A kind of microcapsule type potato whole powder and its preparation method and application

A technology of potato whole powder and microcapsules, which is applied in the food field, can solve the problems of potato browning, low gelatinization degree, low PPO activity, etc., and achieves the effects of no color-protecting agent addition, low equipment requirements, and easy-to-master technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 potato powder

[0043] Proceed as follows:

[0044] (1) In this example, "Zhongyao 18" was used as the raw material, and fresh, regular-shaped, disease-free and mechanically damaged potatoes were taken, cleaned with clean water, and the outer skin of the potatoes was removed by a peeling machine.

[0045] Soak the peeled potatoes in water and cut them into potato pieces of 3cm×3cm×5cm.

[0046] Take 600g of raw materials, and use a wall breaker to crush the potatoes into potato pulp, with an average particle size of 53±2μm.

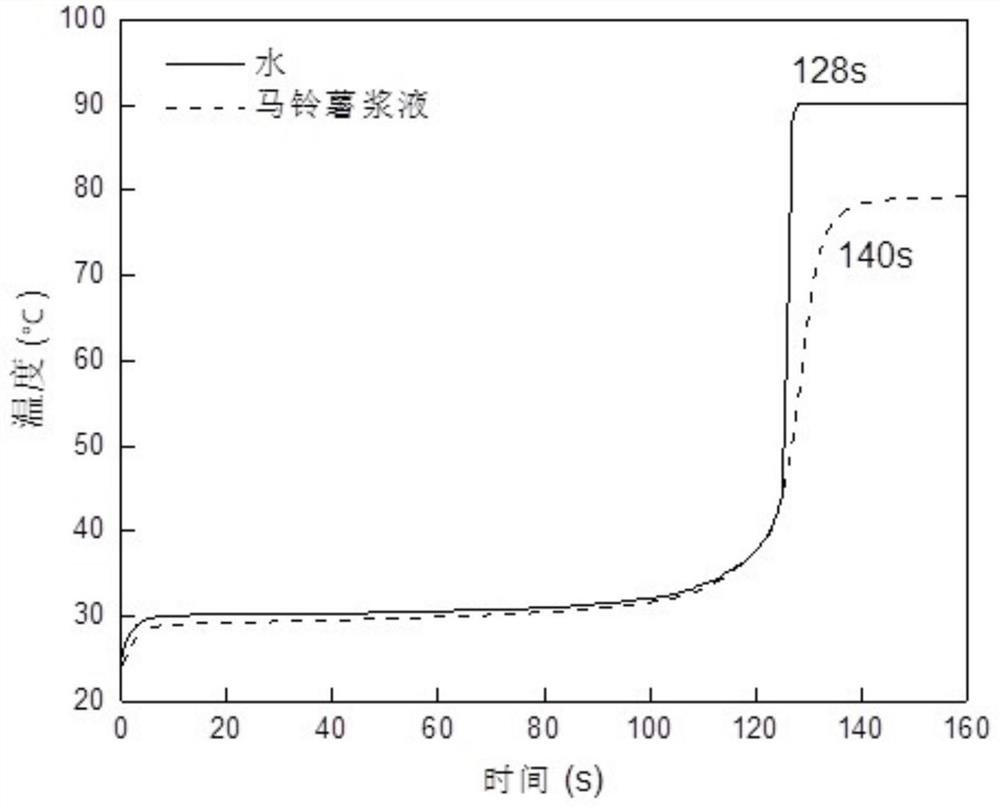

[0047] (2) Cut off the air, pass the potato pulp into the JH-6000DS small-scale spray dryer, set the inlet temperature to 180±1°C, and the outlet temperature to 90±1°C to obtain potato flour.

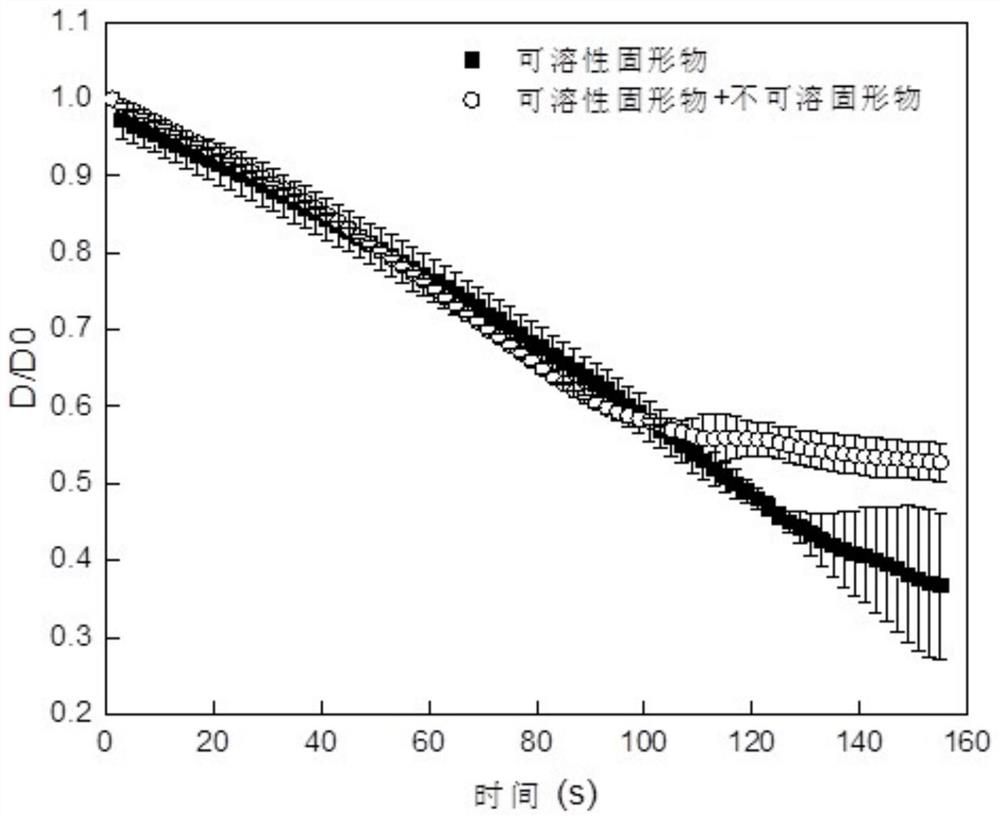

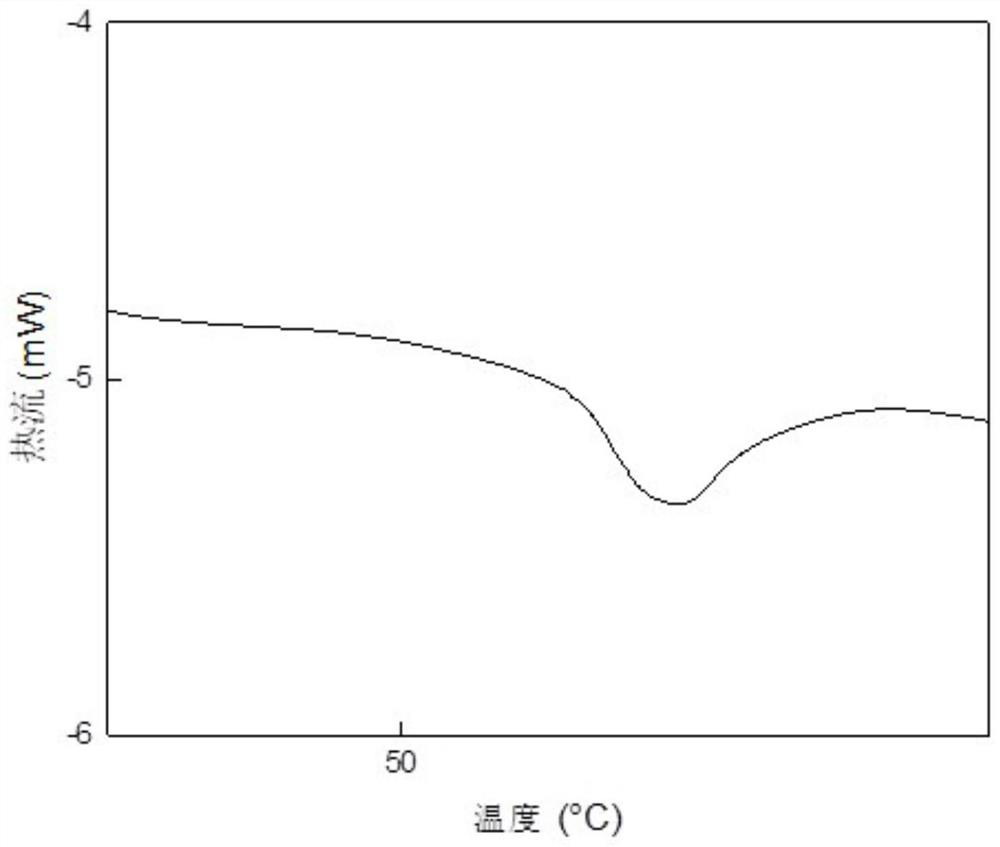

[0048] The obtained potato powder samples were detected, and the result was that the PPO activity was 0.22±0.03; the DSC curve was measured to verify its low gelatinization degree. That is, raw potato powder with low PPO ac...

Embodiment 2

[0049] The preparation of embodiment 2 potato flour

[0050] Proceed as follows:

[0051] (1) Using "Charlotte" as raw material, take pure, ripe and fresh potatoes, wash them with a potato washing machine, and remove the outer skin with a peeling machine.

[0052] Soak the peeled potatoes in water and cut them into random sized potato pieces.

[0053] Potatoes are crushed into potato pulp with a combination of pulverizer and colloid mill, with an average particle size of 45±3 μm.

[0054] (2) Pass the air-isolated potato pulp directly into a small spray dryer, set the inlet temperature to 220±1°C, and the outlet temperature to 110±1°C to prepare potato flour.

[0055] The obtained potato powder samples were detected, and the result was that the PPO activity was 0.36±0.01; the DSC curve was measured to verify its low gelatinization degree. That is, raw potato powder with low PPO activity and low degree of gelatinization was successfully prepared.

Embodiment 3-6

[0056] The preparation of embodiment 3-6 potato powder

[0057] Proceed as follows:

[0058] (1) Take "Feverita" with a dry matter content of 18% as raw material, take fresh, regular-shaped, disease-free and mechanically damaged potatoes, wash them with clean water, and use a peeling machine to remove the outer skin of the potatoes.

[0059] Soak the peeled potatoes in water and cut them into random sized potato pieces.

[0060] Take 4 parts of raw materials, 600g each, and use a wall breaking machine to crush the potatoes into potato pulp, with an average particle size of 47±2μm.

[0061] Add distilled water to each portion of potato pulp, adjust the dry matter content of potato pulp to (A) 10%, (B) 12%, (C) 15%, (D) 18%, and seal and stir.

[0062] (2) Cut off the air, respectively feed the potato pulp into a small spray dryer, set the inlet temperature to 180±1° C., and the outlet temperature to 90±1° C. to obtain the whole potato powder described in Examples 3-6.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com