Insect-prevention medical membrane and preparation method thereof

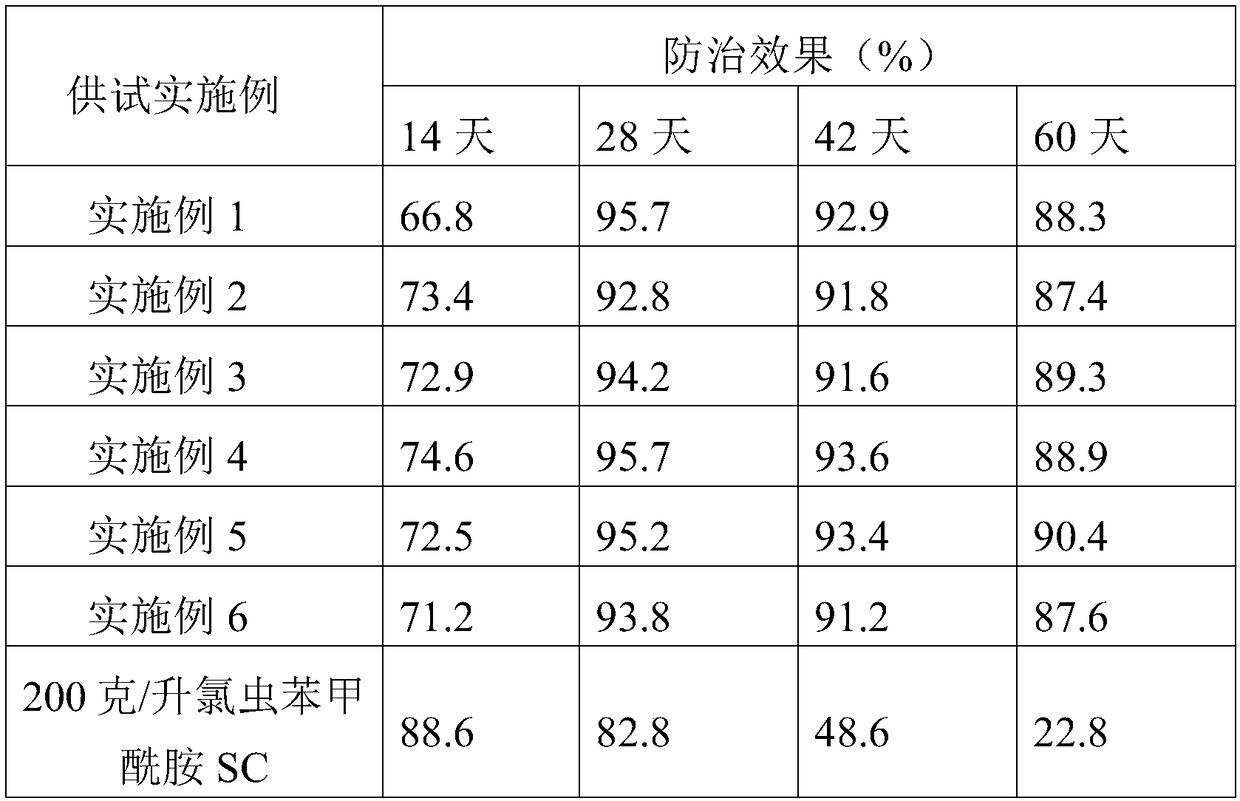

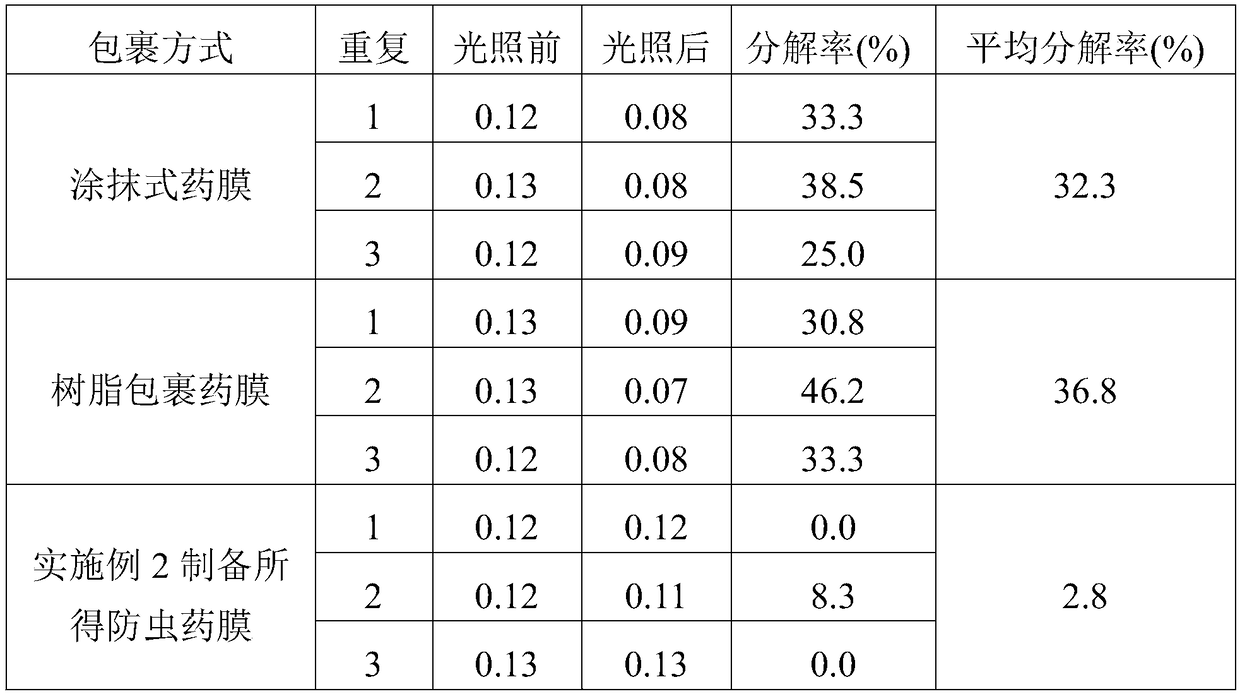

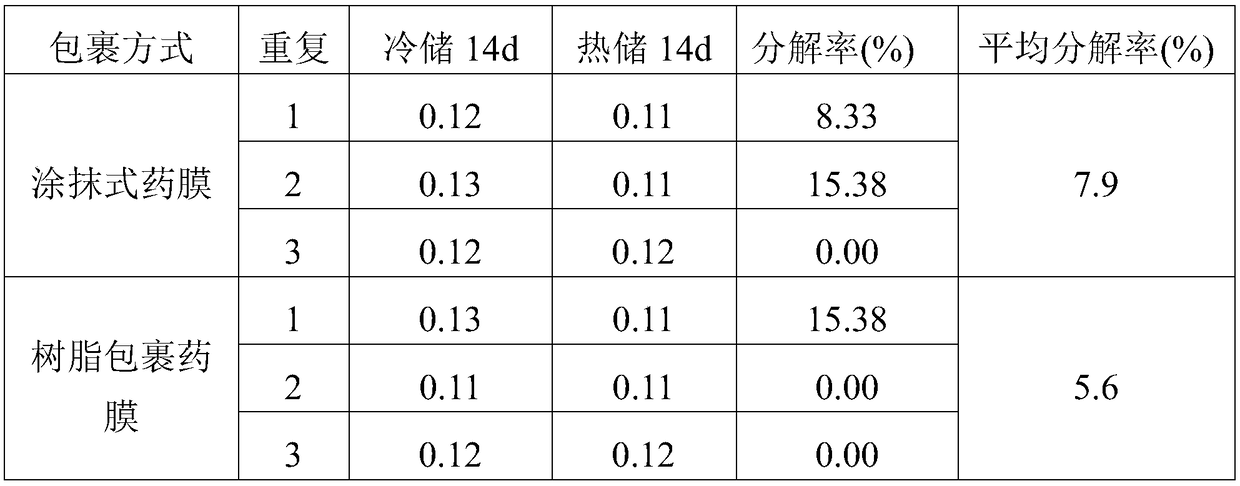

A technology of insect repellent and insecticide, applied in the field of insect repellent film and its preparation, can solve problems such as difficult release, failure to achieve control, and failure to release active ingredients, so as to achieve uniform drug effect release, simple product production, and improved Effects on Sugarcane Yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of an insect repellent drug film, the operation steps are as follows:

[0023] (1) Take kg as the unit, weigh the following components, and add up all components to a total of 100kg: insecticide chlorantraniliprole 0.3kg, anti-photolysis agent UV-9 (2-hydroxyl-4-methoxy Benzophenone) 0.8kg, surfactant calcium dodecylbenzenesulfonate 1.1kg, phosphate ester 1.0kg, stearic acid 1.5kg, starch 2.5kg, ethylene oxide 1.5kg, the balance is polyethylene resin , that is, the polyethylene resin is 91.3kg; then the insecticide, surfactant and anti-photolysis agent are mixed in a mixer for 15 minutes, mixed evenly, and then extruded in a twin-screw extruder at a temperature of 50 ° C. Press and granulate, pass through a 60-mesh sieve, and make insecticide masterbatches with a particle size of 0.01-0.25mm;

[0024] (2) Step (1) is weighed gained phosphoric acid ester, stearic acid, starch, ethylene oxide, polyethylene resin and step (1) to prepare gained insecti...

Embodiment 2

[0026] A preparation method of an insect repellent drug film, the operation steps are as follows:

[0027] (1) Take kg as the unit, weigh the following components, and add up all components to a total of 100kg: insecticide chlorantraniliprole 1.8kg, anti-photolysis agent UV-531 (2-hydroxy-4-n-octyloxy benzophenone) 19kg, surfactant sodium lignosulfonate 0.8kg, phosphate ester 1.0kg, stearic acid 2.0kg, starch 1.6kg, ethylene oxide 2.0kg, the balance is polyethylene resin, that is, poly Vinyl resin is 71.8kg; then the insecticide, surfactant and anti-photolysis agent are mixed in a mixer for 15 minutes, mixed evenly, and then extruded and granulated in a twin-screw extruder at a temperature of 70°C , through a 60-mesh sieve to make insecticide masterbatches with a particle size of 0.01-0.25mm;

[0028] (2) after phosphoric acid ester, stearic acid, starch, ethylene oxide, polyethylene resin and step (1) prepare the gained insecticide masterbatch and mix 5min in the blender in ...

Embodiment 3

[0030] A preparation method of an insect repellent drug film, the operation steps are as follows:

[0031] (1) Take kg as the unit, weigh the following components, and add up all components to a total of 100kg: insecticide cyantraniliprole 0.6kg, anti-photolysis agent UV-9 (2-hydroxy-4-methoxy Benzophenone) 3.6kg, surfactant alkylnaphthalene sodium sulfonate 0.2kg and sodium lignosulfonate 1.8kg, phosphoric acid ester 1.0kg, stearic acid 1.2kg, starch 4.2kg, ethylene oxide 0.8kg, The balance is polyethylene resin, that is, polyethylene resin 86.6kg; then mix the insecticide, surfactant and anti-photolysis agent in a mixer for 15 minutes, mix evenly, and then extrude in a twin-screw extruder at a temperature of 60°C Extrude and granulate in the machine, and pass through a 60-mesh sieve to make insecticide masterbatches with a particle size of 0.01-0.25mm;

[0032] (2) after phosphoric acid ester, stearic acid, starch, ethylene oxide, polyethylene resin and step (1) prepare the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com