Preparation technology of high-wear resistance and self-repairing lubricating oil

A self-healing and preparation technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of vehicle life impact, high summer temperature, large operating load, etc., achieve excellent low temperature performance, reduce foam volume, and reduce dry wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

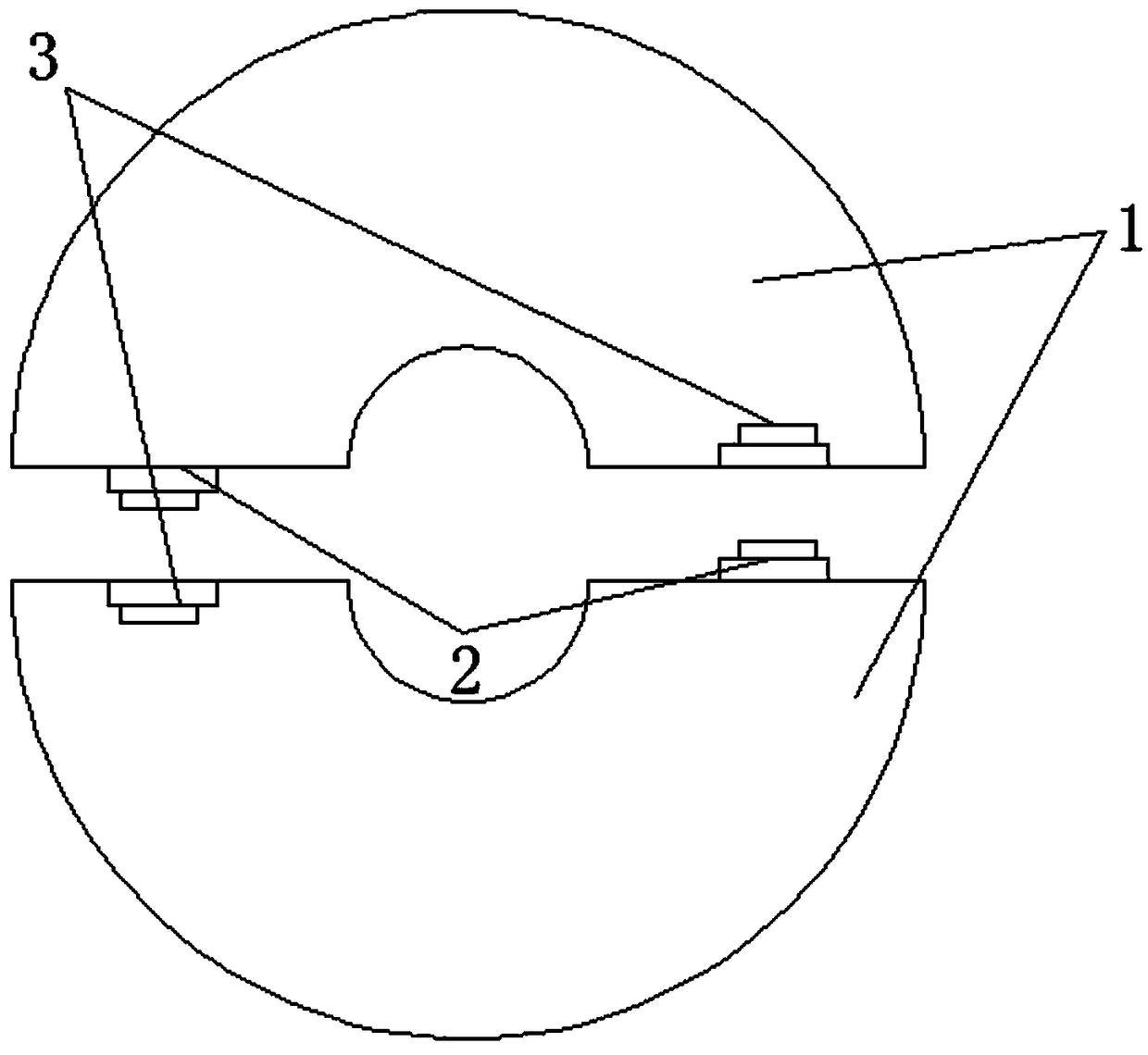

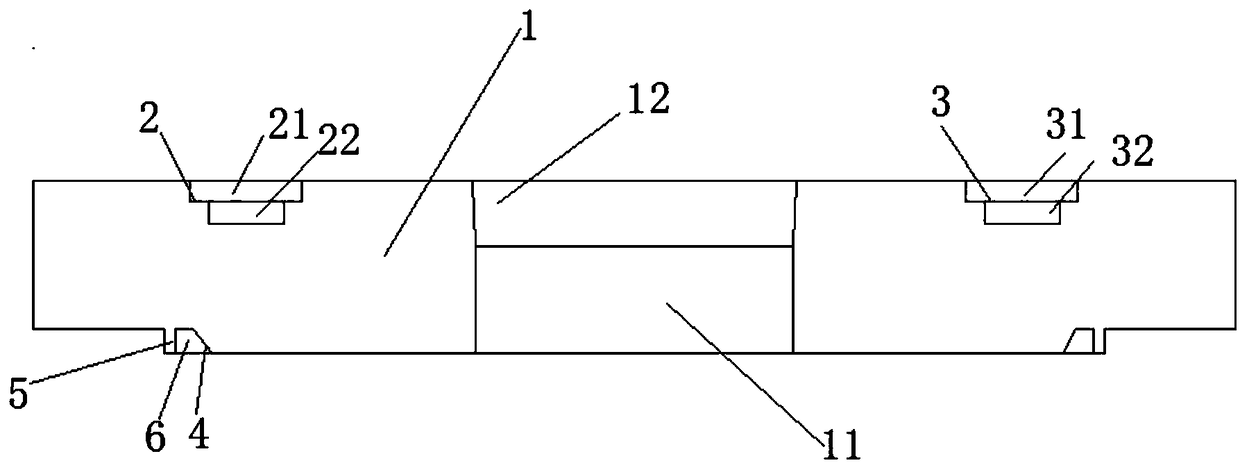

Image

Examples

Embodiment 1

[0037] This example shows a kind of high wear-resistant self-healing lubricating oil, according to the mass ratio, the components are as follows:

[0038] Hydroisomerization dewaxing III base oil accounts for 35%-45%, polyalphaolefin PAO accounts for 35%-45%, lubricating oil additives 10%-25%, and the described lubricating oil additive components include:

[0039] Nano calcium carbonate particle additive: 1%-2%;

[0040] Nano nickel particle additive 1%-2%;

[0041] Detergent and dispersant 2%-3%;

[0042] Antioxidant and anticorrosion agent 1.5%-2%;

[0043] Pour point depressant 0.3%-0.7%;

[0044] Viscosity index improver 6%-15%;

[0045] Defoamer 0.01%.

[0046] Furthermore, the nano-nickel particles were directly prepared by chemical law enforcement, and then surface-modified with oleic acid, and characterized by XRD and SEM.

[0047] Nano-nickel particles have a face-centered cubic structure with an average particle size of 40nm, and have good dispersion properties...

Embodiment 2

[0067] This example shows a process for preparing a highly wear-resistant self-healing lubricating oil, which specifically includes the following steps:

[0068] 1) Mix 35%-45% hydroisomerization dewaxing Group III base oil and 35%-45% polyalphaolefin PAO, stir at a constant speed, and heat to 48-58°C within 10 minutes, and keep warm for 20 minutes , to obtain base oil;

[0069] 2) Preparation of nano-calcium carbonate particle additives, specifically: preparation of nano-calcium carbonate particles: dissolving calcium chloride in a mixed solution of distilled water and absolute ethanol, adding acid additive solution and stirring at room temperature for 1 hour, then adding a certain amount of Stir the petroleum ether of oleic acid for 2 hours; after fully reacting, let stand to separate the liquid, take the upper part of the white turbid liquid and carry out rotary evaporation to remove excess solvent, dry in an oven to obtain nano calcium carbonate particles; finally prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com