A frequency tunable antenna and its manufacturing method

An antenna and frequency technology, applied in the field of frequency adjustable antenna and its production, can solve the problems of increasing cost, increasing process complexity, and failing to achieve electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

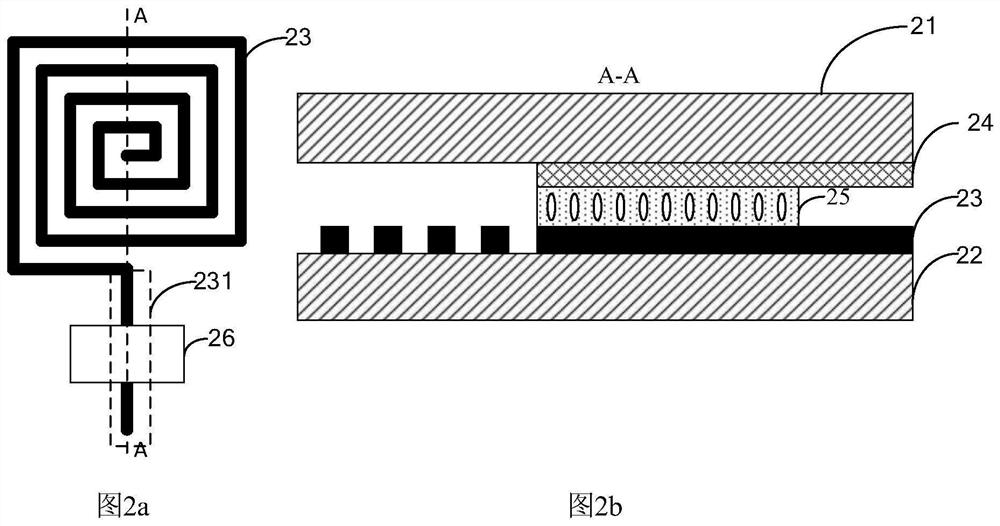

[0070] refer to Figure 2a with 2b as shown ( Figure 2a It is a top view of the frequency adjustable antenna, 2b is an enlarged cross-sectional view of the frequency adjustable antenna), this embodiment provides a frequency adjustable antenna as a coil antenna, including:

[0071] The first substrate 21 and the second substrate 22 facing each other, the coil electrode 23 disposed on the second substrate 22 on the side close to the first substrate 21, and the antenna disposed on the side of the first substrate 21 close to the second substrate 22 are grounded. Pole 24; Exemplarily, in the embodiment of the present invention, the liquid crystal drive electrode is an antenna ground electrode, and the antenna electrode is a coil electrode 23 wound in a preset direction, specifically a microstrip line;

[0072] Wherein, the liquid crystal layer 25 is arranged between the feeding part 231 of the coil electrode 23 and the antenna ground electrode 24; wherein, the orthographic proje...

Embodiment 2

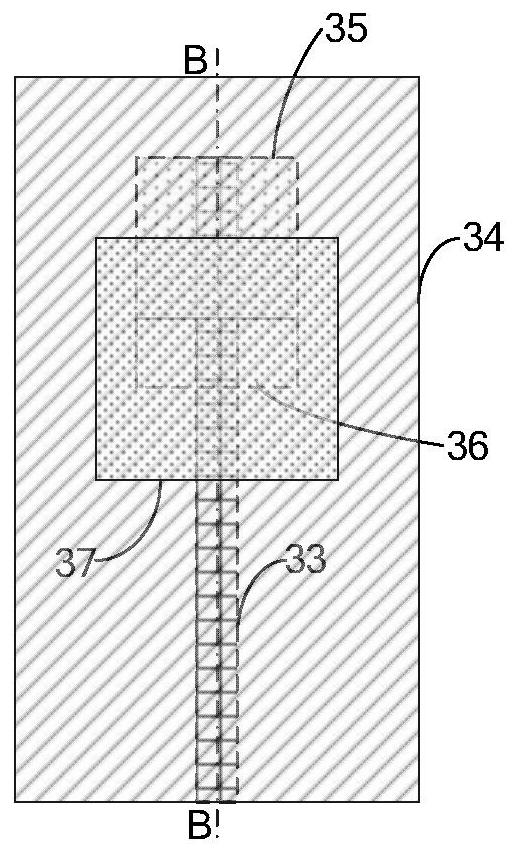

[0078] refer to Figure 3a with 3b as shown ( Figure 3a It is a top view of the slot-coupled patch antenna, 3b is an enlarged cross-sectional view of the slot-coupled patch antenna), and this embodiment provides a frequency-tunable antenna as a slot-coupled patch antenna, including:

[0079] The first substrate 31 and the second substrate 32 facing each other, the antenna electrode 33 disposed on the second substrate 32 on the side close to the first substrate 31, and the antenna electrode 33 disposed on the side of the first substrate 31 close to the second substrate 32 are grounded. Pole 34; Exemplarily, in the embodiment of the present invention, the liquid crystal driving electrode is an antenna ground electrode, and the antenna electrode is a microstrip line;

[0080] The frequency adjustable antenna also includes a patch electrode 37, the patch electrode 37 is arranged on the side of the first substrate 31 away from the second substrate 32, the antenna ground electrod...

Embodiment 3

[0086] refer to Figure 4a with 4b as shown ( Figure 4a is a top view of the coplanar waveguide feeding coil antenna, 4b is an enlarged cross-sectional view of the coplanar waveguide feeding coil antenna), and this embodiment provides a frequency adjustable antenna which is a coplanar waveguide feeding coil antenna.

[0087] The coplanar waveguide feeding coil antenna includes a first substrate 41 and a second substrate 42 opposite to each other, a coplanar waveguide electrode 43 disposed on the second substrate 42 close to the first substrate 41, and a coplanar waveguide electrode 43 disposed on the first substrate 41 close to the first substrate 41. The liquid crystal driving electrode 44 on one side of the second substrate 42 ; for example, in the embodiment of the present invention, the antenna electrode is the coplanar waveguide electrode 43 .

[0088] The coplanar waveguide electrode 43 includes a feeding section and a coil section 43-1.

[0089] In the coplanar wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com