Bi2S3/TiO2 composite nanorod array and preparation method thereof

A nanorod array and composite material technology, which is applied in the field of Bi2S3/TiO2 composite nanorod array and preparation, can solve the problems of easy photolysis and other problems, and achieve the goals of inhibiting photolysis, highlighting photoelectric performance, improving stability and photoelectric performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

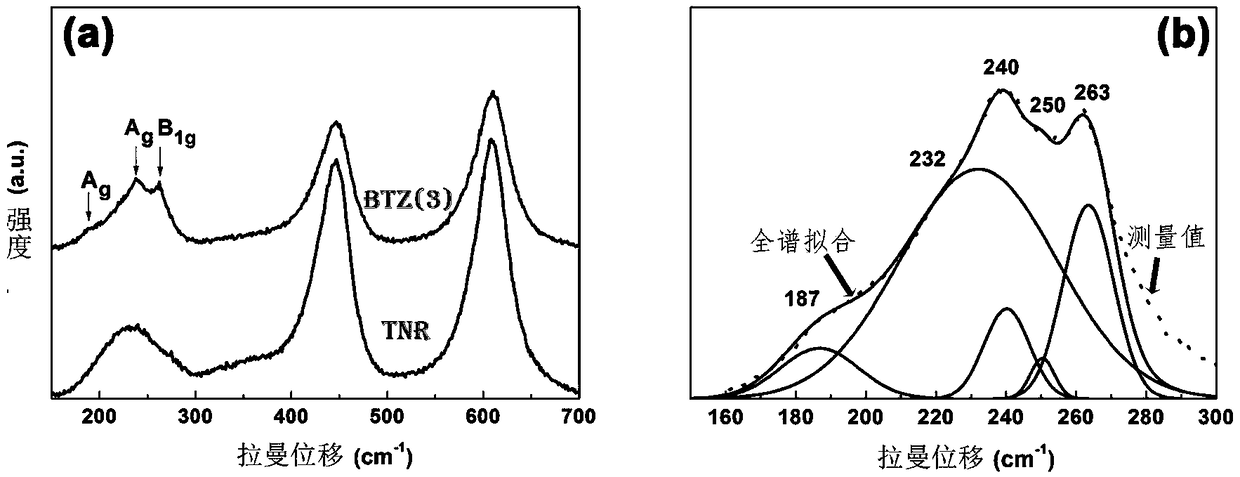

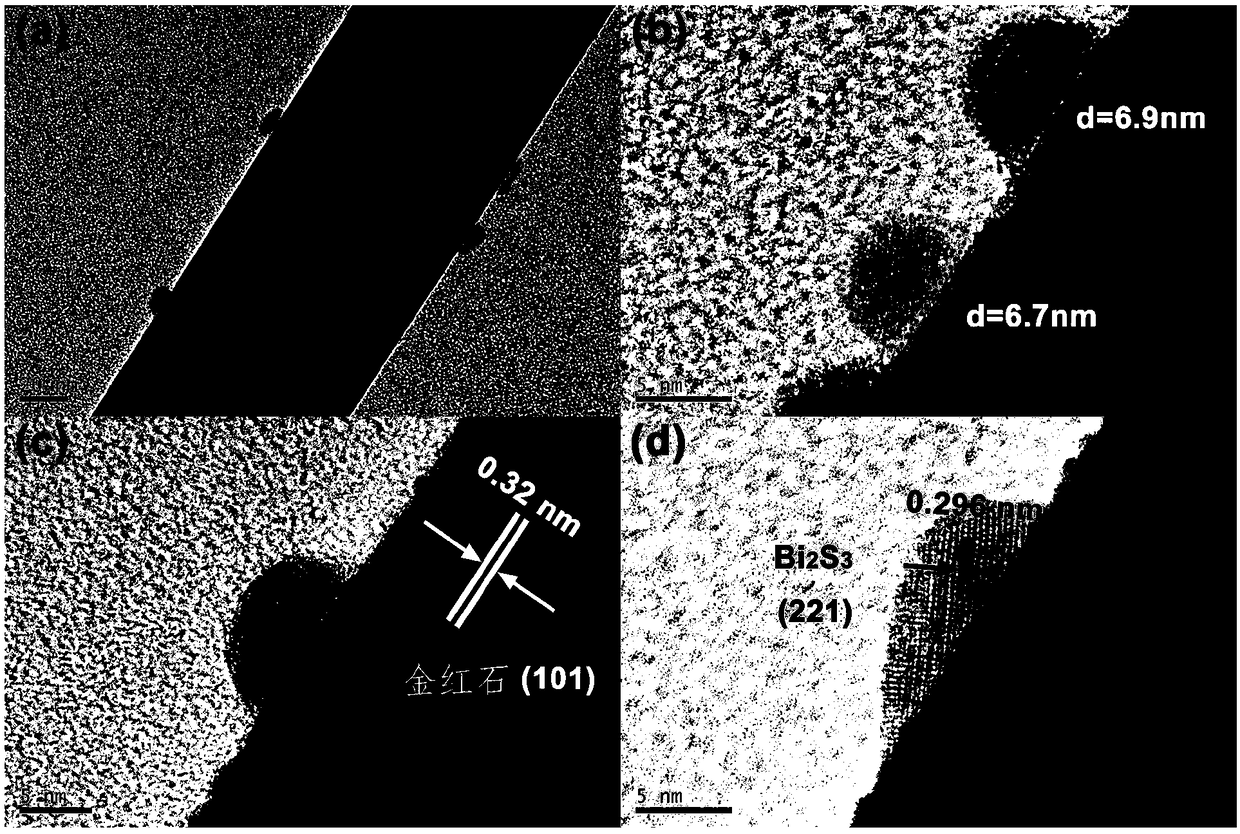

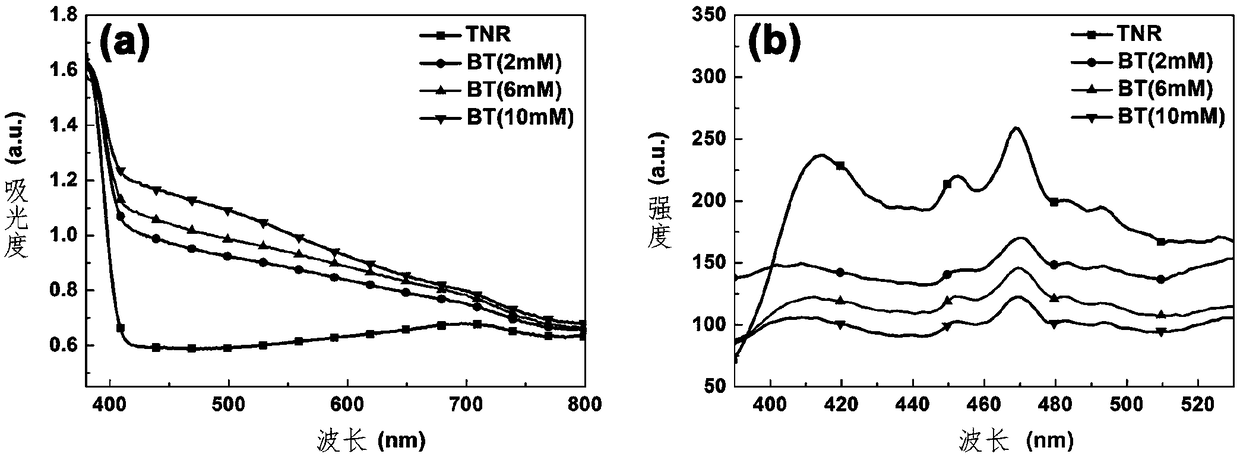

[0022] TiO 2 Nanorod array (TNR) preparation: adding tetrabutyl titanate to hydrochloric acid solution and stirring to obtain a clear solution, the concentration of the hydrochloric acid solution is 18wt%, and the volume ratio of tetrabutyl titanate to hydrochloric acid solution is 1:60 Afterwards, the FTO glass cleaned and dried by acetone, ethanol and deionized water is placed obliquely in the polytetrafluoroethylene liner, the conductive surface of the FTO glass is facing downward, and then the clarified solution is poured into the inner container. The liner is sealed in the autoclave, and the autoclave is placed in an oven at 150°C for 12 hours. After it is cooled to room temperature, the FTO glass is taken out and rinsed with deionized water to remove residual reaction. solution; then the FTO glass is annealed at 450°C, the annealing heating rate is controlled to be 2°C / min, and finally the TiO adhered on the surface of the FTO glass is obtained 2 nanorod arrays.

[002...

Embodiment 2

[0034] TiO 2 Nanorod array preparation: adding tetrabutyl titanate to hydrochloric acid solution and stirring to obtain a clear solution, the concentration of the hydrochloric acid solution is 15wt%, and the volume ratio of tetrabutyl titanate to hydrochloric acid solution is 1:58; The FTO glass that has been ultrasonically cleaned and dried by acetone, ethanol, and deionized water is placed obliquely in a polytetrafluoroethylene liner, with the conductive surface of the FTO glass facing down, and then the clarified solution is poured into the liner, Seal the liner in an autoclave, place the autoclave in an oven at 145°C for 11 hours, and take out the FTO glass after cooling to room temperature and rinse it with deionized water to remove the residual reaction solution; then The FTO glass is annealed at 430°C, and the annealing heating rate is controlled to be 1.5°C / min, and finally the TiO adhered on the surface of the FTO glass is obtained. 2 nanorod arrays.

[0035] Bi 2 ...

Embodiment 3

[0041] TiO 2 Nanorod array preparation: adding tetrabutyl titanate to hydrochloric acid solution and stirring to obtain a clear solution, the concentration of the hydrochloric acid solution is 20wt%, and the volume ratio of tetrabutyl titanate to hydrochloric acid solution is 1:62; The FTO glass that has been ultrasonically cleaned and dried by acetone, ethanol, and deionized water is placed obliquely in a polytetrafluoroethylene liner, with the conductive surface of the FTO glass facing down, and then the clarified solution is poured into the liner, Seal the liner in an autoclave, place the autoclave in an oven at 155°C for 13 hours, take out the FTO glass after cooling to room temperature and rinse with deionized water to remove the residual reaction solution; then The FTO glass is annealed at 470°C, the annealing heating rate is controlled at 2.5°C / min, and finally the TiO adhered on the surface of the FTO glass is obtained. 2 nanorod arrays.

[0042] Bi 2 S 3 / TiO 2 P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com