Preparation method of compound fertilizer by means of extrusion carbonization approach

A compound fertilizer and legal technology, applied in the field of compound fertilizer, can solve the problems of large amount of waste, poor environmental protection in the production process, low pelleting rate, etc., and achieve the effect of large adsorption area, low risk and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

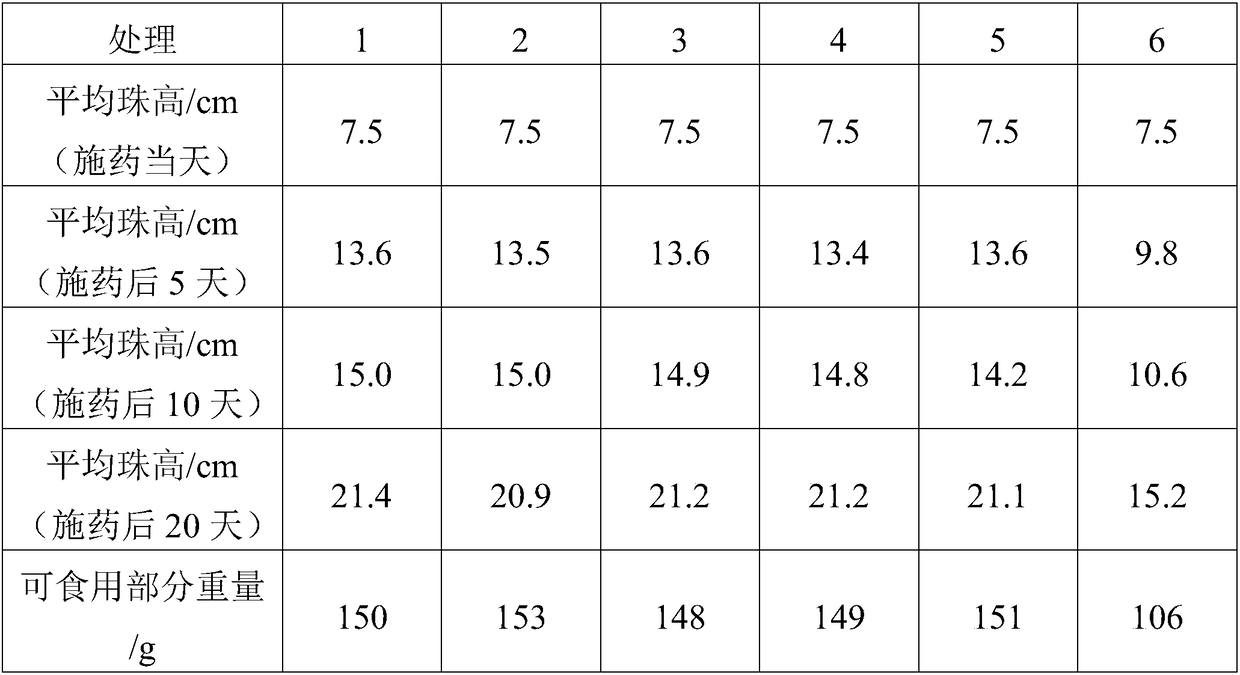

Examples

Embodiment 1

[0024] The present embodiment provides a kind of method that adopts extrusion carbon method to prepare compound fertilizer, comprises the following steps:

[0025] (1) In parts by weight, take 100 parts of urea, 20 parts of fulvic acid powder, and 12 parts of organic carbon powder for mixing, then melt in a stainless steel tank, stir, and the stirring intensity is 60 rpm, and add amino acid at the same time 10 parts of the solution, the melting temperature is 80-90°C, and the carbon mixture is obtained;

[0026] (2) In parts by weight, 420 parts of ammonium sulfate, 200 parts of potassium sulfate, and 230 parts of monoammonium phosphate are mixed with the carbon mixture. Secondary carbonization of the raw materials occurs, the extrusion temperature is 85°C, and then the extruded materials are sent to a screening and packaging system to obtain the product.

Embodiment 2

[0028] The present embodiment provides a kind of method that adopts extrusion carbon method to prepare compound fertilizer, comprises the following steps:

[0029] (1) In parts by weight, take 90 parts of urea, 25 parts of fulvic acid powder, and 10 parts of organic carbon powder for mixing, then melt in a stainless steel tank, stir, and the stirring intensity is 65 rpm, and add amino acid at the same time 8 parts of the solution, the melting temperature is 90°C, and the carbon mixture is obtained;

[0030] (2) In parts by weight, 400 parts of ammonium sulfate, 220 parts of potassium sulfate, and 200 parts of monoammonium phosphate are mixed with the carbon mixture. Secondary carbonization of the raw material occurs, the extrusion temperature is 90°C, and then the extruded material is sent to a screening and packaging system to obtain the product.

Embodiment 3

[0032] The present embodiment provides a kind of method that adopts extrusion carbon method to prepare compound fertilizer, comprises the following steps:

[0033] (1) In parts by weight, take 110 parts of urea, 15 parts of fulvic acid powder, and 15 parts of organic carbon powder for mixing, then melt in a stainless steel tank, stir, and the stirring intensity is 55 rpm, and add amino acid simultaneously 12 parts of the solution, the melting temperature is 80°C, and the carbon mixture is obtained;

[0034] (2) In parts by weight, 450 parts of ammonium sulfate, 180 parts of potassium sulfate, and 250 parts of monoammonium phosphate are mixed with the carbon mixture. Secondary carbonization of the raw material occurs, the extrusion temperature is 80°C, and then the extruded material is sent to a screening and packaging system to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com