Hot-blast stove chamber, drying system and drying method

A hearth and hot air technology, which is applied in the direction of drying, drying machine, heating to dry solid materials, etc., can solve the problems of limited design size, low heat exchange efficiency, waste, etc., to reduce heat loss and waste, and increase contact area , the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

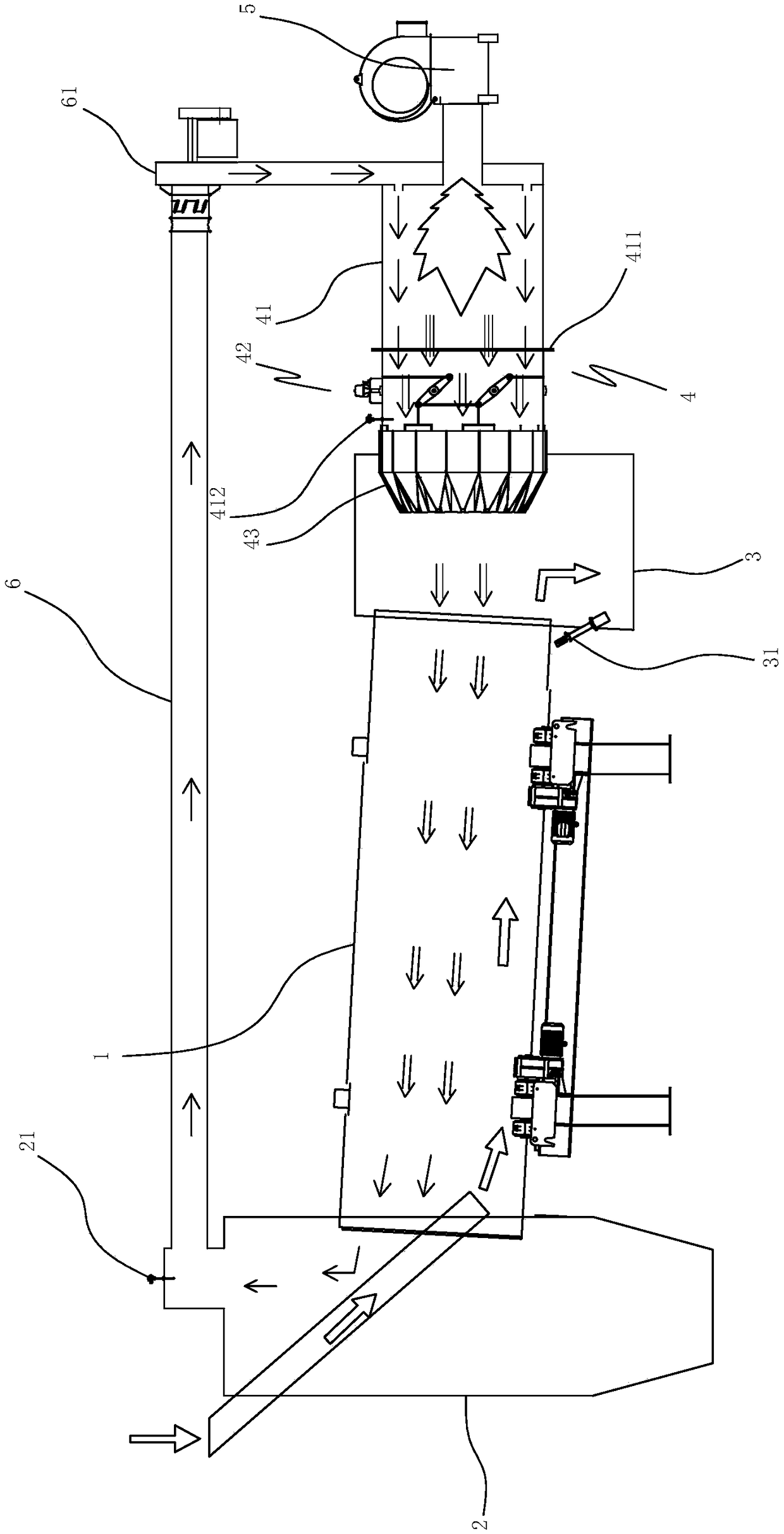

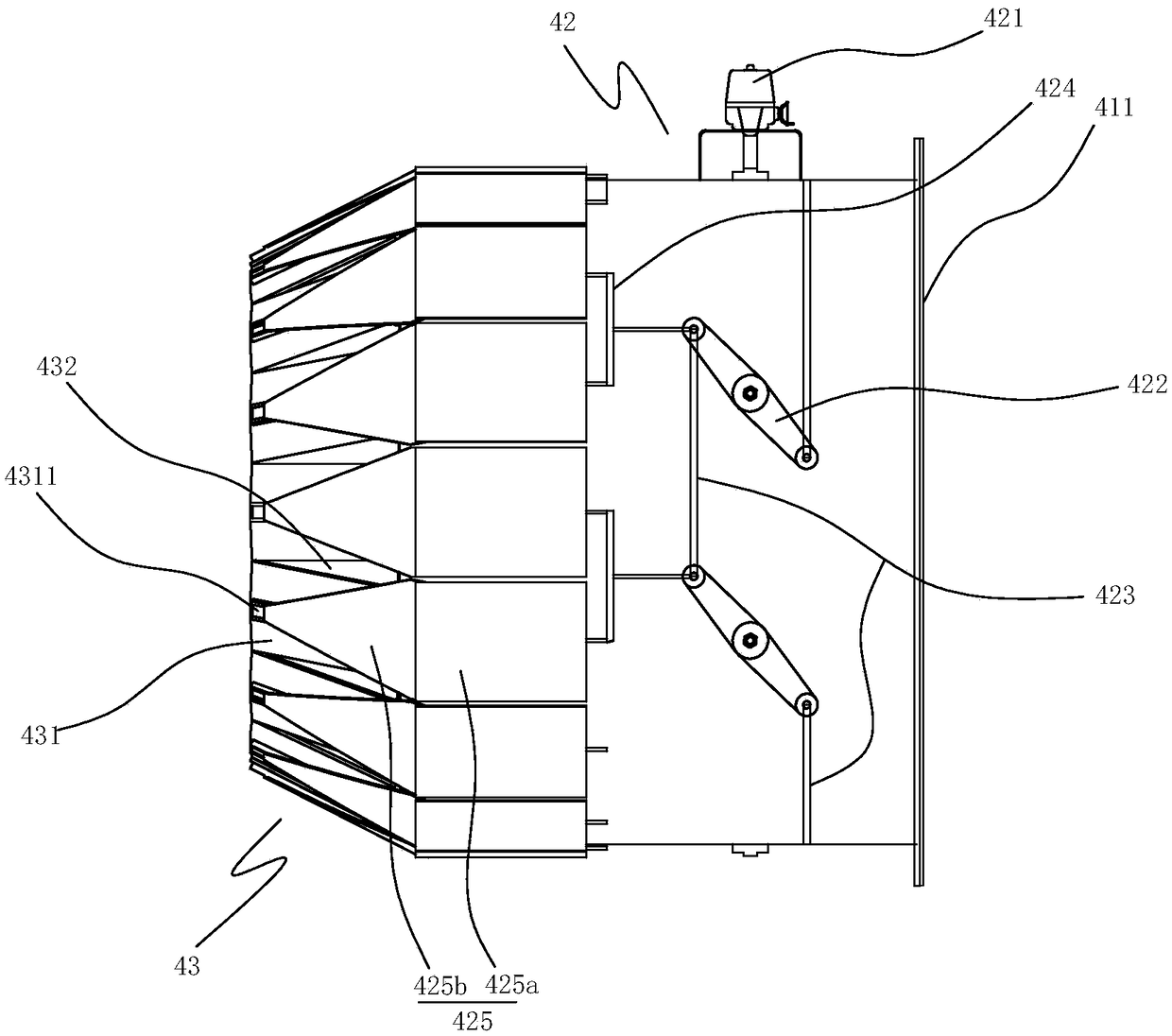

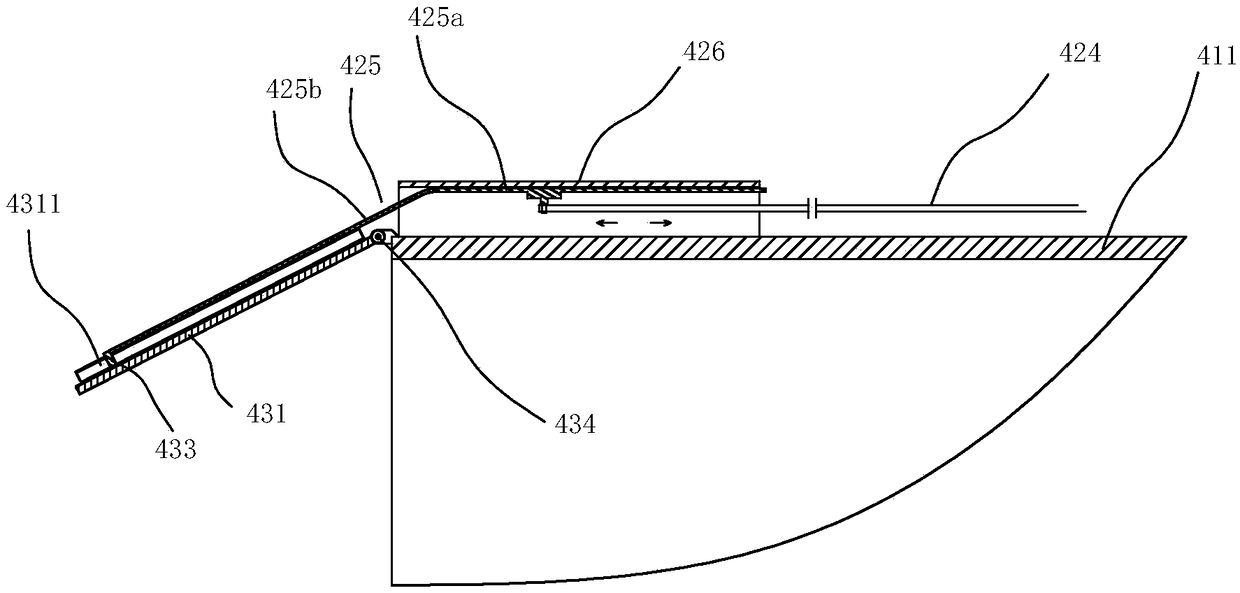

[0031] Embodiment one, with reference to Figure 1 to Figure 4 As shown, a countercurrent waste asphalt drying system includes a drying drum 1 arranged obliquely, a feed box 2 arranged at the high end of the drying drum 1, a discharge box 3 arranged at the low end of the drying drum 1, and a connecting outlet The hot-blast hearth 4 of the material box 3, the burner 5 connected to the hot-blast hearth 4, the return air duct 6 connected between the hot-blast furnace 4 and the feed box 2, the induced draft fan 61 arranged on the return air duct 6, The tail gas temperature sensor 21 on the top of the material box 2 , the furnace temperature sensor 412 arranged on the hot blast furnace 4 , and the discharge temperature sensor 31 arranged on the discharge box 3 .

[0032] The exhaust gas inside the feed box 2 is sent back to the hot blast furnace 4 through the return air duct 6, and the high-temperature flame ejected from the burner 8 is fully mixed and burned in the hot blast furna...

Embodiment 2

[0037] Embodiment two, refer to figure 2As mentioned above, it is a downstream waste asphalt drying system, which includes a drying drum 91 arranged obliquely, a feed box 93 arranged at the high end of the drying drum 91, a discharge box 92 arranged at the low end of the drying drum 91, and an inlet Material box 93 communicates with hot blast hearth 94, burner 95 connected with hot blast hearth 94, return air duct 96 that is connected between hot blast hearth 94 and discharge box 92, induced draft fan 961 that is arranged on the return air duct 96, is arranged on outlet The tail gas temperature sensor 921 at the top of the material box 92, the discharge temperature sensor 922 arranged at the bottom of the discharge, and the furnace temperature sensor 941 arranged at the hot blast furnace 94, the specific structure of the hot blast furnace 94 is the same as that of the first embodiment.

[0038] A method for drying waste asphalt, using the above-mentioned drying system, specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com