Lubricating agent for drilling fluid as well as preparation method and application of lubricating agent

A drilling fluid and lubricant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance, high foaming rate, and poor lubrication effect of drilling fluid lubricants, reducing direct contact Small area, particle size, the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

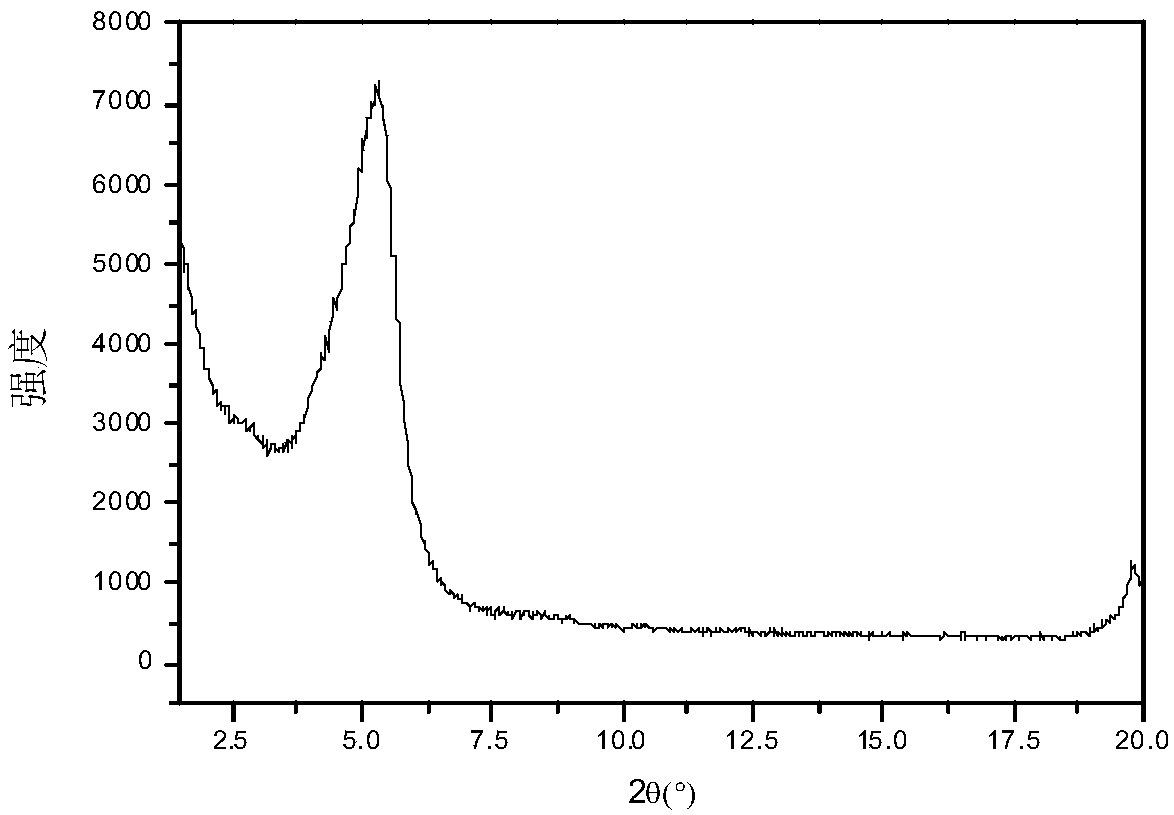

[0055] The preparation method of the nano-inorganic intermediate of the present embodiment is as follows:

[0056] a) Mix phyllosilicate and water to obtain the second mixture, adjust the pH of the second mixture to 1 with 1mol / L hydrochloric acid solution, heat and stir the second mixture to 75°C, keep warm and keep stirring for 30-40min to obtain Activated silicate intermediates;

[0057] Among them, the mass ratio of silicate to water is 1:20;

[0058] b) adding sodium cetyl sulfonate intercalation agent to the activated silicate intermediate, maintaining 75°C and stirring at 30 Hz for 11 hours to obtain an intercalation reaction system;

[0059] Among them, the mass ratio of the activated silicate intermediate to the sodium hexadecylsulfonate intercalation agent is 1:0.1;

[0060] c) Filtrating the intercalation reaction system, washing with deionized water several times, drying at 60°C for 24 hours, grinding and passing through a 200-mesh sieve to obtain the nano inorga...

Embodiment 2

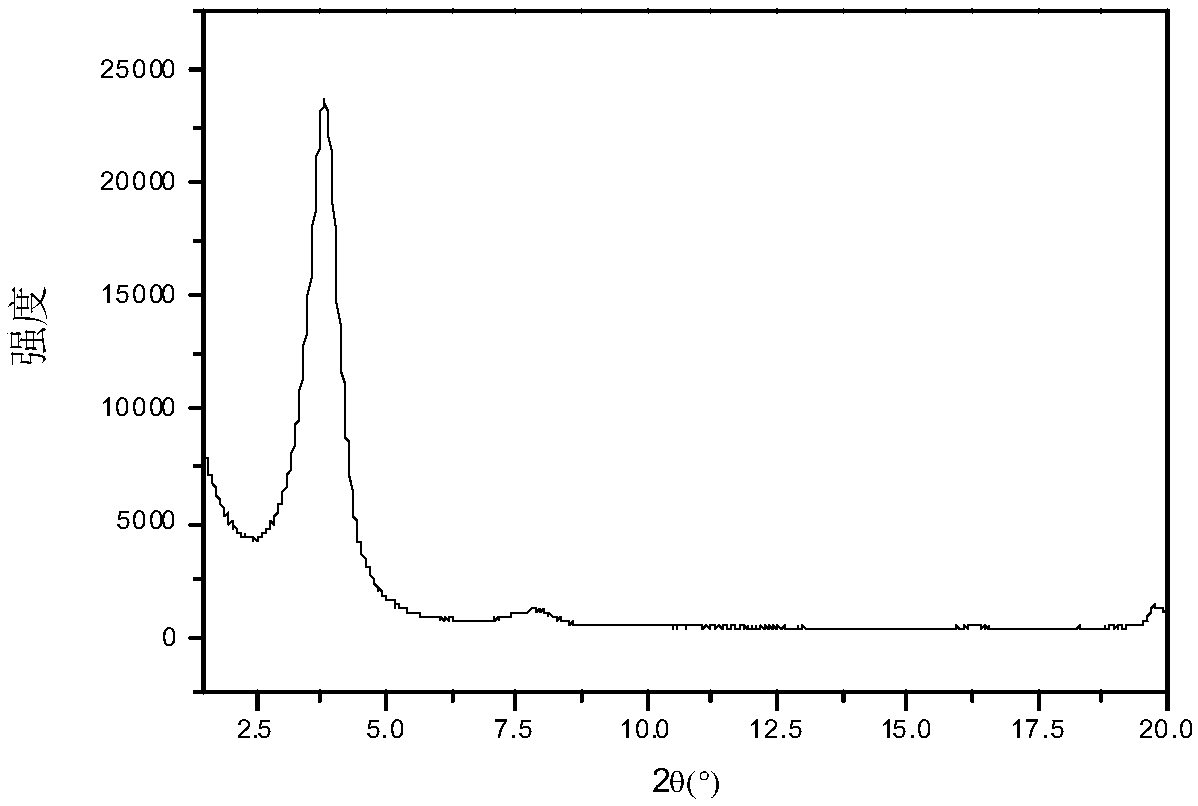

[0063] The preparation method of the nano-inorganic intermediate of the present embodiment is as follows:

[0064] a) Mix phyllosilicate and water to obtain the second mixture, adjust the pH of the second mixture to 1 with 1mol / L hydrochloric acid solution, heat and stir the second mixture to 75°C, keep warm and keep stirring for 30-40min to obtain Activated silicate intermediates;

[0065] Among them, the mass ratio of silicate to water is 1:20;

[0066] b) adding sodium cetyl sulfonate intercalation agent to the activated silicate intermediate, maintaining 75°C and stirring at 30 Hz for 11 hours to obtain an intercalation reaction system;

[0067] Among them, the mass ratio of the activated silicate intermediate to the sodium hexadecylsulfonate intercalation agent is 1:0.19;

[0068] c) Filtrating the intercalation reaction system, washing with deionized water several times, drying at 60°C for 24 hours, grinding and passing through a 200-mesh sieve to obtain the nano inorg...

Embodiment 3

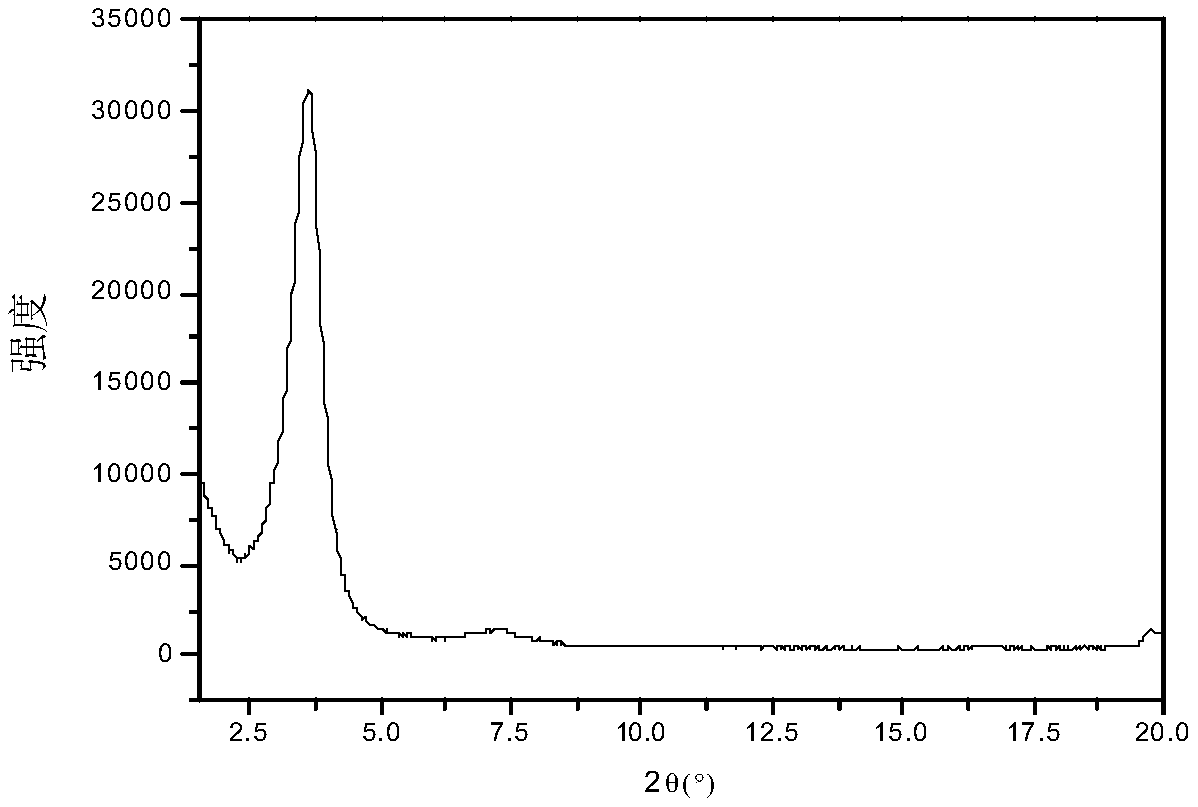

[0071] The preparation method of the nano-inorganic intermediate of the present embodiment is as follows:

[0072] a) Mix phyllosilicate and water to obtain the second mixture, adjust the pH of the second mixture to 1 with 1mol / L hydrochloric acid solution, heat and stir the second mixture to 75°C, keep warm and keep stirring for 30-40min to obtain Activated silicate intermediates;

[0073] Among them, the mass ratio of silicate to water is 1:20;

[0074] b) adding sodium cetyl sulfonate intercalation agent to the activated silicate intermediate, maintaining 75°C and stirring at 30 Hz for 11 hours to obtain an intercalation reaction system;

[0075] Among them, the mass ratio of the activated silicate intermediate to the sodium hexadecylsulfonate intercalation agent is 1:0.27;

[0076] c) Filtrating the intercalation reaction system, washing with deionized water several times, drying at 60°C for 24 hours, grinding and passing through a 200-mesh sieve to obtain the nano inorg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com