Duck fatty liver microcapsule and preparation method thereof

A technology of duck fat liver and microcapsules is applied in the directions of ultrasonic treatment of food, function of food ingredients, and food forming, etc. It can solve problems such as high tensile strength, achieve good film-forming properties, widen the utilization market of duck fat liver, Improve the effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of duck fat liver microcapsules of the present invention comprises the following steps:

[0030] 1) Preparation of core material duck fatty liver slurry: homogenate duck fatty liver to obtain slurry. The composition of the slurry is relatively complex. In addition to oil, it also contains liver cell tissue, blood vessels, capillary ducts, hoof tissue, etc. in different proportions. It is difficult to ensure the consistency of particle shape and size after pulping; Unlike the affinity of substances, it is difficult to implement microencapsulation. Different from the foie gras oil studied before, because the ingredients are single, as long as the ratio of the core material to the wall material is selected, it is easier to coat and the particle size is relatively consistent.

[0031] 2) Wall material selection: Arabic tape is negatively charged; gelatin is an amphoteric polymer polyelectrolyte, which is positively charged under acidic conditions and...

Embodiment 1

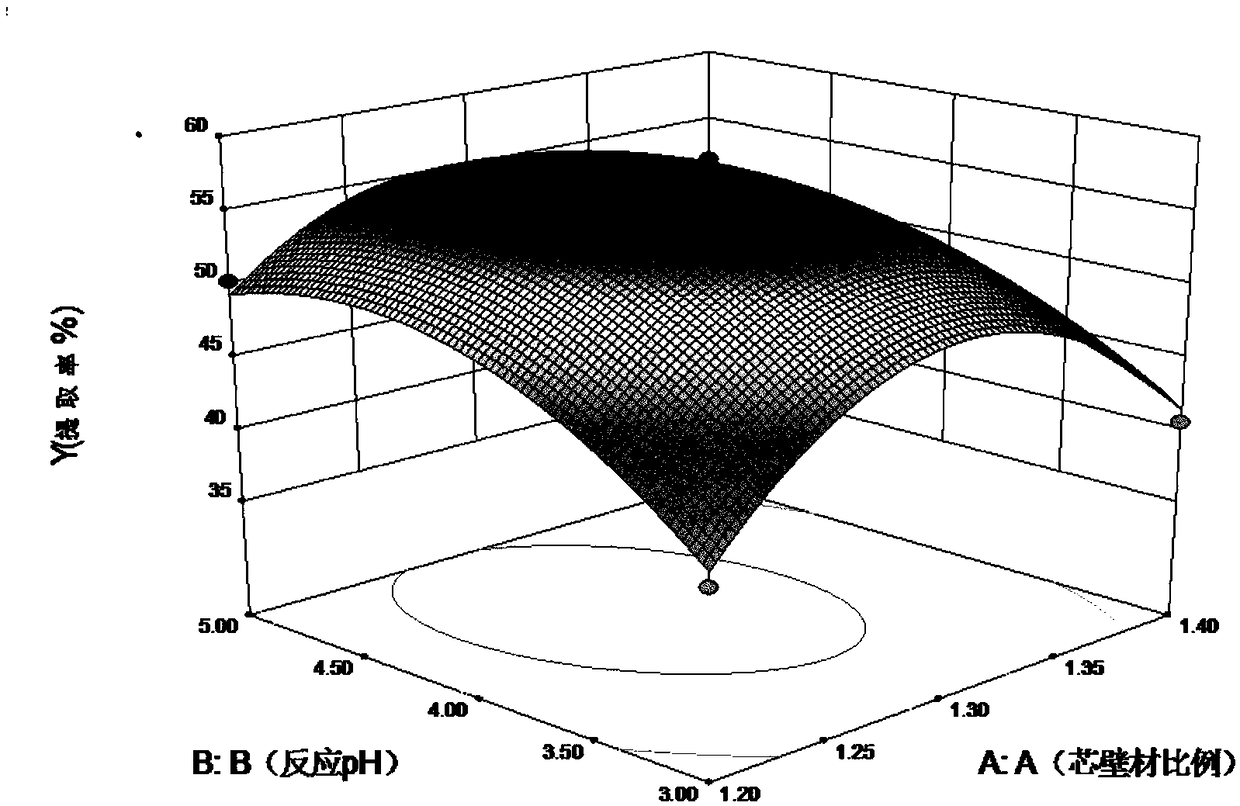

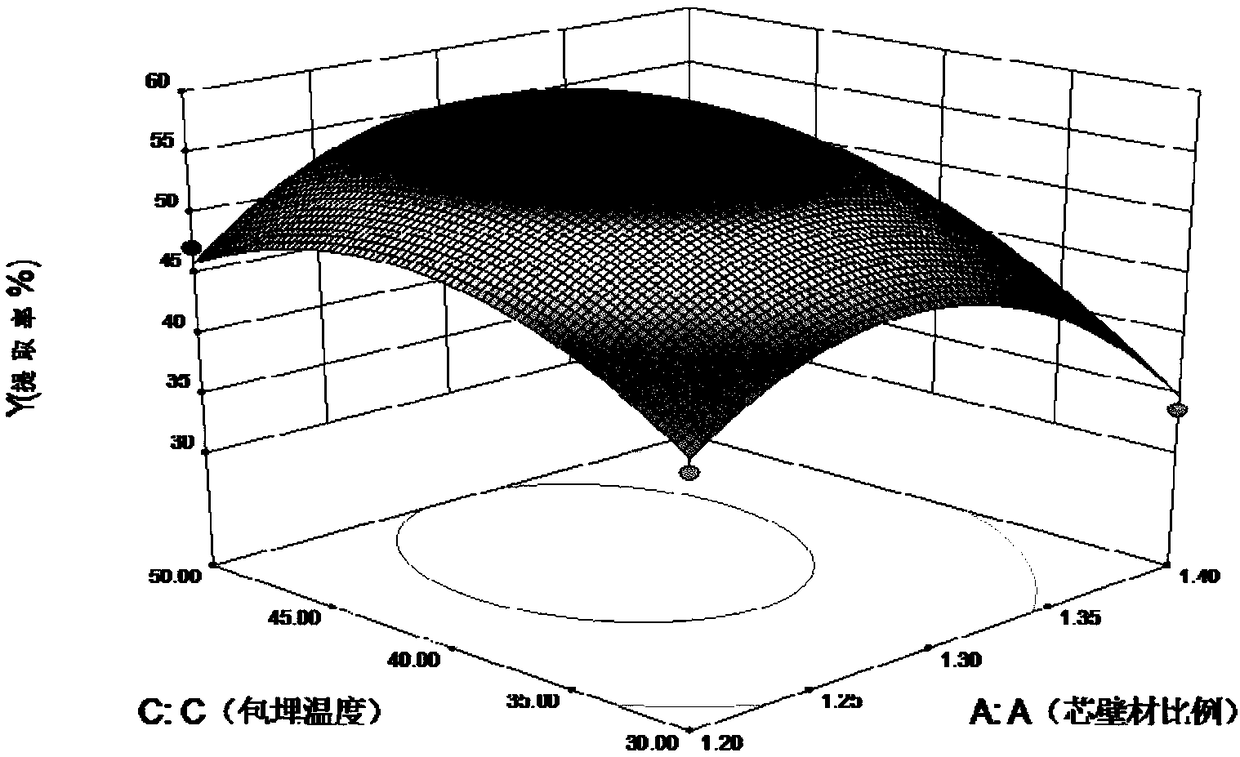

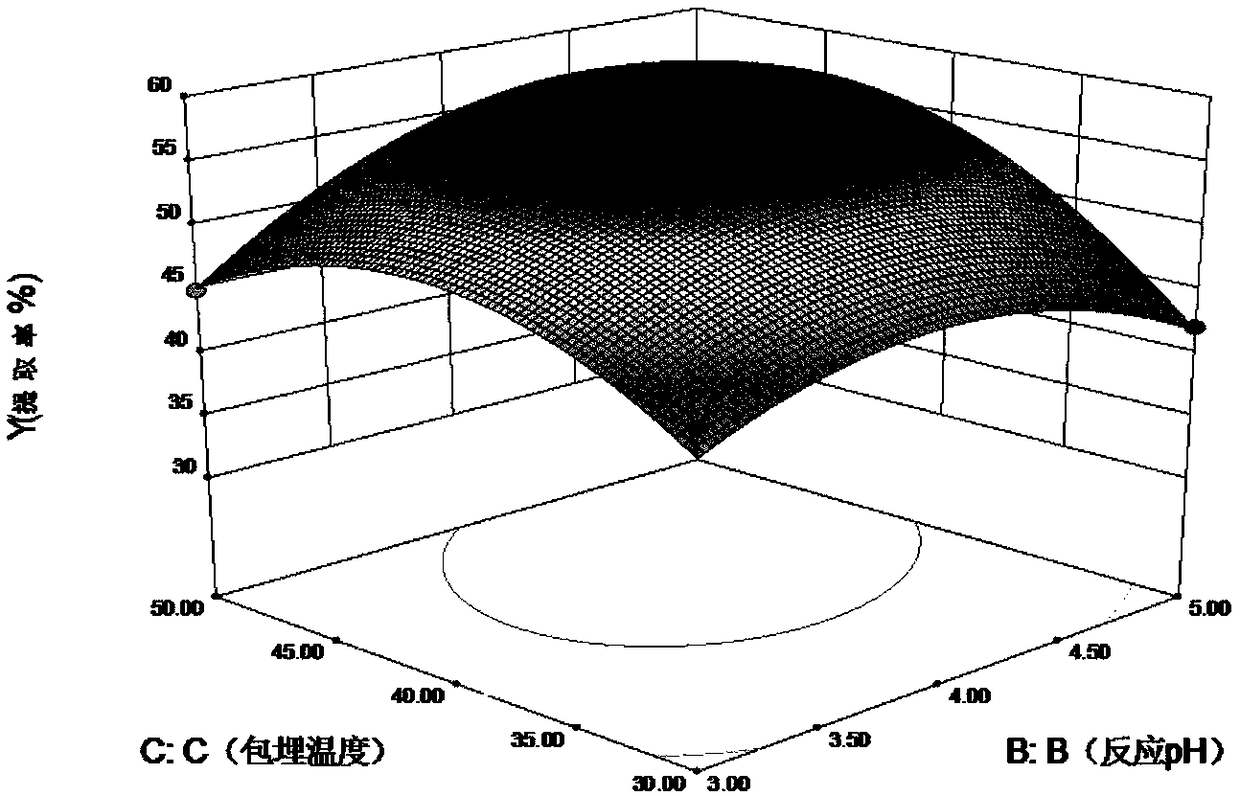

[0038] Example 1: Screening test of duck fat liver microencapsulation process conditions

[0039] (1) Preparation of emulsion

[0040] Prepare gum arabic and gelatin into an aqueous solution of a certain concentration, and after fully dissolving and mixing, add a certain amount of alkyl glycoside (APG) and chitosan, stir until uniform, and use this solution as a reaction solution; Add it dropwise to the reaction solution, adjust the pH with acetic acid, and use ultrasonic treatment to form an emulsion.

[0041] (2) Emulsion freeze-drying treatment

[0042] Pour the emulsion into a plastic petri dish, pre-cool at -40°C, freeze-dry it in a freeze dryer for 15 hours, and take it out.

[0043] (3) Determination of Microcapsule Embedding Rate

[0044] The embedding rate refers to the ratio of the content of duck fatty liver serum embedded in the microcapsule product to the total amount of duck fatty liver serum added during embedding. The higher the embedding rate, the greater ...

Embodiment 2

[0071] Embodiment 2: comparative test 1 of preparation technology of duck fat liver microcapsules

[0072] The emulsion was prepared according to the steps of Example 1, and maltodextrin and soybean protein isolate were selected as the coating wall material, wherein the ratio of the core material to the wall material was 1:5, the reaction pH value was 5.0, and the wall reaction temperature was 60°C. Add emulsifier alkyl glucoside and ultrasonic treatment to form emulsion. The emulsion was freeze-dried, and the microcapsule embedding rate was measured according to the above method. After five repeated tests, the embedding rate of the microcapsule products obtained was 56.21%, 57.34%, 56.31%, 56.43%, and 57.91%. , are lower than the embedding rate of 58.79% in Example 1, show that maltodextrin and soybean protein isolate are used as wall materials to coat duck fat liver powder effect than gelatin and acacia gum as wall materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com