Mobile gas seal detection system applicable to oil field site

A detection system and air-tight technology, which is applied in liquid-tightness measurement using liquid/vacuum degree, and by measuring the rate of increase and deceleration of fluid, can solve the problem of affecting corporate image and reputation, threatening the safety of on-site staff and peripheral equipment, Unreliable sealing and other problems, to eliminate oil drilling safety risks, avoid oil and gas production downtime, and avoid leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Attached below Figure 1-5 Specific embodiments of the present invention will be further described.

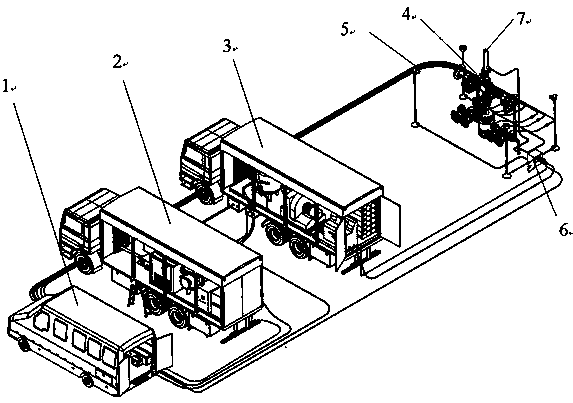

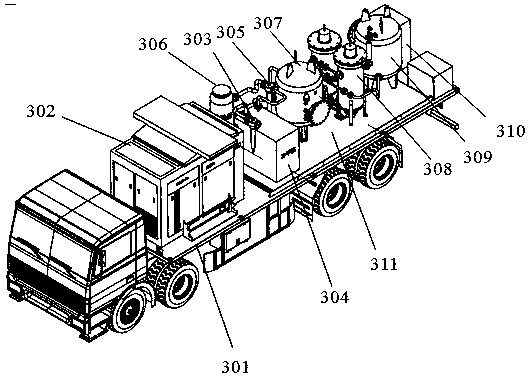

[0019] Field layout of the present invention such as figure 1 As shown, the seat seal device 7 is installed on the wellhead equipment 4 to isolate the internal pressure channel between the wellbore and the wellhead equipment, and the nitrogen generator vehicle 3, the nitrogen booster vehicle 2, and the instrument vehicle 1 are placed in sequence 50 meters away from the wellhead , the on-site pressure relief cabinet is placed near the wellhead equipment 4, four video monitoring heads 5 are placed around the wellhead equipment 4, all power lines, signal lines, monitoring lines and high-pressure hoses are connected, and the mobile airtight detection system is started, namely Water pressure and airtight tests can be carried out on the wellhead equipment.

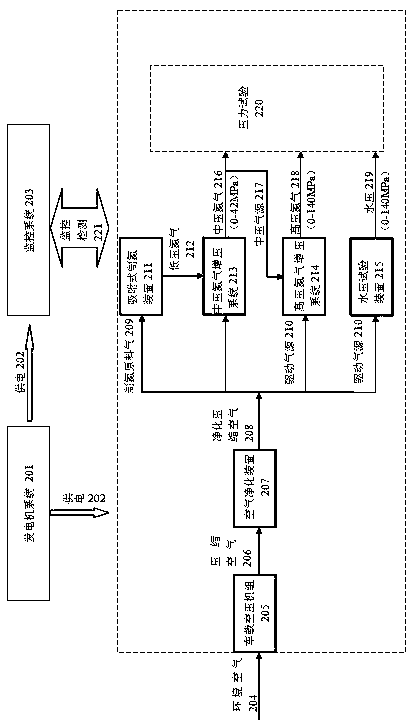

[0020] The experimental workflow of the present invention is as figure 2 As shown, the generator system 201 is firs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap