Method for treating methyl violet dye wastewater

A dye wastewater and treatment method technology, which is applied in textile industry wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of unsatisfactory treatment effect of high-concentration printing and dyeing wastewater, slow dye adsorption, low hardness, etc. , to achieve the effect of low cost, improved adsorption treatment, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A treatment method for methyl violet dye wastewater, comprising the following steps:

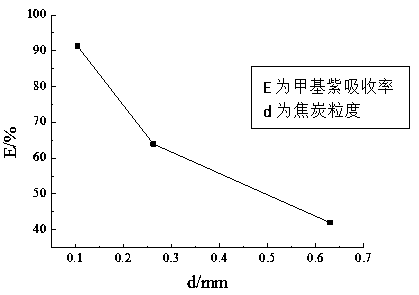

[0029] a) Adsorbent treatment: heat ordinary fresh coke in a water bath at 60°C for 80 minutes, dry at 130°C for 2 hours, and grind to 100 mesh;

[0030] b) Adjust the pH of the methyl violet dye wastewater to 5.5;

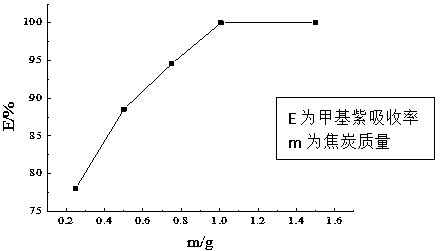

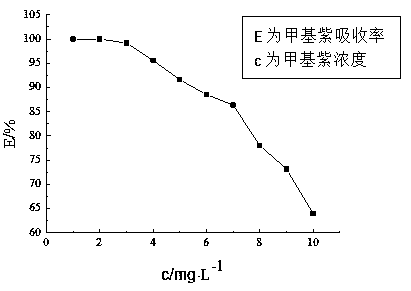

[0031] c) Oscillation: add adsorbent to the pH-adjusted methyl violet dye wastewater, add 1g of adsorbent per 50ml methyl violet dye wastewater; shake for 40min, then let stand for 100min; the concentration of the methyl violet dye wastewater It is 4 mg / L.

Embodiment 2

[0033] A treatment method for methyl violet dye wastewater, comprising the following steps:

[0034] a) Adsorbent treatment: heat the coke in a water bath at 80°C for 60 minutes, dry it at 130°C for 2 hours, and then grind it to 120 mesh;

[0035] b) Adjust the pH of the methyl violet dye wastewater to 6.5;

[0036] c) Oscillation: add adsorbent to the pH-adjusted methyl violet dye wastewater, add 1g of adsorbent per 60ml of methyl violet dye wastewater; shake for 30min, then let stand for 90min; the concentration of the methyl violet dye wastewater It is 2 mg / L.

Embodiment 3

[0038] A treatment method for methyl violet dye wastewater, comprising the following steps:

[0039] a) Adsorbent treatment: heat the coke in a water bath at 70°C for 70 minutes, dry it at 130°C for 2 hours, and then grind it to 140 mesh;

[0040] b) Adjust the pH of the methyl violet dye wastewater to 6;

[0041] c) Oscillation: Add 1 g of adsorbent to the methyl violet dye wastewater after pH adjustment, and add 1 g of adsorbent to every 55 ml of methyl violet dye wastewater; after shaking for 30 minutes, let it stand for 90 minutes; the concentration of the methyl violet dye wastewater is 3 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com