Method for preparing tetraamminepalladium hydrogen carbonate

A technology of tetraammine palladium bicarbonate and sodium bicarbonate, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc., can solve high cost, long operation process, discomfort Due to problems such as large-scale production, it achieves the effects of low pollution, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

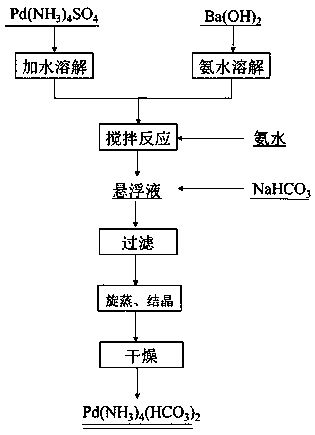

Method used

Image

Examples

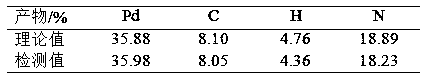

Embodiment 1

[0023] Weigh 10g of tetraammine palladium sulfate (Pd: 39%), add 10mL of deionized water to dissolve, and prepare an aqueous solution of tetraammine palladium sulfate; weigh 9.38g of hydrated barium hydroxide, add 10mL of ammonia water to dissolve, and prepare the ammonia of barium hydroxide Aqueous solution: Slowly add the ammonia solution of barium hydroxide into the tetraammonia palladium sulfate aqueous solution, keep the pH of the reaction process at 11, and obtain 20mL containing BaSO after reacting for 30min 4 Precipitated suspension. Aqueous ammonia 20mL was added, and the reaction was stirred for 2h. Add an aqueous solution containing 6.2g of sodium bicarbonate, continue to stir and react for 2 hours, filter with slow filter paper, distill the filtrate at 60°C under negative pressure (P=-0.08MPa) until a crystal film appears, and place it in an ice-water bath to crystallize , the crystals were filtered and dried to obtain tetraammine palladium bicarbonate product wit...

Embodiment 2

[0027] Weigh 10g of tetraammine palladium sulfate (Pd: 39%), add 10mL of deionized water to dissolve, and prepare an aqueous solution of tetraammine palladium sulfate; weigh 17.49g of hydrated barium hydroxide, add 10mL of ammonia water to dissolve, and prepare the ammonia of barium hydroxide Aqueous solution: Slowly add the ammonia solution of barium hydroxide into the tetraammonia palladium sulfate aqueous solution, keep the pH of the reaction process at 12, and obtain 20mL containing BaSO after reacting for 30min 4 Precipitated suspension. Aqueous ammonia 20mL was added, and the reaction was stirred for 2h. Add an aqueous solution containing 24.9g of sodium bicarbonate, continue to stir and react for 2 hours, filter with slow filter paper, distill the filtrate at 60°C under negative pressure (P=-0.08MPa) until a crystal film appears, and place it in an ice-water bath to crystallize , the crystals were filtered and dried to obtain tetraammine palladium bicarbonate product w...

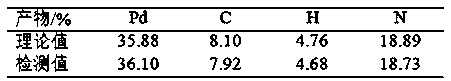

Embodiment 3

[0031] Weigh 100g of palladium tetraammine sulfate (Pd: 39%), add 100mL of deionized water to dissolve, and prepare an aqueous solution of tetraammine palladium sulfate; weigh 105g of hydrated barium hydroxide, add 100mL of ammonia water to dissolve, and prepare an ammonia solution of barium hydroxide ; The ammonia solution of barium hydroxide is slowly added in the tetraammonia palladium sulfate aqueous solution, the pH that keeps reaction process is 12, after reacting 30min, obtain 200mL containing BaSO 4 Precipitated suspension. Ammonia water 200mL was added, and the reaction was stirred for 2h. Add an aqueous solution containing 155.5g of sodium bicarbonate, continue to stir and react for 2.5h, filter with slow filter paper, distill the filtrate at 40°C under negative pressure (P=-0.06MPa) until a crystalline film appears, and place it at 0°C crystallized, and the crystals were filtered and dried to obtain tetraammine palladium bicarbonate product with a yield of 92.5%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com