Method for preparing water quality stabilizer of circulatory cooling water by utilizing zinc-containing wastewater and application of method

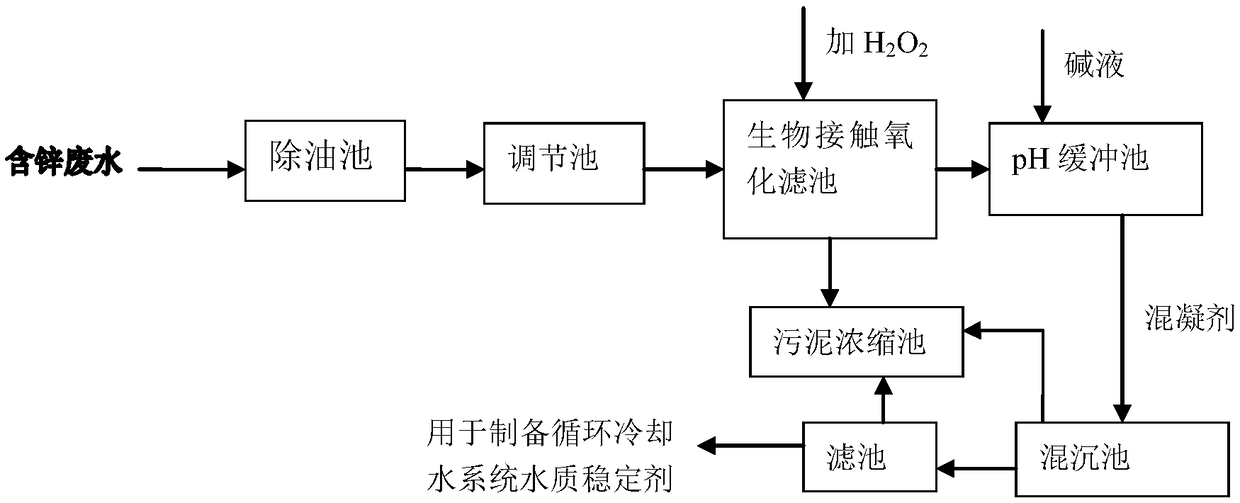

A technology of water quality stabilizer and circulating cooling water, which is applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. It can solve the problem of small amount of treatment by physical and chemical methods, long treatment process, human and animal impact, etc. problems, to achieve resource utilization, easy industrial application, simple and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

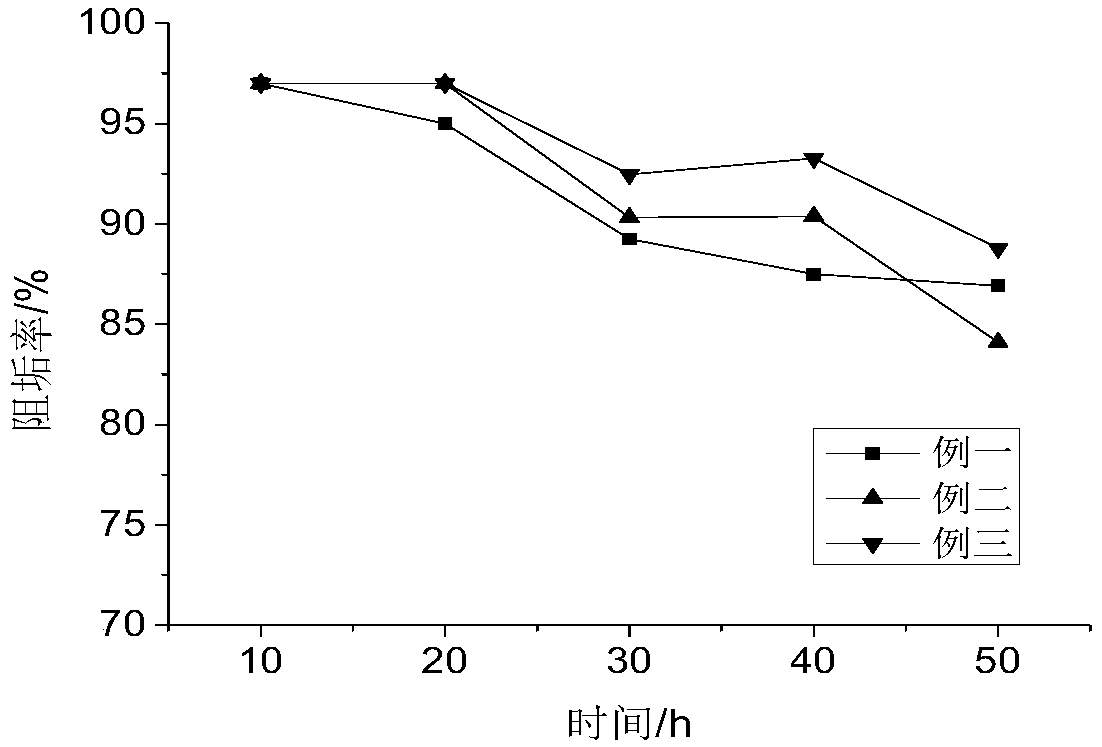

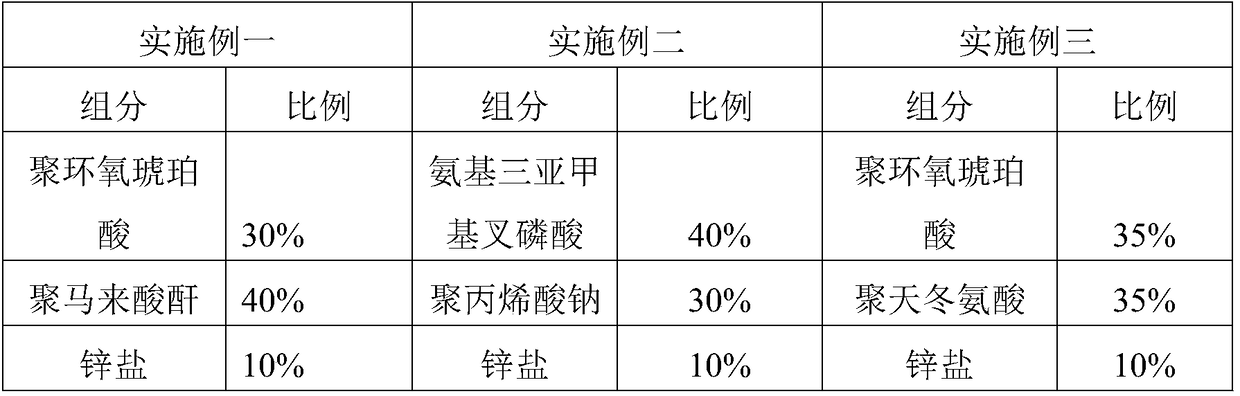

Embodiment 1

[0031] The method for preparing circulating cooling water water quality stabilizer 1 by utilizing zinc-containing waste water comprises the following steps:

[0032] 1) 2L of zinc-containing wastewater generated during the production process of the cold-rolling electro-galvanizing unit is passed into the grease trap, and the gravity separation method is used to stay for 10 minutes to remove suspended oil with a particle size greater than 15 μm;

[0033] 2) The above-mentioned zinc-containing wastewater after degreasing is discharged into the regulating tank, and the hydraulic retention time of the regulating pond is 8min for preliminary settlement and separation;

[0034] 3) Pass the wastewater discharged from the above regulating tank through the biological contact oxidation filter, slowly add 30mL of 30% H in the pool 2 o 2 , the hydraulic retention time in the pool is 30min, and the pH value is 3 to 5, and Fe in the wastewater 2+ Oxidation reaction occurs through interact...

Embodiment 2

[0040] The method for preparing circulating cooling water water quality stabilizer 2 by utilizing zinc-containing waste water comprises the following steps:

[0041]1) 4L of zinc-containing wastewater generated during the production process of the cold-rolling electro-galvanizing unit is passed into the grease trap, and the gravity separation method is used to stay for 10 minutes to remove suspended oil with a particle size greater than 15 μm;

[0042] 2) The above-mentioned zinc-containing wastewater after degreasing is discharged into the regulating tank, and the hydraulic retention time of the regulating pond is 8min for preliminary settlement and separation;

[0043] 3) Pass the waste water discharged from the above-mentioned regulating tank through the biological contact oxidation filter, and slowly add 60 mL of H2O with a mass fraction of 30% in the pool 2 o 2 , the hydraulic retention time in the pool is 30min, and the pH value is 3 to 5, and Fe in the wastewater 2+ O...

Embodiment 3

[0049] The method that utilizes zinc-containing waste water to prepare circulating cooling water water quality stabilizer 3 may further comprise the steps:

[0050] 1) 5L of zinc-containing waste water generated during the production process of the cold-rolling electrogalvanizing unit is passed into the grease trap, and the gravity separation method is used to stay for 10 minutes to remove suspended oil with a particle size greater than 15 μm;

[0051] 2) The above-mentioned zinc-containing wastewater after degreasing is discharged into the regulating tank, and the hydraulic retention time of the regulating pond is 8min for preliminary settlement and separation;

[0052] 3) Pass the waste water discharged from the above regulating tank through the biological contact oxidation filter, and slowly add 80mL of 30% H in the pool. 2 o 2 , the hydraulic retention time in the pool is 30min, and the pH value is 3 to 5, and Fe in the wastewater 2+ Oxidation reaction occurs through int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com