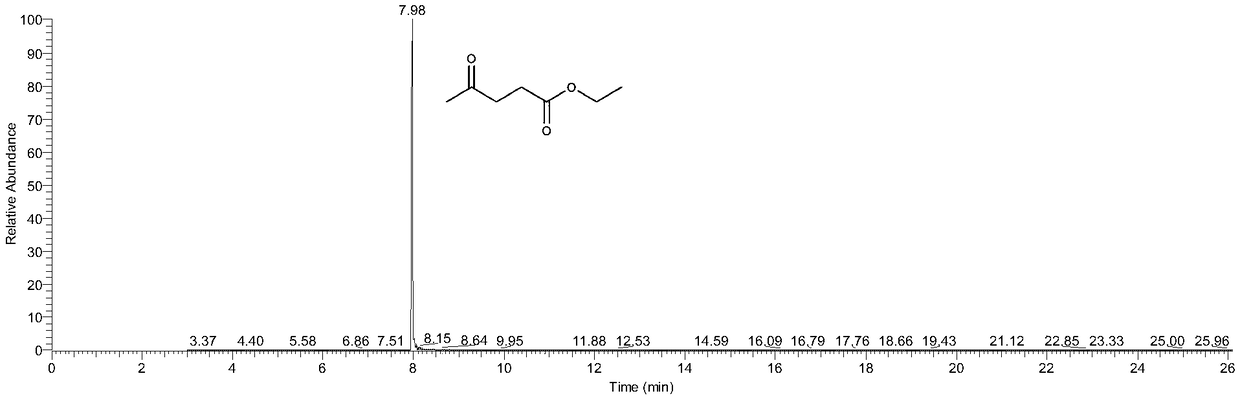

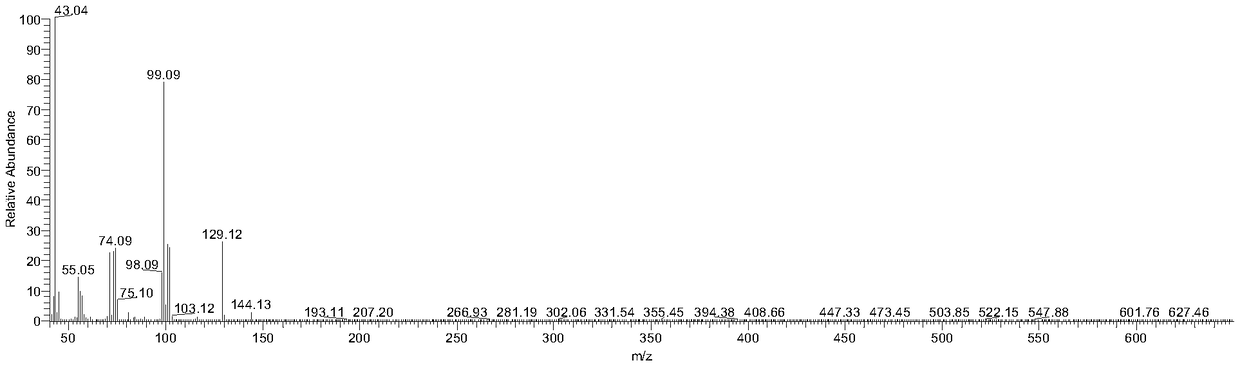

[0022] Add 0.2g furfural and 20mL ethanol to a 50mL autoclave, then add 0.1g ZrO 2 / SBA-15(ZrO 2 Loading capacity 40wt%) as a catalyst, seal the reactor, vigorously stir (800rpm), heat to 150 ° C and keep for 5h, finish the reaction and cool at room temperature, centrifuge the reaction mixture and take the supernatant, use GC-MS (Shimadzu) Qualitative and quantitative detection were carried out with GC (Agilent), and the detection results are listed in Table 1, and the serial number is 1.

Embodiment 2~7

[0024] Add 0.2g furfural and 20mL ethanol to a 50mL autoclave, and then add 0.1g SnO 2 -ZrO 2 / SBA-15, MgO-ZrO 2 / SBA-15, Al 2 o 3 -ZrO 2 / SBA-15, CuO-ZrO 2 / SBA-15, ZnO 2 -ZrO 2 / SBA-15, Fe 2 o 3 -ZrO 2 / SBA-15 (the load of metal oxide is 40wt%, the mixing ratio of the two metal oxides is 1:1) as a catalyst, seal the reactor, stir vigorously (800rpm), heat to 150°C and keep it for 5h, to end the reaction Cool at room temperature, centrifuge the reaction mixture and take the supernatant, use GC-MS (Shimadzu) and GC (Agilent) for qualitative and quantitative detection, the detection results of different catalysts are listed in Table 1, numbered 2-7.

Embodiment 8~12

[0026] Add 0.2g of furfural and 20mL of ethanol to a 50mL autoclave, and then add 0.1g of Al 2 o 3 -ZrO 2 / USY, Al 2 o 3 -ZrO 2 / H-β, Al 2 o 3 -ZrO 2 / SBA-15, Al 2 o 3 -ZrO 2 / MCM-41 (the load of metal oxide is 40wt%, the mixing ratio of the two metal oxides is 1:1) as a catalyst, seal the reactor, stir vigorously (800rpm), heat to 150°C and keep it for 5h, to end the reaction Cool at room temperature, centrifuge the reaction mixture and take the supernatant, and use GC-MS (Shimadzu) and GC (Agilent) for qualitative and quantitative detection. The detection results of different catalysts are listed in Table 1, numbered 8-11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com