Fiber laser convenient to generate high repetition frequency pulse laser light

A fiber laser, high repetition rate technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems that the full polarization-maintaining system cannot be fully utilized, and there is no application of polarization-maintaining fiber, and achieves simple structure and lock Unique mold point, anti-instability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

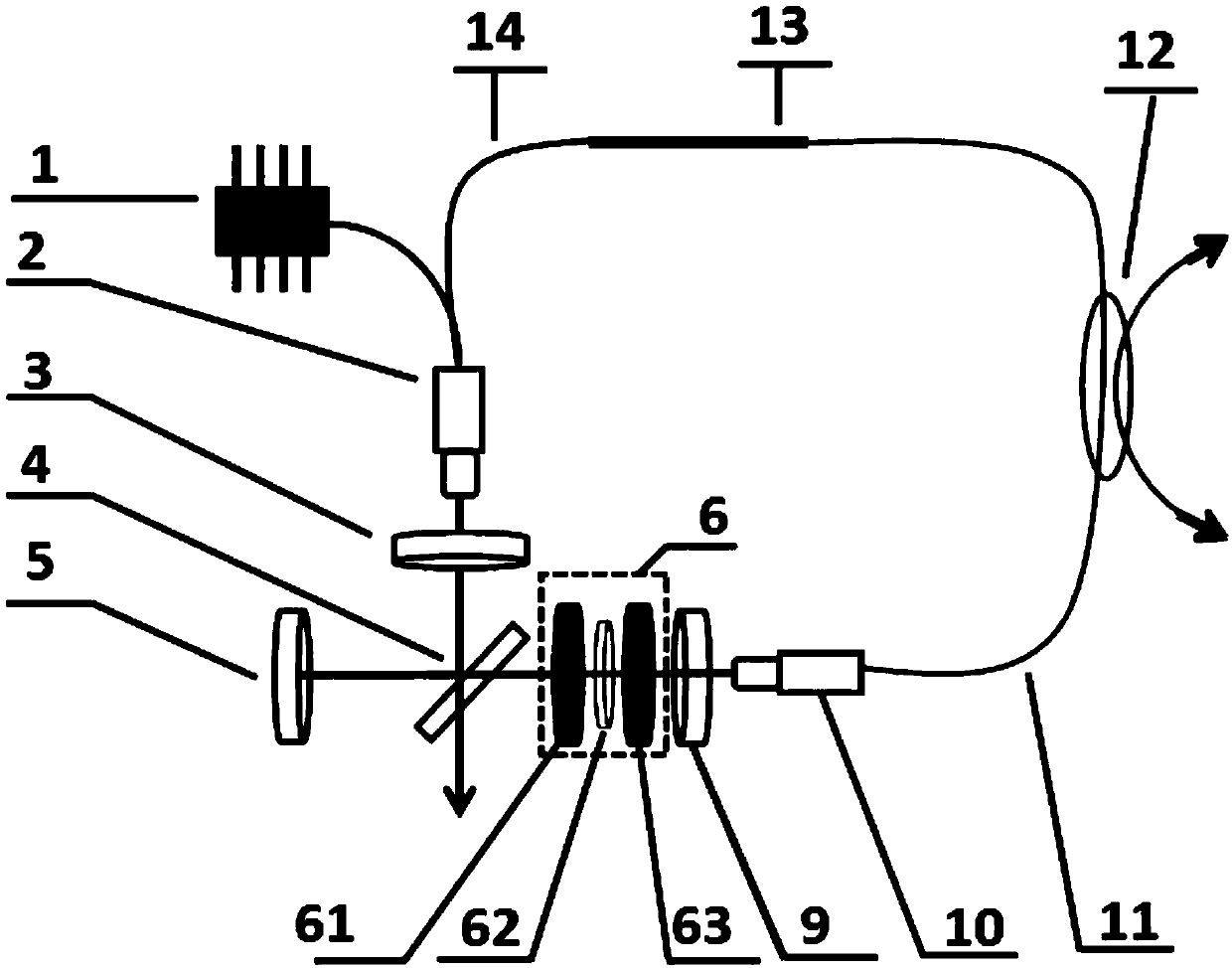

[0027] Example 1, such as figure 1 As shown, during specific implementation, the phase shifter unit 6 adopts a linear phase shifter, which includes a first Faraday rotator 61, a 1 / 4 wave plate 62, and a second Faraday rotator 63. The first Faraday rotator Mirror 5, first beam splitter 4, first Faraday rotator 61, 1 / 4 wave plate 62, second Faraday rotator 63, second 1 / 2 wave plate 9, second fiber collimator 10 The straight outlets are arranged in a straight line in turn.

[0028] As mentioned above, during specific implementation, the first wavelength division multiplexing collimation unit 2 adopts a wavelength division multiplexing collimator.

[0029] As mentioned above, during operation, the first pumping source 1 couples the pumping light into the cavity through the first wavelength division multiplexing collimation unit 2, and by increasing the pumping power above the threshold of the fiber laser, the laser Oscillation occurs; the polarization state output by the first w...

Embodiment 2

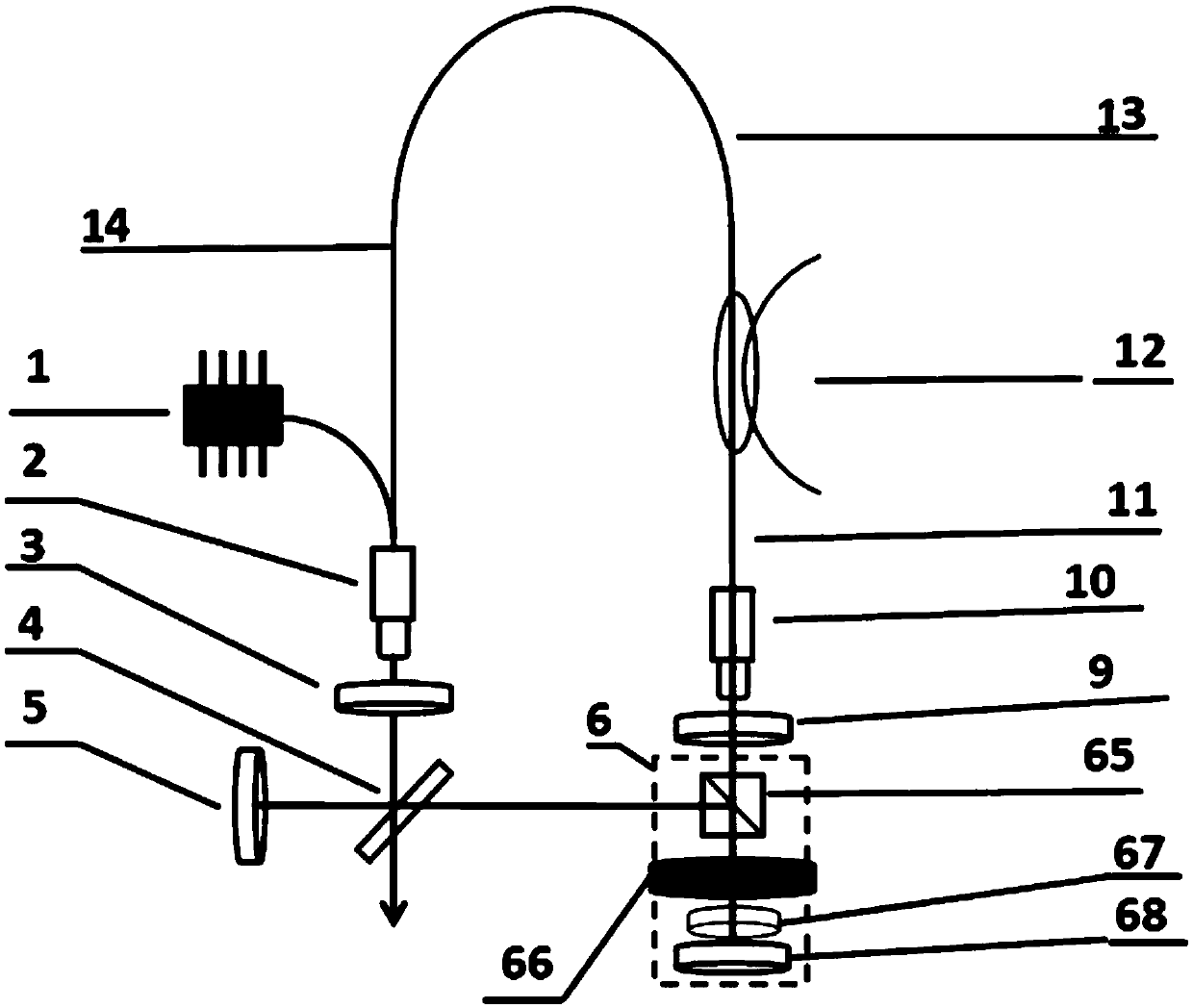

[0033] Example 2, such as figure 2 As shown, during specific implementation, the phase shifter unit 6 adopts a reflective phase shifter, which includes a polarization beam splitter cube 65, a third Faraday rotator 66, a 1 / 8 wave plate 67, and a second mirror 68 , the first reflector 5, the first beam splitter 4, and the polarization beam splitter cube 65 are arranged linearly in sequence, and the second reflector 68, the 1 / 8 wave plate 67, the third Faraday rotator 66, the polarization beam splitter The cube 65, the second 1 / 2 wave plate 9, and the collimated output ends of the second fiber collimator 10 are arranged in a straight line in sequence.

[0034] As mentioned above, during specific implementation, the first wavelength division multiplexing collimation unit 2 adopts a wavelength division multiplexing collimator.

[0035] As mentioned above, during operation, the first pumping source 1 couples the pumping light into the cavity through the first wavelength division m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com