A kind of intelligent grinding system control method

A control method and grinding technology, applied in grain processing, etc., can solve problems such as energy waste, heavy host load, and large current loss, and achieve the effects of reducing production costs, reducing operating weight, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

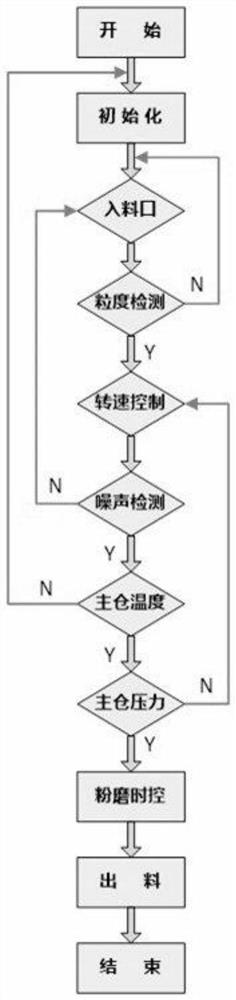

[0018] see figure 1 A preferred embodiment of an intelligent grinding system control method. In this embodiment, the method firstly transforms the grinding machine and related equipment. All of them are equipped with online particle size detectors to detect the particle size parameters of the incoming and outgoing grinding mills, and at the same time transmit the parameters to the main controller according to the set time period, and the main controller adjusts the running state of the pulverizer according to the parameters.

[0019] The transformation of the host control area includes:

[0020] ① Install a material level sensor in the raw material warehouse, the main controller can monitor the warehouse position instead of the manual warehouse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com