Process for producing super critical extracting caterpillar fungus deoxynucleoside

A deoxynucleoside and supercritical technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve problems such as high energy consumption, cumbersome operation, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

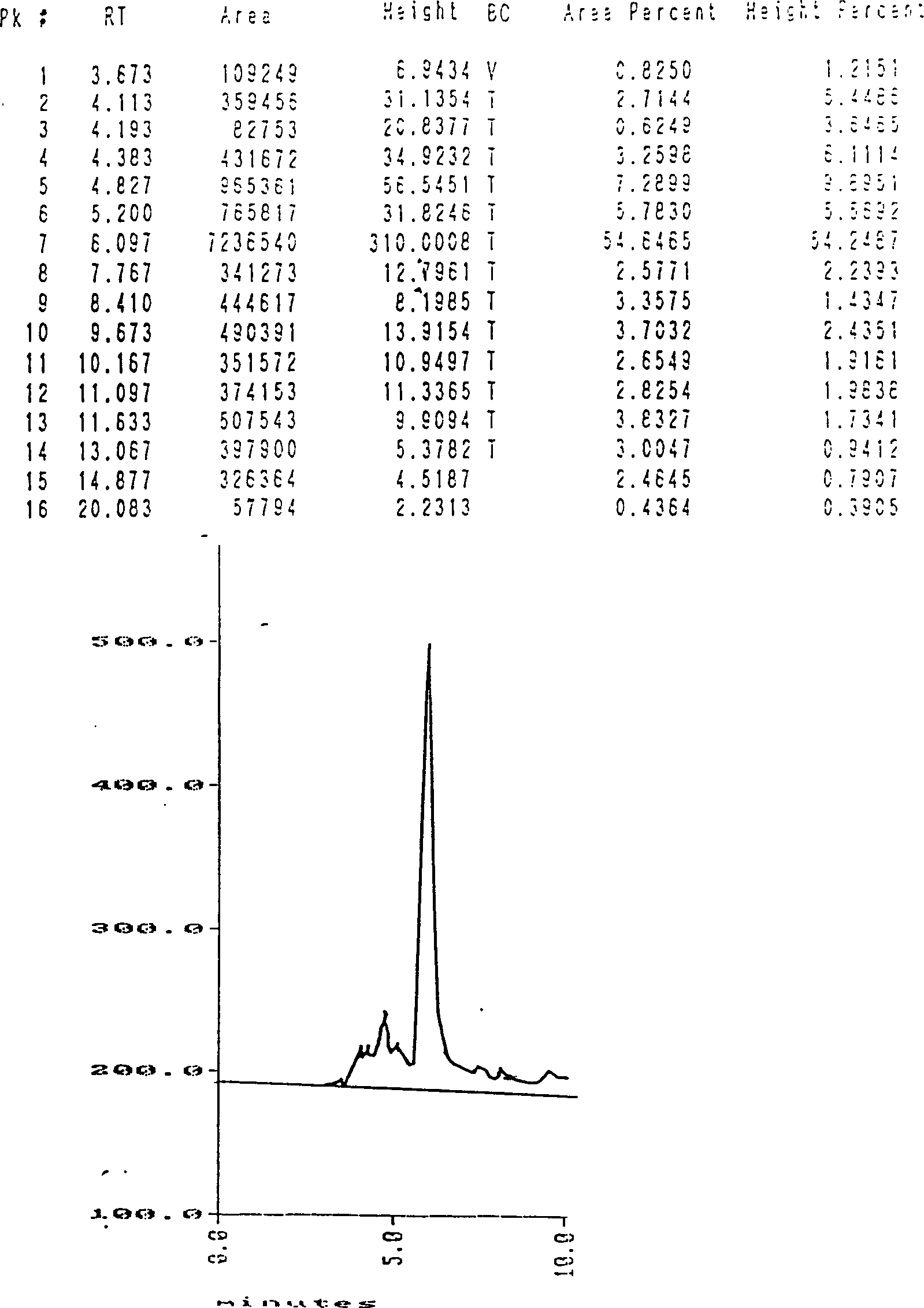

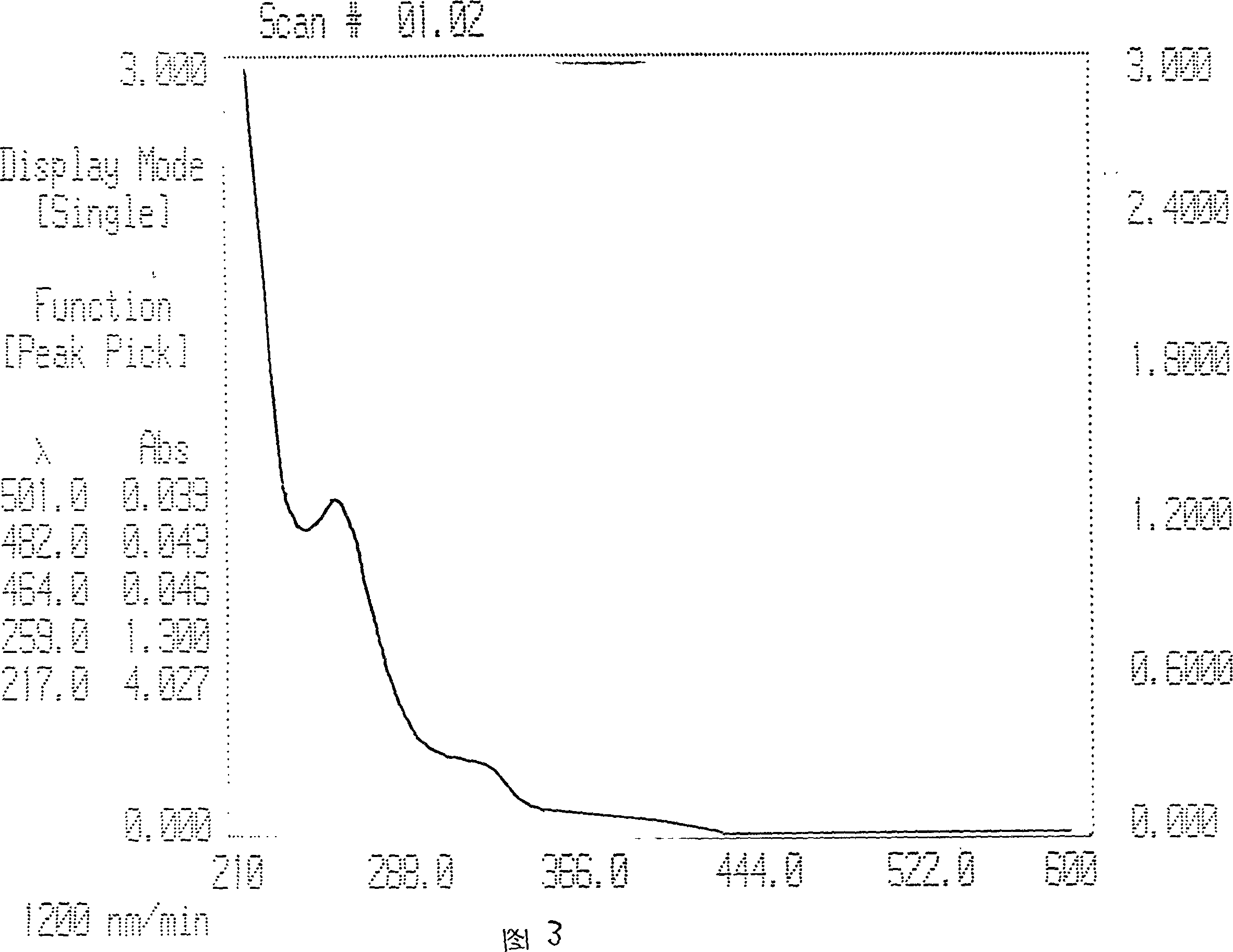

[0032] Example 1, take 0.75 kg of Cordyceps militaris rice culture medium, crush it through a 20-60 mesh sieve, and put it into an extraction kettle with a content of 1.4 mg / g of cordycepin, using supercritical carbon dioxide extraction technology, conditions: 50°C, 35Mpa, 20L / h, flow extraction after equilibrating for 15 minutes. Separation is carried out after extraction, enters separation tank, separation tank pressure 6Mpa, 30 ℃, after 2 hours sampling obtains about 40ml of aqueous matter (lower layer>: upper layer is oily matter. Add 10% ethanol each 200ml in three times as entrainer, each After extraction for 1-2 hours, extract about 540ml, combine with activated carbon to remove impurities, and concentrate in vacuo to obtain 235mg of light yellow granules with a cordycepin content of 75.05%. The yield is about 16.79%. The finished product meets the requirements of the second-class new drug declaration. To increase the yield, the entrainer can be used repeatedly for extr...

Embodiment 2

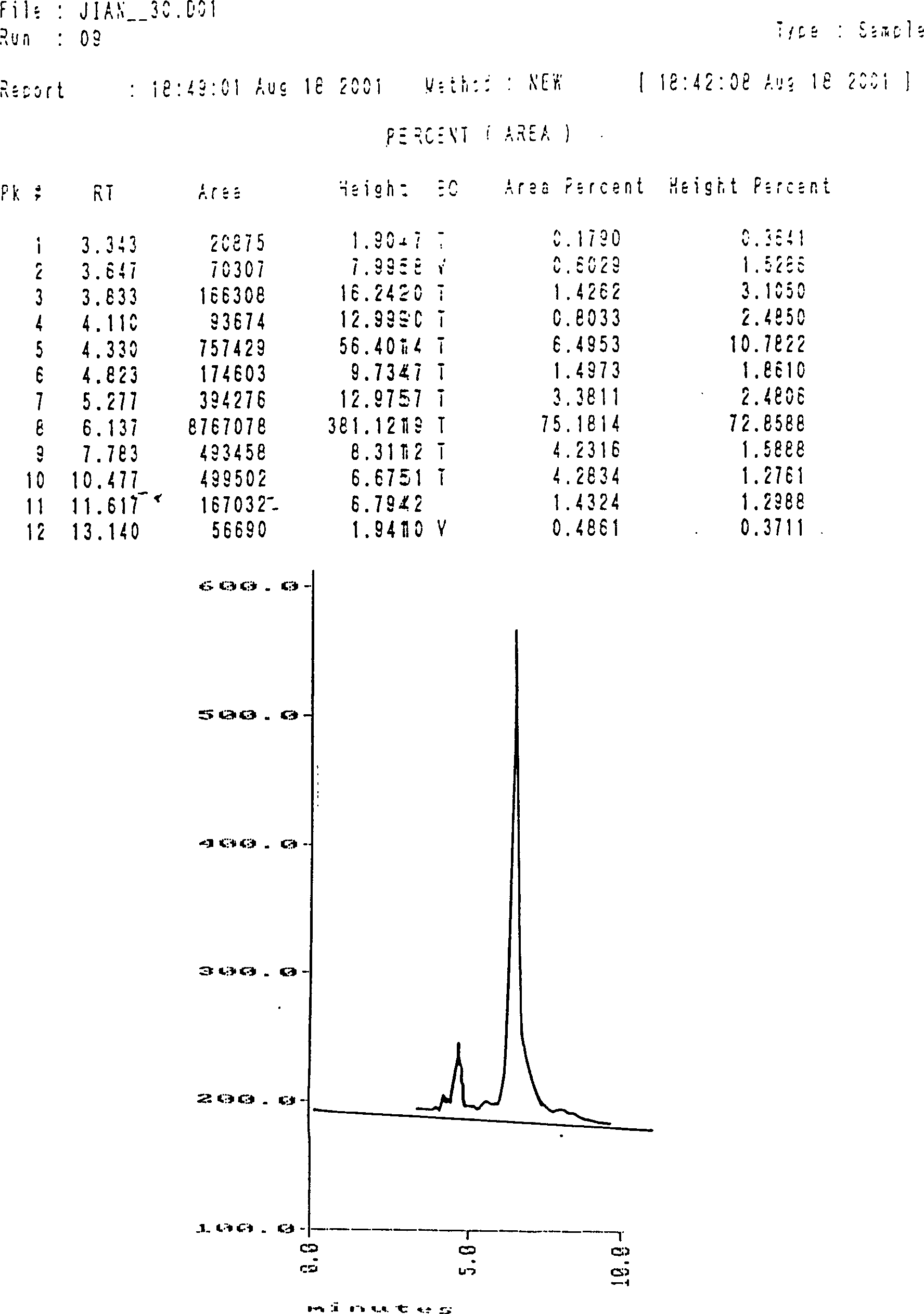

[0034] Example 2, weigh 0.75 kg of Cordyceps militaris solid fermentation powder, crush and sieve (the content of cordycepin > 1.0mg / g), put it into an extraction kettle, and use supercritical carbon dioxide extraction technology, conditions: 60°C, 30Mpa, 15L / h, flow extraction after equilibrium. First obtain the mixture of Cordyceps oil and water, remove the oil through a separatory funnel, and then extract with 70% ethanol as an entrainer, adding 200ml each time or by continuously adding the entrainer. Separation is carried out after extraction, enters the separation tank, the conditions of the separation tank are 35°C, 5Mpa, 20L / h, and 600ml of light yellow liquid is obtained. Remove impurities, concentrate, and crystallize according to conventional methods to obtain 245 mg of light yellow granules, remove impurities with organic reagents to obtain 160 mg of white crystals with a purity of 98.6%.

Embodiment 3

[0036] 500 mg of cordycepin monomer obtained by this method was dissolved in 50 ml of double distilled water, filtered through a glass filter G6, packed into sterile penicillin vials, 2.5 ml per bottle, and processed on a lyophilizer in a sterile room for 24 hours. into a white spongy object, sealed with a cap, that is, lyophilized injection of cordycepin 25mg / support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com