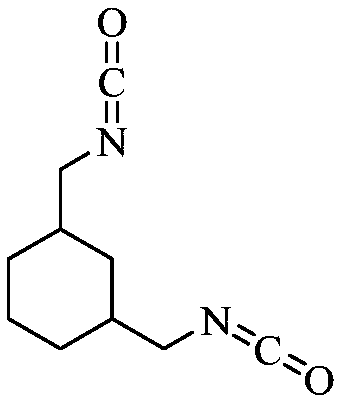

Synthesis method of 1,3-dimethyl isocyanate cyclohexane

A technology of dimethyl isocyanate and synthetic method, which is applied in the preparation of isocyanic acid derivatives, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of large solvent consumption, many side reactions, and low conversion rate, etc. Achieve the effect of short reaction time, easy operation and reduction of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 150ml o-dichlorobenzene into a 1000ml flask, start the stirring device, turn on the refrigeration device to cool down the flask, and when the temperature reaches 0°C, open the phosgene valve to start feeding phosgene, adjust the flow rate of phosgene at 12g / h, pre-pass Phosgene 0.5h. Mix 550ml of o-dichlorobenzene and 70g of 1,3-cyclohexanedimethylamine evenly, add to the dropping funnel, pre-flow phosgene for 0.5h, continue to pass phosgene, open the dropping valve at the same time, start to add o- For the mixed solution of dichlorobenzene and 1,3-cyclohexanedimethylamine, the dropping temperature was kept at 0°C. After 4 hours of dropping, the solution was in the form of white slurry, and the reaction was kept for 0.5 hours. Remove the freezing device, slowly raise the temperature to 130°C for 1 hour, and keep the reaction for 5 hours. During the reaction process, the slurry liquid gradually becomes thinner, and the color of the solution gradually changes from wh...

Embodiment 2

[0024] Add 150ml of monochlorobenzene into a 1000ml flask, start the stirring device, turn on the refrigeration device to cool down the flask, and when the temperature reaches 0°C, open the phosgene valve to start feeding phosgene, adjust the flow rate of phosgene at 12g / h, pre-pass Phosgene 0.5h. Mix 550ml of monochlorobenzene and 70g of 1,3-cyclohexanedimethylamine evenly, add to the dropping funnel, pre-flow phosgene for 0.5h, then continue to pass phosgene, and open the dropping valve of the funnel at the same time, start to drop to the reaction system Add a mixed solution of chlorobenzene and 1,3-cyclohexanedimethylamine, and keep the dropping temperature at 0°C. After 4 hours of dropping, the solution is in the form of white slurry, and keep warm for 0.5 hours. Remove the freezing device, slowly raise the temperature to 130°C for 1 hour, and keep the reaction for 5 hours. During the reaction process, the slurry liquid gradually becomes thinner, and the color of the solu...

Embodiment 3

[0027] Add 150ml of toluene into a 1000ml flask, start the stirring device, turn on the refrigeration device to cool down the flask, and when the temperature reaches 0°C, open the phosgene valve to start feeding phosgene, adjust the flow rate of phosgene at 12g / h, and pre-pass phosgene at 0.5 h. Mix 550ml of toluene and 70g of 1,3-cyclohexanedimethylamine evenly, add to the dropping funnel, pre-pass phosgene for 0.5h, continue to pass through phosgene, open the dropping valve of the funnel at the same time, start to drop toluene and For the mixed solution of 1,3-cyclohexanedimethylamine, the dropping temperature was kept at 0°C. After 4 hours of dropping, the solution was in the form of white slurry, and the reaction was kept for 0.5 hours. Remove the freezing device, slowly raise the temperature to 120°C for 1 hour, and keep the reaction for 5 hours. During the reaction process, the slurry liquid gradually becomes thinner, and the color of the solution gradually changes from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com