Preparation method of conductive silver paste for printed circuit

A technology of conductive silver paste and printed circuit, which is applied in the field of electronic information materials, can solve the problems of intolerance to bending and high resistance of conductive silver paste, and achieves the effects of excellent electrical conductivity, reduced silver content, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

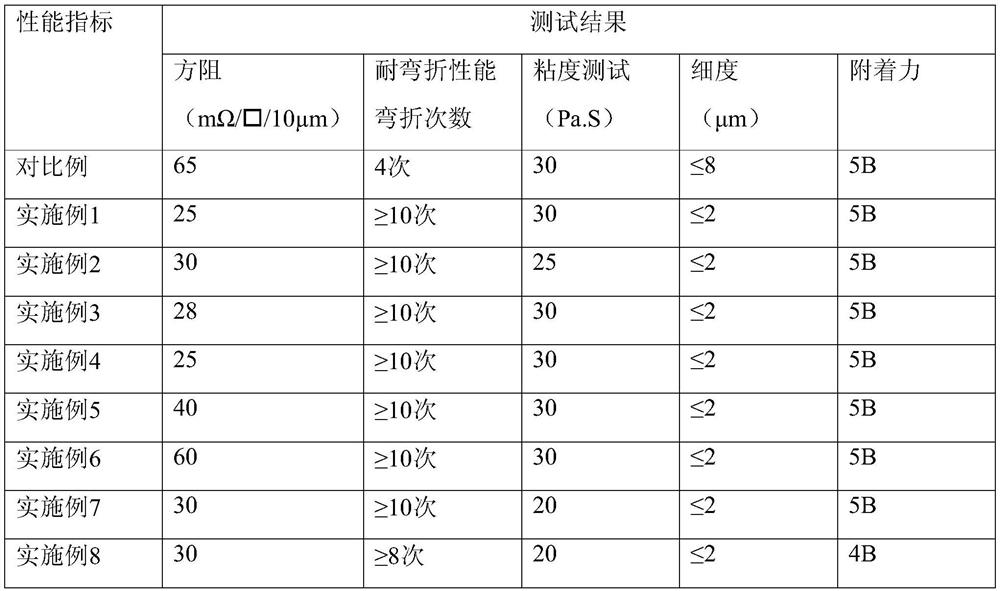

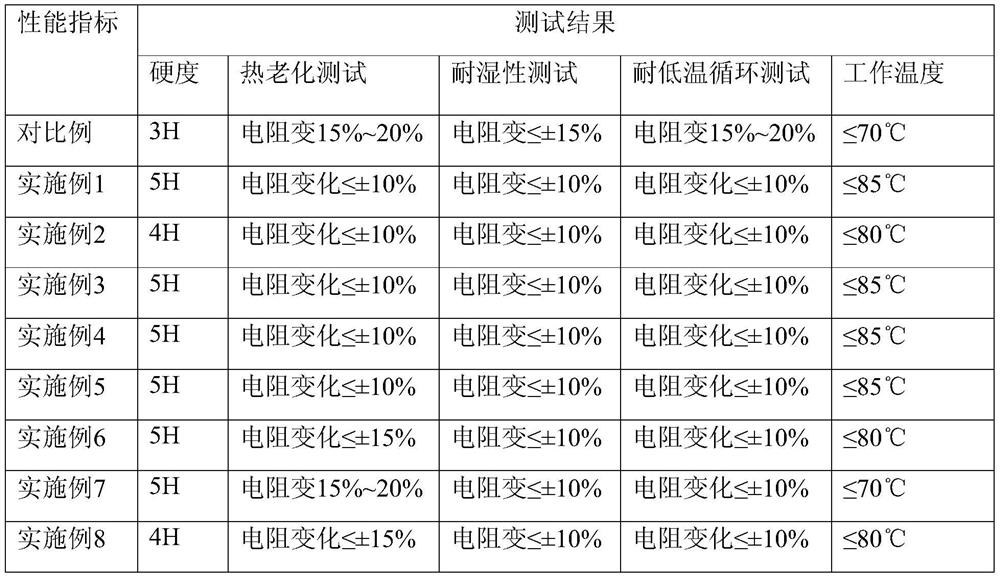

Examples

Embodiment 1

[0048] Step (1) prepare the required raw materials according to the following parts by weight ratio

[0049] Particle size 0.7μm~1.3μm, tap density 4g / cm 3 ~5g / cm 3 of spherical silver powder: 140g

[0050] Average particle size 1.2μm~1.8μm, tap density 4g / cm 3 ~5g / cm 3 flaky silver powder: 280g

[0051] Graphene with a particle size of 6nm to 8nm: 100g

[0052] Epoxy-modified polyester resin with an average molecular weight of 70,000 to 80,000: 120g

[0053] Propylene Glycol Methyl Ether Acetate: 140g

[0054] Spherical aluminum nitride with an average particle size of 50 nm to 1 μm: 10 g

[0055] Defoamer polyether modified siloxane: 7g

[0056] Leveling agent polyacrylate: 6g

[0057] Curing agent diaminodiphenyl sulfone: 8g.

[0058] A certain proportion of graphene is added to the raw materials used in the formula. Graphene is a new type of two-dimensional carbon material. 2 The hybrid orbitals form a hexagonal flat film with a honeycomb lattice, which has exce...

Embodiment 2

[0067] (1) Prepare the required raw materials according to the following proportions by weight

[0068] Step (1) prepare the required raw materials according to the following parts by weight ratio

[0069] Particle size 0.5μm~1.0μm, tap density 4g / cm 3 ~5g / cm 3 of spherical silver powder: 100g

[0070] Average particle size 1.0μm~1.5μm, tap density 4g / cm 3 ~5g / cm 3 flaky silver powder: 200g

[0071] Graphene with a particle size of 6nm to 8nm: 100g

[0072] Epoxy modified polyester resin with an average molecular weight of 50,000 to 70,000: 120g

[0073] Propylene Glycol Methyl Ether Acetate: 100g

[0074] Spherical aluminum nitride with an average particle size of 50 nm to 1 μm: 20 g

[0075] Defoamer polyether modified siloxane: 1g

[0076] Leveling agent polyacrylate: 1g

[0077] Curing agent diaminodiphenyl sulfone: 5g.

[0078] (2) Preparation of organic carrier

[0079] Add the epoxy modified polyester resin into the organic solvent, heat it to 70℃~80℃, fully...

Embodiment 3

[0083] (1) Prepare the required raw materials according to the following proportions by weight

[0084] Step (1) prepare the required raw materials according to the following parts by weight ratio

[0085] Particle size 1.0μm~1.5μm, tap density 3g / cm 3 ~4g / cm 3 of spherical silver powder: 150g

[0086] Average particle size 1.5μm~2.0μm, tap density 3g / cm 3 ~4g / cm 3 flaky silver powder: 300g

[0087] Graphene with a particle size of 6nm to 8nm: 70g

[0088] Epoxy modified polyester resin with an average molecular weight of 50,000 to 60,000: 80g

[0089] Propylene Glycol Methyl Ether Acetate: 150g

[0090] Spherical aluminum nitride with an average particle size of 50 nm to 1 μm: 12 g

[0091] Defoamer polyether modified siloxane: 6g

[0092] Leveling agent polyacrylate: 7g

[0093] Curing agent diaminodiphenylmethane: 12g.

[0094] (2) Preparation of organic carrier

[0095] Add the epoxy-modified polyester resin into the organic solvent, heat it to 70℃~80℃, stir fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com