Flower-shaped AgPd nanometer alloy and preparing and using method

A nano-alloy, flower-like technology, applied in chemical instruments and methods, nanotechnology, metal processing equipment, etc., can solve the problems of high cost, insignificant Pd-M alloying effect, and insufficient electrocatalytic activity, and achieve catalytic Increased activity, excellent catalytic activity and stability, avoiding the effect of high temperature calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

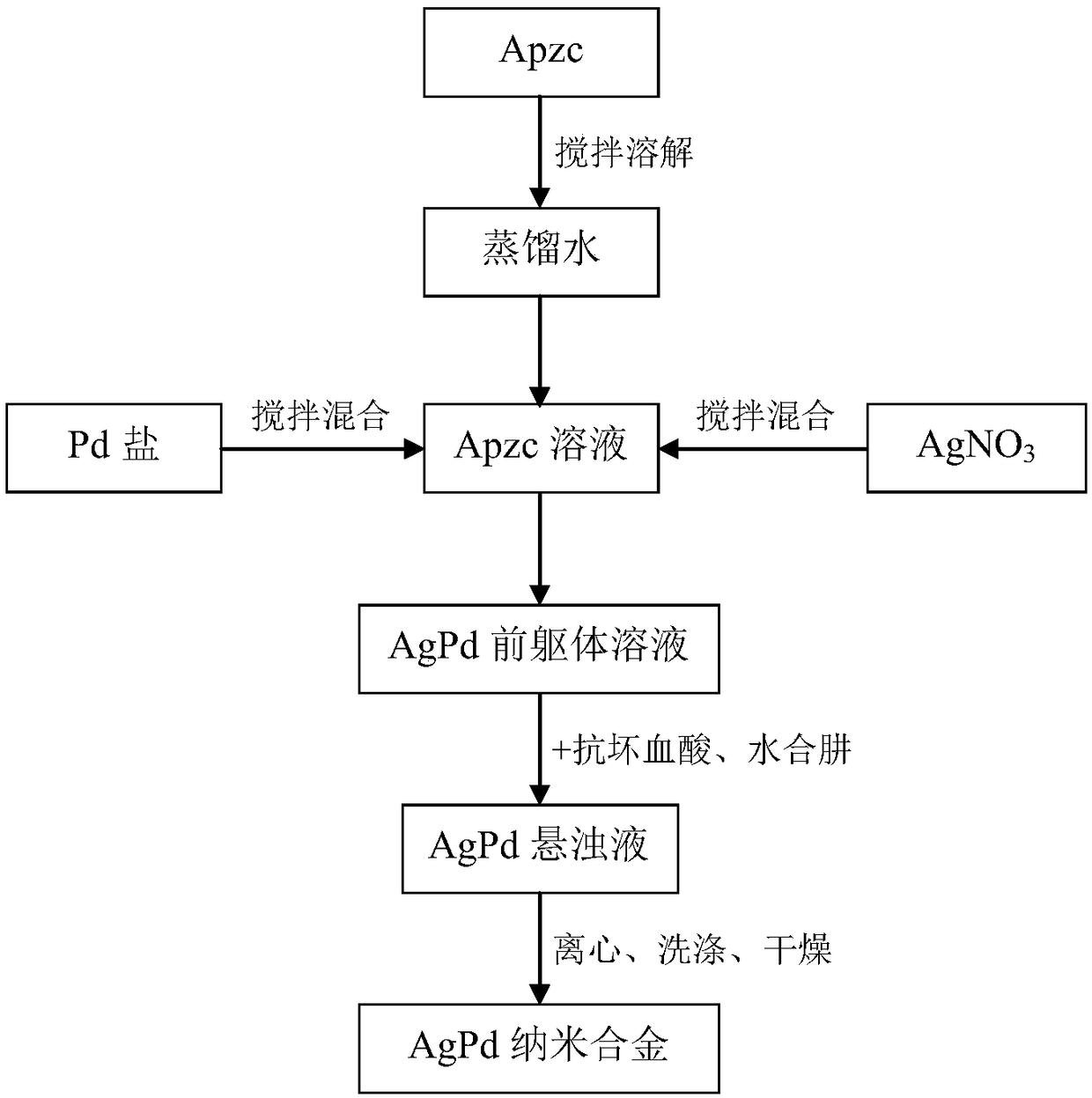

Method used

Image

Examples

Embodiment 1

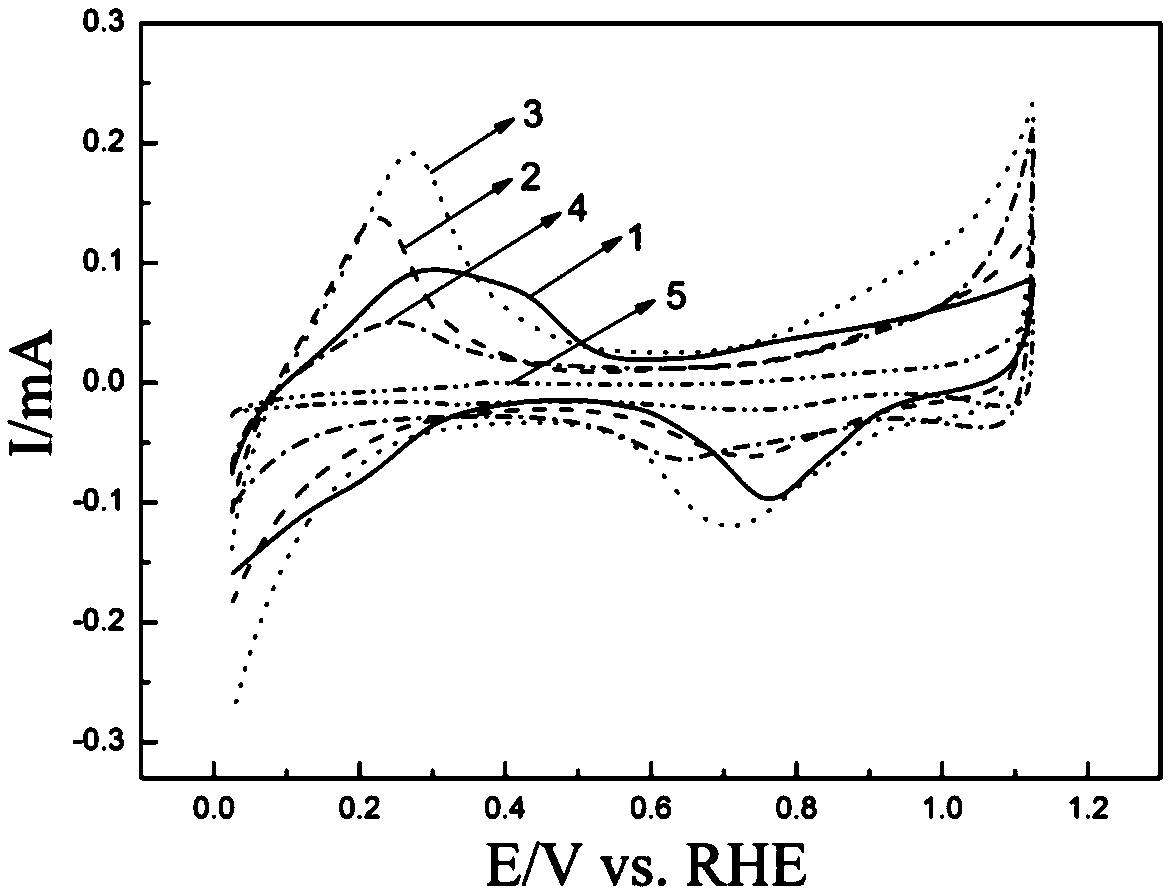

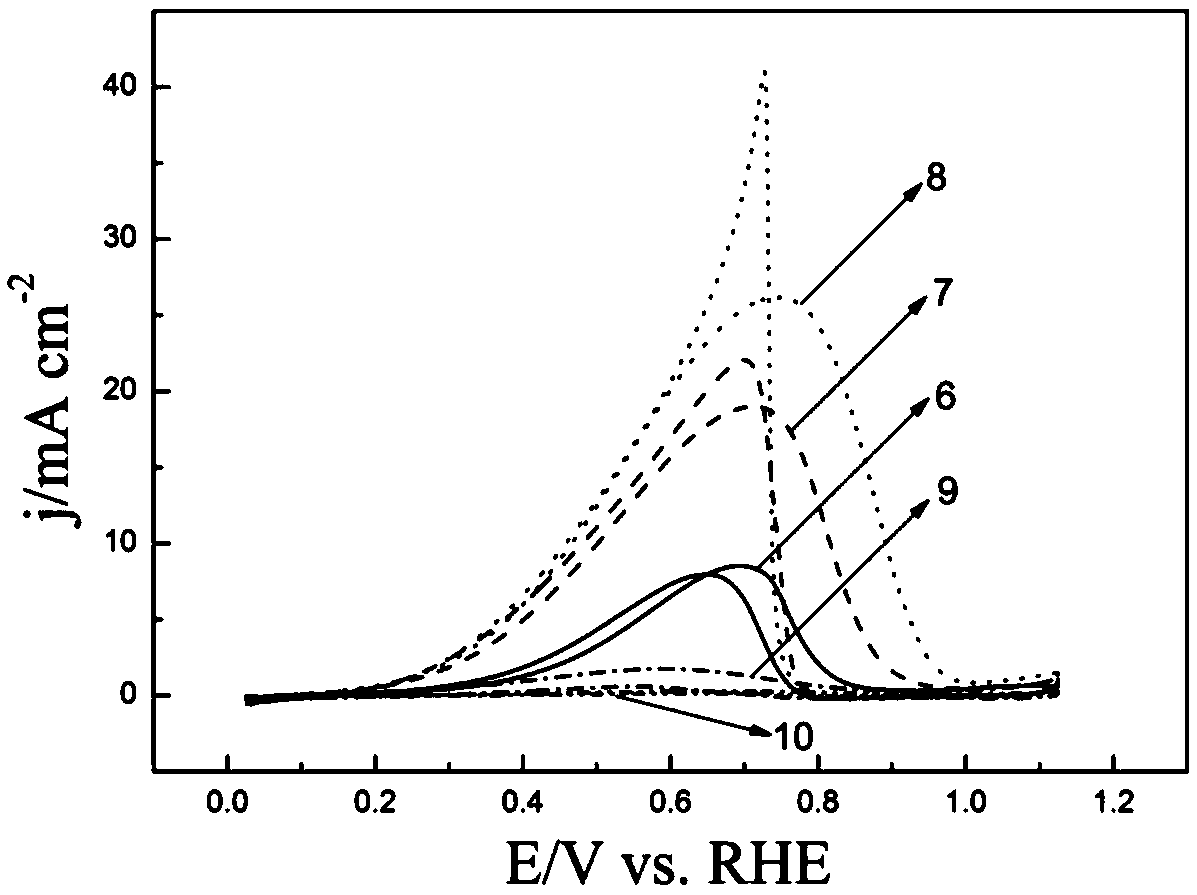

[0057] This embodiment is a pure Pd catalyst. The electrochemical specific surface area of the pure Pd catalyst is 4.64 m 2 / g, the current density can reach 8.52mA / cm at 0.69Vvs.RHE 2 . Under simulated sunlight, the oxidation peak current of pure Pd catalyst is from 8.52mA / cm 2 Increase to 9.11mA / cm 2 . The preparation process of this embodiment is as follows:

[0058] (1) Weigh 0.0348 g of Apzc into 6.9 mL of distilled water, stir magnetically until it is fully dissolved. Then add 2mL Na to the stirring Apzc solution 2 PdCl 4 (20mmol / L), magnetically stirred at room temperature for 5 min. Wherein the concentration of Apzc is 25mmol / L, Na 2 PdCl 4 The concentration is 4mmol / L.

[0059] (2) Quickly inject 1 mL of ascorbic acid solution (0.1 mol / L) into the precursor solution obtained in step (1), and stir and react for 1 hour at room temperature. Then 0.1 mL of hydrazine hydrate (80 wt%) was added, and the reaction was continued to stir for 30 min.

[0060] (3) Centrifugal sepa...

Embodiment 2

[0064] This embodiment is an Ag 25 Pd 75 Nano alloy catalyst, Ag 25 Pd 75 The content of silver in the nano-alloy catalyst is 26%, and the content of palladium is 74%, and the percentages are atomic percentages. Ag 25 Pd 75 The electrochemical specific surface area of the nano-alloy catalyst is 3.79m 2 / g, the current density at 0.71V vs. RHE is 18.98mA / cm 2 . The preparation process of this embodiment is as follows:

[0065] (1) Weigh 0.0348 g of Apzc into 6.9 mL of distilled water, stir magnetically until it is fully dissolved. Then add 1.5mL Na to the stirring Apzc solution 2 PdCl 4 (20mmol / L) and 0.5mL AgNO 3 (20mmol / L), magnetically stirred at room temperature for 5 min. Wherein, the concentration of Apzc is 25mmol / L, Na 2 PdCl 4 The concentration is 3mmol / L, AgNO 3 The concentration is 1mmol / L.

[0066] (2) Quickly inject 1 mL of ascorbic acid solution (0.1 mol / L) into the precursor solution obtained in step (1), and stir and react for 1 hour at room temperature. Then 0....

Embodiment 3

[0071] This embodiment is an Ag 50 Pd 50 Nano alloy catalyst, Ag 50 Pd 50 The average particle size of the nano-alloy catalyst is 320nm, the dispersion is good, the morphology is flower-like, Ag 50 Pd 50 The content of silver in the nano-alloy catalyst is 51%, and the content of palladium is 49%, and the percentages are atomic percentages. Ag 25 Pd 75 The electrochemical specific surface area of the nano-alloy catalyst is 10.37m 2 / g, the current density at 0.74V vs. RHE is 26.16mA / cm 2 . Under simulated sunlight, Ag 50 Pd 50 The oxidation peak current of the nano-alloy catalyst is from 26.16mA / cm 2 Increase to 30.97mA / cm 2 . The preparation process of this embodiment is as follows:

[0072] (1) Weigh 0.0348 g of Apzc into 6.9 mL of distilled water, stir magnetically until it is fully dissolved. Then add 1mL Na to the stirring Apzc solution 2 PdCl 4 (20mmol / L) and 1mL AgNO 3 (20mmol / L), magnetically stirred at room temperature for 5 min. Wherein, the concentration of Apzc is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com