Ultraviolet photo-curing photosensitive resin for 3D printing and preparation method thereof

A photosensitive resin and 3D printing technology, applied in the field of 3D printing materials, can solve the problems of slow curing speed and high viscosity of photocurable materials, and achieve the effects of good retention, low volume shrinkage and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

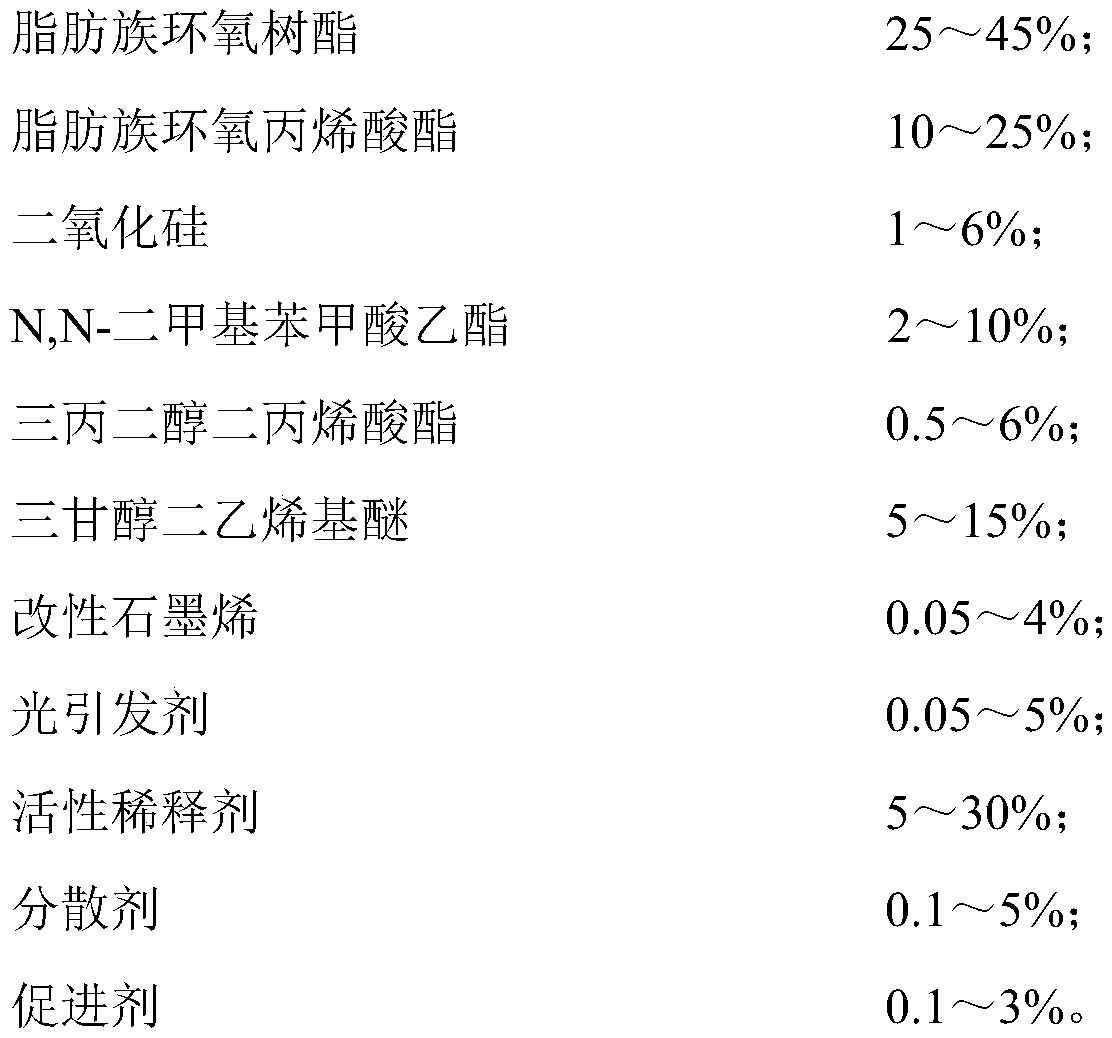

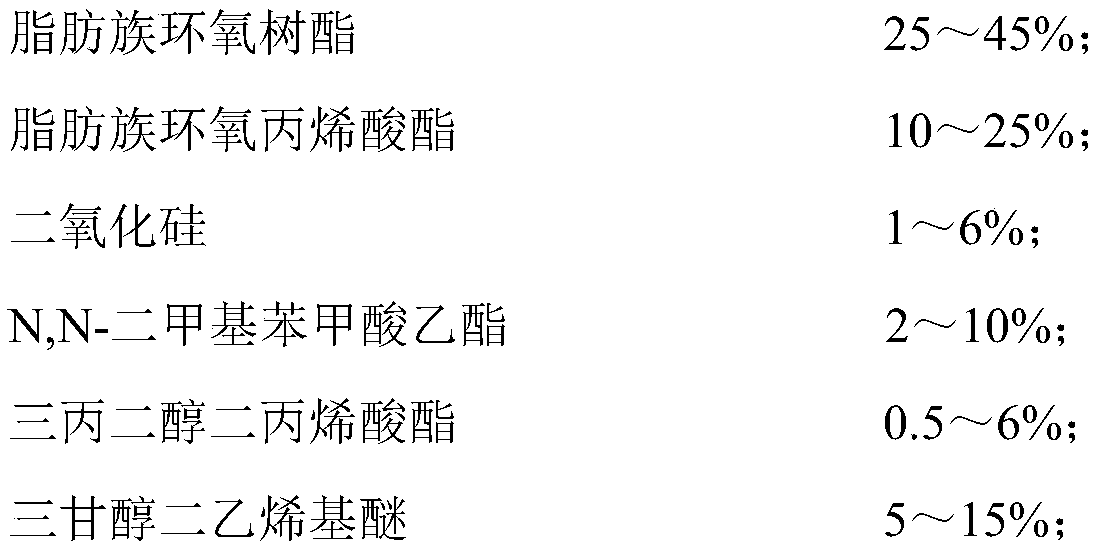

[0035] This embodiment provides a UV-curable photosensitive resin for 3D printing, its components and mass percentages are: 45wt.% aliphatic epoxy resin, 25wt.% aliphatic epoxy acrylate, 6wt.% carbon dioxide Silicon, 2wt.% N,N-ethyl dimethylbenzoate, 1.9wt.% tripropylene glycol diacrylate, 5wt.% triethylene glycol divinyl ether, 3wt.% modified graphene, 5wt.% light Initiator, 5wt.% reactive diluent, 0.1wt.% dispersant, 2wt.% accelerator.

[0036] Preparation:

[0037] A. Add aliphatic epoxy resin, aliphatic epoxy acrylate, silicon dioxide, N,N-ethyl dimethylbenzoate to the reaction kettle equipped with stirrer, thermometer, condenser and feeding tank , tripropylene glycol diacrylate, triethylene glycol divinyl ether, modified graphene and reactive diluent, and stir evenly for 60 minutes;

[0038] B. In the reaction kettle, add a dispersant and stir evenly for 50 minutes;

[0039] C. Add photoinitiator and accelerator into the reaction kettle, the temperature of the reaction...

Embodiment 2

[0042] This embodiment provides a UV-curable photosensitive resin for 3D printing, its components and mass percentages are: 25wt.% aliphatic epoxy resin, 25wt.% aliphatic epoxy acrylate, 1wt.% carbon dioxide Silicon, 10wt.% N,N-ethyl dimethylbenzoate, 0.5wt.% tripropylene glycol diacrylate, 15wt.% triethylene glycol divinyl ether, 4wt.% modified graphene, 5wt.% light Initiator, 6.5wt.% reactive diluent, 5wt.% dispersant, 3wt.% accelerator.

[0043] Preparation:

[0044] A. Add aliphatic epoxy resin, aliphatic epoxy acrylate, silicon dioxide, N,N-ethyl dimethylbenzoate to the reaction kettle equipped with stirrer, thermometer, condenser and feeding tank , tripropylene glycol diacrylate, triethylene glycol divinyl ether, modified graphene and reactive diluent, and stir evenly for 60 minutes;

[0045] B. In the reaction kettle, add dispersant and stir evenly for 5 minutes;

[0046] C. Add photoinitiator and accelerator into the reaction kettle, the temperature of the reaction ...

Embodiment 3

[0049]This embodiment provides a UV-curable photosensitive resin for 3D printing, its components and mass percentages are: 35wt.% aliphatic epoxy resin, 10wt.% aliphatic epoxy acrylate, 3.5wt.% Silicon oxide, 6wt.% N, N-ethyl dimethylbenzoate, 6wt.% tripropylene glycol diacrylate, 10wt.% triethylene glycol divinyl ether, 0.05wt.% modified graphene, 0.05wt. % photoinitiator, 24.3wt.% reactive diluent, 5wt.% dispersant, 0.1wt.% accelerator.

[0050] Preparation:

[0051] A. Add aliphatic epoxy resin, aliphatic epoxy acrylate, silicon dioxide, N,N-ethyl dimethylbenzoate to the reaction kettle equipped with stirrer, thermometer, condenser and feeding tank , tripropylene glycol diacrylate, triethylene glycol divinyl ether, modified graphene and reactive diluent, and stir evenly for 35 minutes;

[0052] B. In the reaction kettle, add dispersant and stir evenly for 25 minutes;

[0053] C. Add photoinitiator and accelerator into the reaction kettle, the temperature of the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com