Preparation method of nutritional tea rice paste

A technology of tea and rice nutrition, which is applied in the field of preparation of nutritious tea and rice dilute, can solve the problems of high price, complex preparation process, and overlap of efficacy selection, and achieve the effects of lowering blood sugar, rich nutrition, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

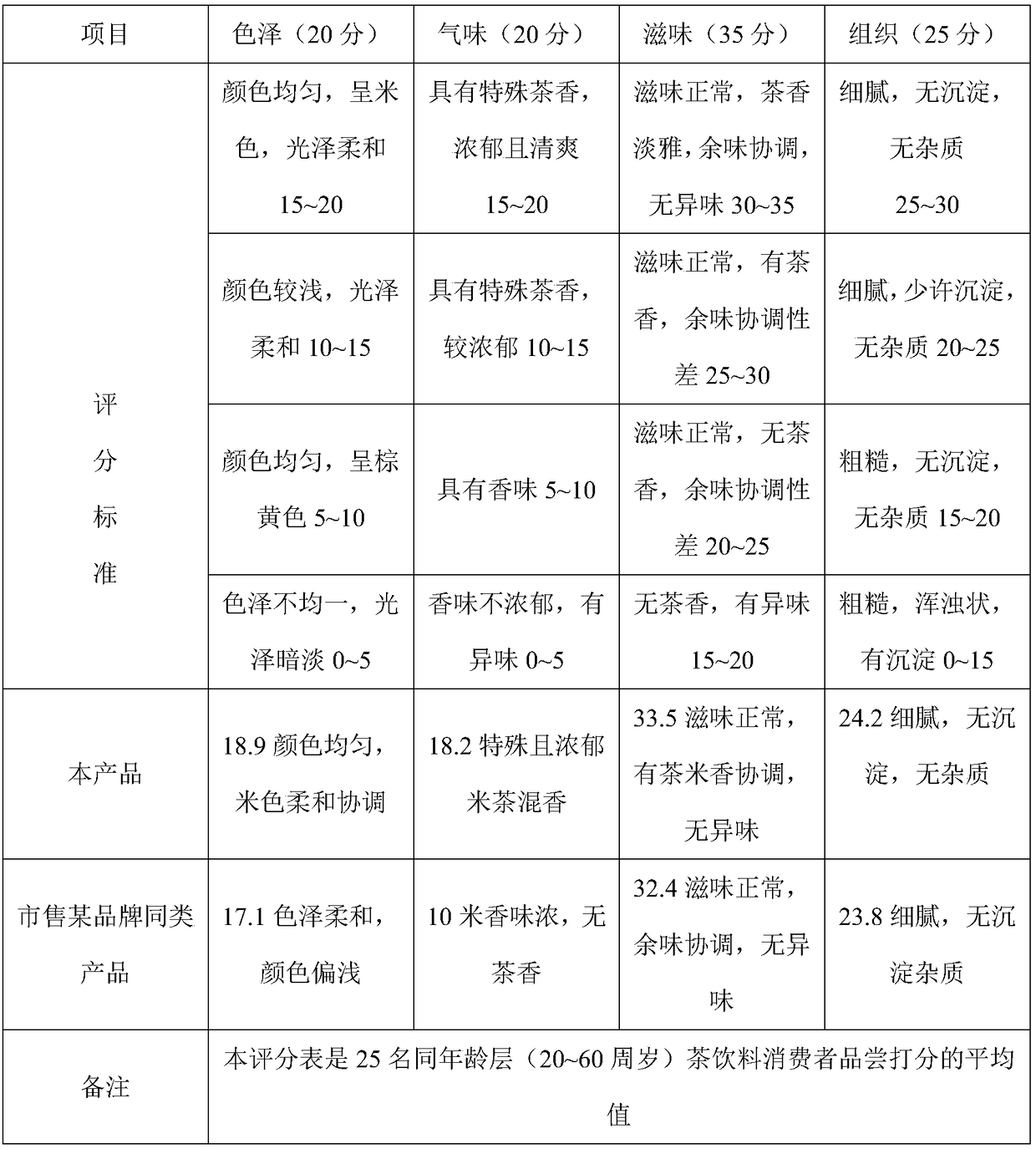

Image

Examples

Embodiment 1

[0027] The formula of nutritional rice thinner in this example is: 50 parts of japonica rice, 10 parts of tea leaves, 20 parts of South African leaves, 20 parts of Yunling, 10 parts of white lentils, 8 parts of lily, 9 parts of peony, 8 parts of tangerine peel, and 7 parts of licorice.

[0028] The preparation process is as follows:

[0029] (1) The above-mentioned raw materials are soaked respectively and impurities are removed;

[0030] (2) After the raw materials are pulverized and ground respectively, pass through an 80-mesh sieve;

[0031] (3) mixing each raw material after sieving to obtain a mixture;

[0032] (4) The mixture obtained in step (3) is subjected to secondary fine grinding, and the mixture is obtained through a 100-mesh sieve;

[0033] (5) gelatinize the mixture obtained in step (4) at 72° C. after absorbing water, and the gelatinization time is 30 minutes;

[0034] (6) steaming and maturing the gelatinized mixture in step (5), and steaming at 100° C. for...

Embodiment 2

[0039] The formula of nutritional rice thinner in this example is: 50 parts of japonica rice, 10 parts of tea leaves, 20 parts of South African leaves, 20 parts of Yunling, 10 parts of white lentils, 8 parts of lily, 9 parts of peony, 8 parts of tangerine peel, and 7 parts of licorice.

[0040] The preparation process is as follows:

[0041] (1) The above-mentioned raw materials are soaked respectively and impurities are removed;

[0042] (2) After the raw materials are pulverized and ground respectively, pass through an 80-mesh sieve;

[0043] (3) mixing each raw material after sieving to obtain a mixture;

[0044] (4) The mixture obtained in step (3) is subjected to secondary fine grinding, and the mixture is obtained through a 100-mesh sieve;

[0045] (5) gelatinize the mixture obtained in step (4) at 72° C. after absorbing water, and the gelatinization time is 30 minutes;

[0046] (6) steaming and maturing the gelatinized mixture in step (5), and steaming at 100° C. for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com