Method for removing dust thionazin in petroleum smelting chimney

A technology for oil smelting and chimneys, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., and can solve problems such as clogging of filter plates, excessive dust concentration in workplaces, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

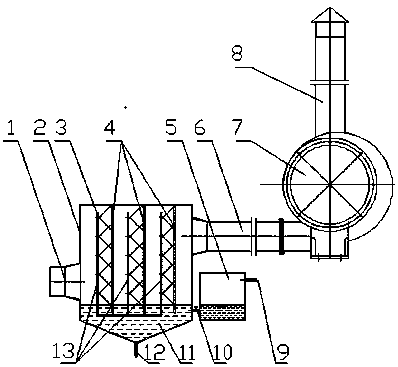

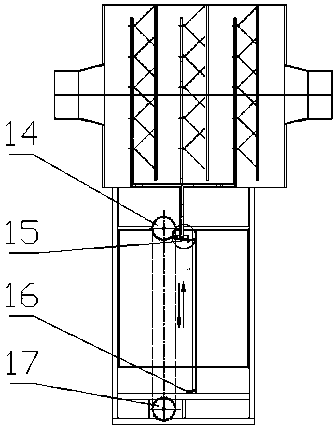

[0026] The technical solution adopted by the present invention to solve the technical problem is characterized in that: the method for removing dust sulfur and phosphorus in the chimney of petroleum smelting consists of an inlet and outlet water balance system, a cantilever-type filter plate high-pressure flushing pipe, a high-pressure water circulation water supply system, and a mechanical transmission system. , electrical control system, wastewater collection sedimentation tank.

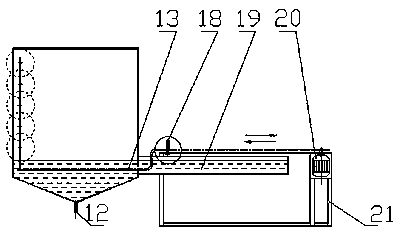

[0027] The method for removing dust sulfur and phosphorus in the chimney of petroleum smelting is characterized in that: the inlet and outlet water balance system is composed of the blowdown valve 12 at the bottom of the smoke filter chamber 2, the supply water tank A, the smoke filter room 2, the supply water tank A and the communication valve 10, etc. Composition, the cleaning wastewater is discharged into the sedimentation tank through the bottom drain valve 12 of the soot filter chamber 2.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com